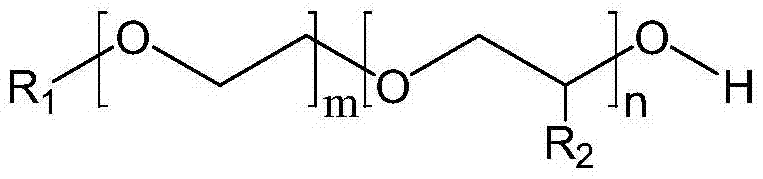

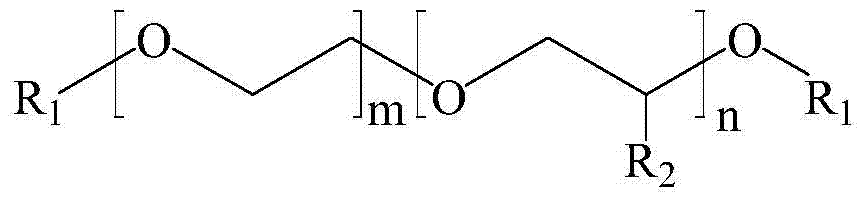

A kind of preparation method of diallyl terminated polyether

A technology of diallyl capping and allyl chloride, which is applied in the field of preparation of diallyl capping polyether, can solve the problem of unsuitable green chemical process and product color protection, limited intermediate polyether structure, propenyl Low degree of problems, to achieve the effects of reducing solvent recovery costs, mild reaction process, and lower viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put 1200g allyl alcohol polyoxyethylene ether (m=25.5, molecular weight 1200) and 52g NaOH into the reaction kettle, start stirring, put nitrogen in the kettle, add 68.9g allyl chloride at 25°C, and then Raise the temperature to 80°C for 4.5 hours; after the end, control the temperature in the kettle to 110°C, vacuumize to remove excess allyl chloride, dehydrate for 3 hours, then cool down to 85°C at 1°C / min, and continue to add 76.5g of allyl chloride Chlorine reacted for 4 hours, and the crude product was obtained so far; neutralizer, adsorbent and filter aid were added to the crude product, and refined to obtain the product bisallyl-terminated polyoxyethylene ether (m=25.5). Among them, the neutralizing agent is 50% phosphoric acid aqueous solution, and the addition amount is 25 g; the adsorbent is acid clay, and the addition amount is 6 g; the filter aid is diatomite, and the addition amount is 6 g.

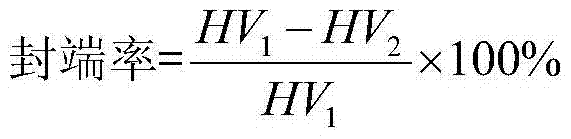

[0037] The end-capping rate of the finished bisallyl-terminated p...

Embodiment 2

[0039] Put 1200g allyl alcohol random polyether (m=24.6, n=6.6, molecular weight 1510) and 93.4g KOH into the reaction kettle, start stirring, and slowly add 103.4g allyl chloride at 30°C through nitrogen built into the kettle, Then heat up to 60°C at 2°C / min and react for 7 hours; after the end, control the temperature in the kettle to 110°C, vacuumize and degas and dehydrate for 3 hours, then cool down to 75°C at 2°C / min, and continue to add 24.3g allyl Chlorine reaction 4.5h, so far obtain crude product; (3) add neutralizer, adsorbent and filter aid in crude product, refine and obtain product bisallyl capped random polyether (m=24.6, n=6.6 ). Among them, the neutralizing agent is glacial acetic acid, and the addition amount is 53 g; the adsorbent is acid clay, and the addition amount is 12 g; the filter aid is diatomaceous earth, and the addition amount is 12 g.

[0040] The bisallyl terminated atactic polyether (m=24.6, n=6.6) obtained in this example has a capping rate o...

Embodiment 3

[0042]Put 1200g of allyl alcohol random polyether (m=23.5, n=4.6, molecular weight 1350), 106.7g of NaOH and KOH mixture (molar ratio is 1:1) into the reaction kettle, start stirring, and put nitrogen in the kettle, Slowly add 136g of allyl chloride at 20°C, then raise the temperature to 70°C at 0.5°C / min and react for 3 hours; after the end, control the temperature in the kettle to 115°C, vacuumize and degas and dehydrate for 3 hours, and then lower the temperature at 0.5°C / min To 80°C, continue to add 13.6g allyl chloride to react for 3h, so far to obtain the crude product; (3) add neutralizer, adsorbent and filter aid to the crude product, and refine to obtain the product diallyl-terminated random Polyether (m=23.5, n=4.6). Among them, the neutralizing agent is 50% phosphoric acid aqueous solution, and the addition amount is 87g; the adsorbent is acid clay, and the addition amount is 24g; the filter aid is diatomite, and the addition amount is 24g.

[0043] The bisallyl-te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com