Complex phase transparent ceramic for white-light LED devices and preparation method of complex phase transparent ceramic

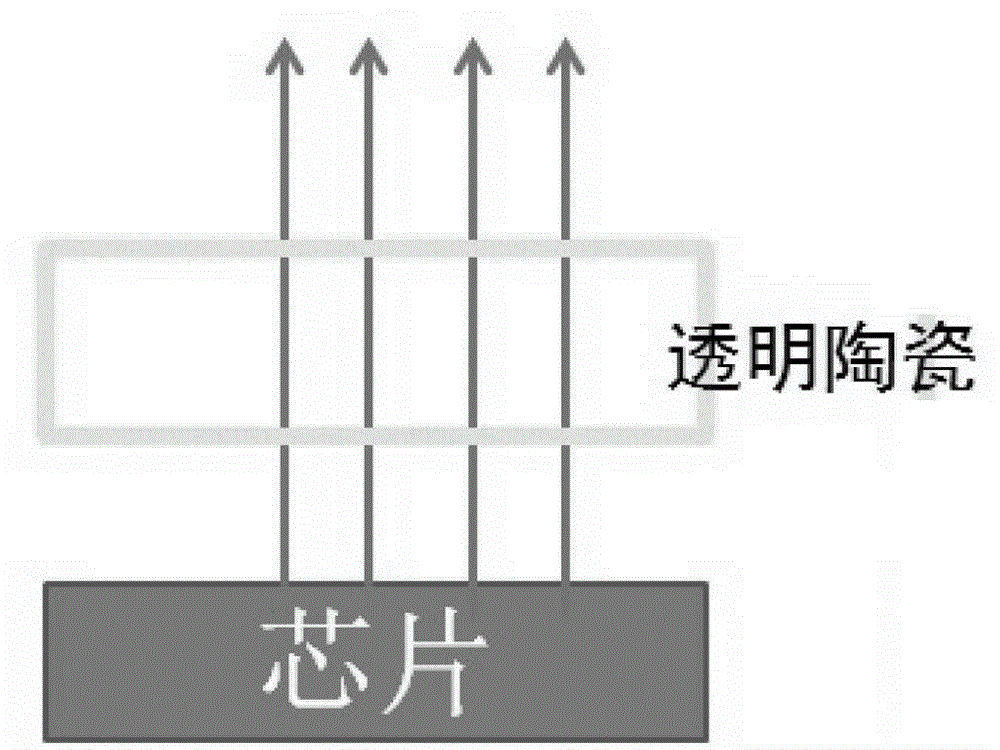

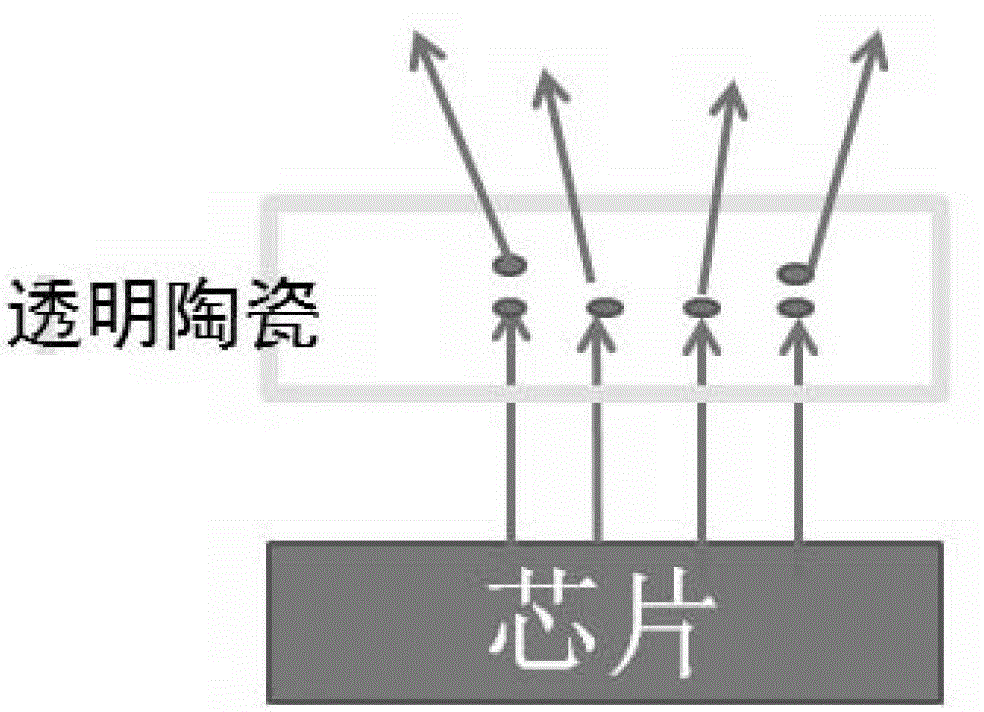

A technology of LED devices and transparent ceramics, applied in the field of bulk luminescent transparent ceramics, can solve the problems of insufficient mechanical and mechanical stability, limit the flexibility of processing and manufacturing, and reduce the service life of devices, so as to enhance the safety of human eyes and solve the problem of heat dissipation. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Another aspect of the present invention provides a method for preparing the multiphase transparent ceramic. As an example, the following steps may be included.

[0039] (1) Preparation of raw material mixed powder.

[0040] In one example, the raw material mixed powder can be prepared by a solid phase method. Specifically, weigh the yttrium oxide (Y 2 o 3 ), alumina (Al 2 o 3 ), cerium oxide (CeO 2 ), oxides of A, and nano-inorganic oxides with a refractive index of 2.0 to 2.5, wherein the oxide of A is Tb 2 o 3 、Pr 2 o 3 、Eu 2 o 3 、Nd 2 o 3 、Tm 2 o 3 , and Dy 2 o 3 At least one of the inorganic oxides with a refractive index of 2.0 to 2.5 is selected from TiO 2 , ZrO 2 , Nb 2 o 5 、 Ta 2 o 5 , HfO 2 , and at least one of ZnO, using water or ethanol as the ball milling medium, using alumina balls, steel balls, zirconium balls, or agate balls as the ball milling medium, these raw materials are wet ball milled and mixed uniformly and dried and sieve...

Embodiment 1

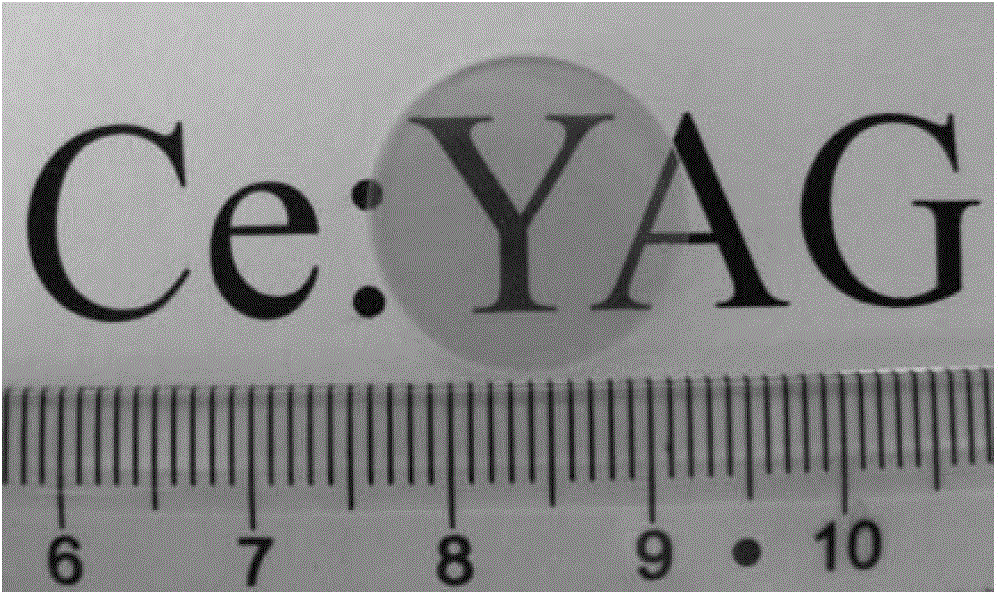

[0054] Example 1: 1wt%ZrO 2 -Ce 0.005 :Y 0.995 al 5 o 12 Composite ceramics

[0055] Using commercially available high-purity raw materials: Al 2 o 3 (>99.99%), Y 2 o 3 (>99.99%), CeO 2 (>99.99%), ZrO 2 (>99.99%) Weigh x=0.005, y=0.995 in proportion, use water or ethanol as ball milling medium, and use high-purity Al 2 o 3 The ball is used as the ball milling medium. On a high-energy ball mill, high-speed ball milling is carried out for 10-20 hours, and the ball milling speed is above 120rmp. After the slurry is dried and sieved, it is pressed into a green body by isostatic pressing (pressure not less than 150Mpa). Sintering under vacuum conditions, the temperature range is 1780 ° C for 40 hours, annealed in air for 20 hours, the annealing temperature range is 1450 ° C, and finally a dense and transparent composite ceramic ZrO 2 -Ce 0.005 :Y 0.995 al 5 o 12 . The emission angle of the transparent ceramic is measured by a light intensity distribution meter with...

Embodiment 2

[0056] Example 2: 0.5wt.%ZnO-Ce 0.005 :Y 0.995 al 5 o 12 Composite ceramics

[0057] Using commercially available high-purity raw materials: Al(NO 3 ) 3 (>99.99%), Y(NO 3 ) 3 (>99.99%), Ce(NO 3 ) 3 (>99.99%), dissolve in deionized water, weigh the solution in proportion x=0.005, y=0.995, use ammonia water as the precipitant, and prepare the precursor by co-precipitation method. After cleaning with deionized water and ethanol, calcined into Ce ; YAG nano-powder, and ZnO (>99.99%) nano-powder on the market, on a high-energy ball mill, high-speed ball milling for 10-20 hours, the ball milling speed is above 120rmp, after the slurry is dried and sieved, the isostatic pressing molding technology is used (Pressure not less than 150Mpa) pressed into a green body, the green body is sintered under vacuum conditions, the temperature range is 1720 ° C for 50 hours, annealed in air for 20 hours, the annealing temperature range is 1450 ° C, and finally a dense and transparent comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com