Preparation method of epoxy resin

An epoxy resin and epichlorohydrin technology, applied in the chemical industry, can solve the problems of increasing the cost of evaporating salt from saturated brine, consuming more hydrochloric acid, environmental pollution, etc., and achieving the effects of improving toughness, simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

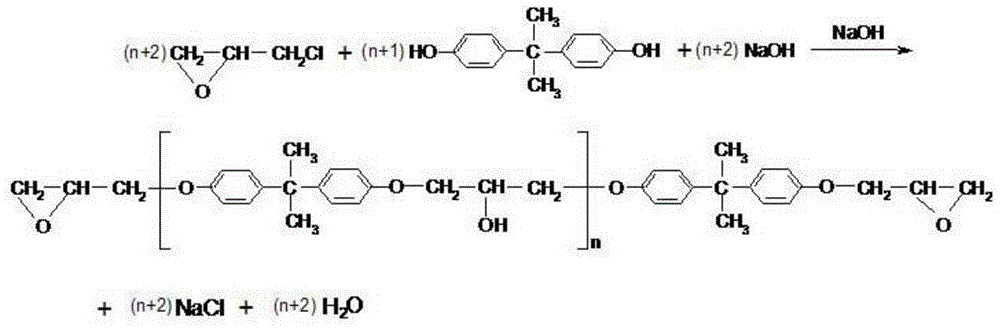

Method used

Image

Examples

Embodiment 1

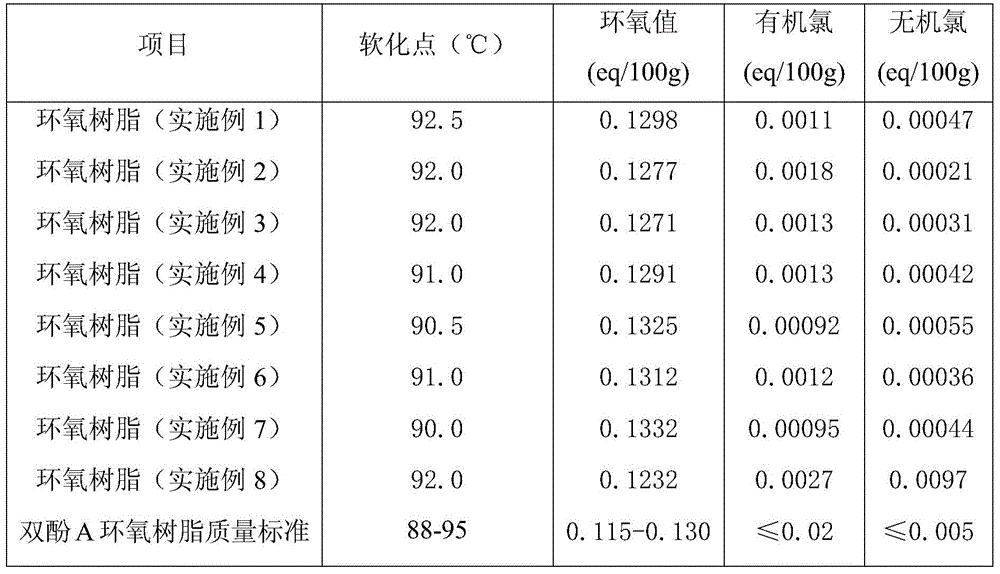

[0013] Embodiment 1: the preparation of epoxy resin

[0014] 1) In a 500ml four-necked flask with an electric heating mantle, agitator, and reflux condenser, add 198.4g of saturated brine (alkali content is 4.82%, COD 149940mg / L), 46.7g of NaOH solution with a mass fraction of 32%, turn on the stirrer, add 100g of bisphenol A, fully dissolve it at 40°C, and then add 52.5g of epichlorohydrin at one time for normal pressure The reaction is carried out in seven stages: 57±4°C, 15min; 70±3°C, 15min; 80±3°C, 30min; 85±3°C, 10min; 90±3°C, 10min; 95±2°C, 20min ;97±2℃, 20min, produce crude epoxy resin;

[0015] 2) The epoxy resin crude product was washed 7 times to neutrality, then dehydrated under normal pressure conditions, and then dehydrated under -0.095MPa vacuum conditions to obtain epoxy resin products with an epoxy value of 0.1298eq / 100g.

Embodiment 2

[0016] Embodiment 2: the preparation of epoxy resin

[0017] 1) In a 500ml four-neck flask with an electric heating mantle, agitator, and reflux condenser, add 237.0g of saturated brine produced during the production of benzyl glycidyl ether (the alkali content is 9.16%, and the COD is 179820mg / L) , 9.0g of NaOH solution with a mass fraction of 32%, start the stirrer, add 100g of bisphenol A, fully dissolve it at 40°C, then add 52.5g of epichlorohydrin at one time to carry out normal pressure reaction, the reaction is divided into seven Each stage: 57±4℃, 15min; 70±3℃, 15min; 80±3℃, 30min; 85±3℃, 10min; 90±3℃, 10min; 95±2℃, 20min; 97±2℃ , 20min, generate epoxy resin crude product;

[0018] 2) The crude epoxy resin product was washed 7 times to neutrality, then dehydrated under normal pressure conditions, and then dehydrated under -0.095MPa vacuum conditions to obtain epoxy resin products with an epoxy value of 0.1277eq / 100g.

Embodiment 3

[0019] Embodiment 3: the preparation of epoxy resin

[0020] 1) Add 233.5g C 12-14 Saturated brine (alkali content is 8.89%, COD is 183930mg / L) of by-product in the alkyl glycidyl ether production process, 11.7g mass fraction is the NaOH solution of 32%, open stirrer, add 100g bisphenol A, in Dissolve it fully at 40°C, then add 52.5g of epichlorohydrin at one time for normal pressure reaction, the reaction is divided into seven stages: 57±4°C, 15min; 70±3°C, 15min; 80±3°C, 30min ;85±3°C, 10min; 90±3°C, 10min; 95±2°C, 20min; 97±2°C, 20min, to produce crude epoxy resin;

[0021] 2) The crude epoxy resin product was washed 7 times to neutrality, then dehydrated under normal pressure conditions, and then dehydrated under -0.095MPa vacuum conditions to obtain epoxy resin products with an epoxy value of 0.1251eq / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com