Preparation method of nanoflower-shaped zinc oxide

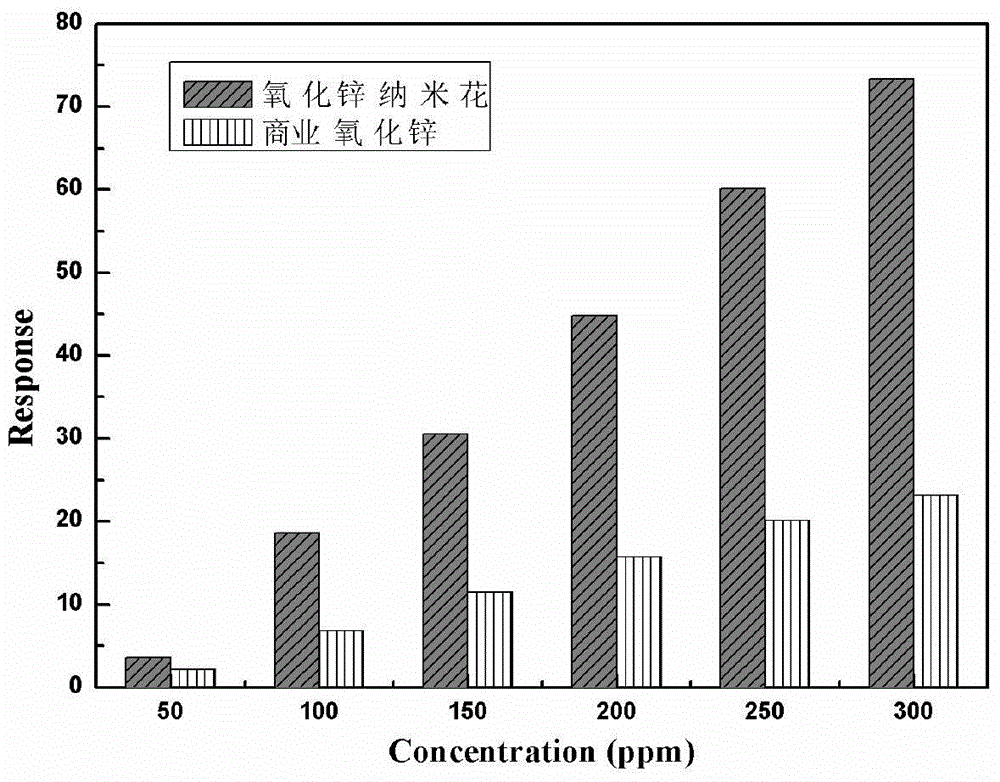

A flower-shaped zinc oxide and nano-technology, applied in the field of nano-materials, can solve the problems of poor shape integrity, cumbersome operation, and low controllability of nano-flower-shaped zinc oxide, and achieve simple and fast reaction routes, easy-to-obtain raw materials, and rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

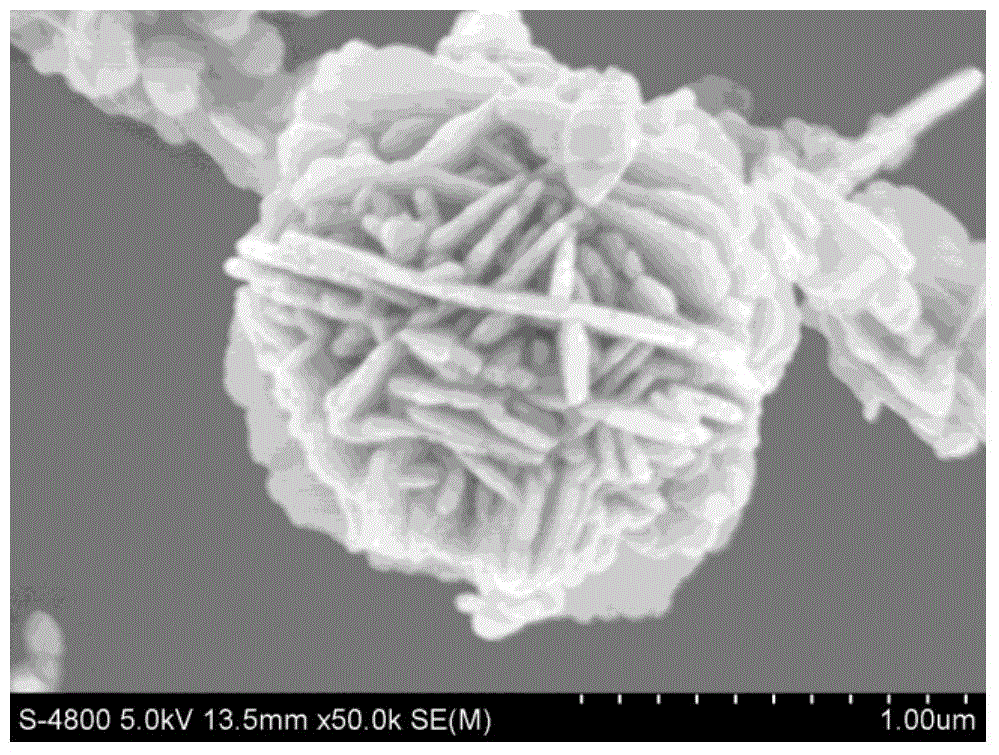

[0020] Take 2.7055g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 25ml of deionized water to prepare a 0.37mol / L zinc salt solution. Slowly add the potassium hydroxide solution dropwise into the zinc salt solution until the pH value of the zinc salt solution is 11 to form a reaction solution. Put the reaction solution in the polytetrafluoroethylene lining of the hydrothermal reaction kettle, screw the hydrothermal reaction kettle tightly, and place it in an oven. The temperature of the oven was raised to 200°C at a rate of 10°C / min. After a constant temperature reaction for 3 hours, the hydrothermal reactor was taken out and cooled at room temperature. The reaction solution was centrifuged to obtain a white precipitate, which was alternately washed with absolute ethanol and deionized water, and then dried in an oven at 80° C. to obtain ZnO powder with a nano-flower structure.

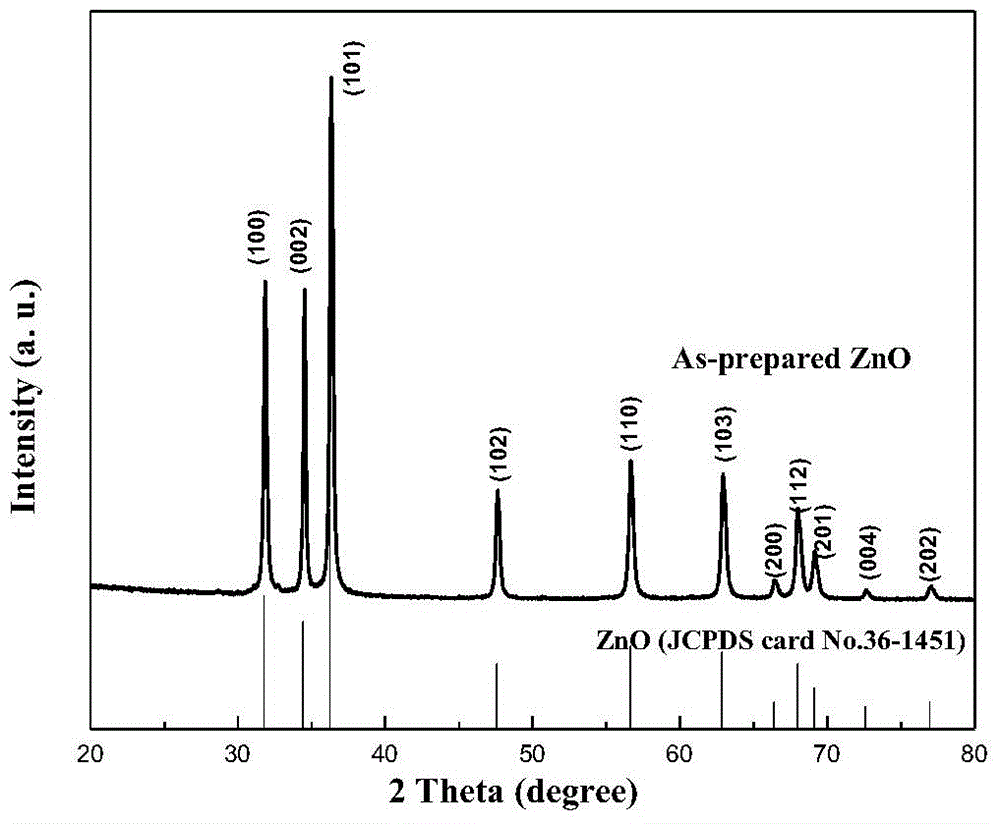

[0021] Such as figure 1 As shown, the prepared powder is subjected to XRD (X-ray diffraction) testing, a...

Embodiment 2

[0029] Take solid zinc sulfate and add deionized water to dissolve it to prepare a 0.15 mol / L zinc salt solution. Slowly add the sodium hydroxide solution dropwise into the zinc salt solution until the pH value of the zinc salt solution is 12 to form a reaction solution. Put the reaction solution in the polytetrafluoroethylene lining of the hydrothermal reaction kettle, screw the hydrothermal reaction kettle tightly, and place it in an oven. The temperature of the oven was raised to 120°C at a rate of 15°C / min. After a constant temperature reaction for 5 hours, the hydrothermal reactor was taken out and cooled at room temperature. The reaction solution was centrifuged to obtain a white precipitate, which was alternately washed with absolute ethanol and deionized water, and then dried in an oven at 60° C. to obtain ZnO powder with a nano-flower structure. The prepared powder is a flower-like structure composed of petal structures of nano-sheet units, wherein the thickness of t...

Embodiment 3

[0031] Take solid zinc acetate and add deionized water to dissolve, and prepare a 0.3mol / L zinc salt solution. Slowly add the potassium hydroxide solution dropwise into the zinc salt solution until the pH value of the zinc salt solution is 11 to form a reaction solution. Put the reaction solution in the polytetrafluoroethylene lining of the hydrothermal reaction kettle, screw the hydrothermal reaction kettle tightly, and place it in an oven. The oven was heated up to 140°C at a rate of 20°C / min, and after 4 hours of constant temperature reaction, the hydrothermal reactor was taken out and cooled at room temperature. The reaction solution was centrifuged to obtain a white precipitate, which was alternately washed with absolute ethanol and deionized water, and then dried in an oven at 70° C. to obtain ZnO powder with a nano-flower structure. The prepared powder is a flower-like structure composed of petal structures of nano-sheet units, wherein the thickness of the nano-sheet p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com