Method for preparing straw fiber composite material

A technology of straw fiber and composite materials, which is applied in the field of composite fiber materials, can solve the problems of increased hydroxyl content on the fiber surface, difficulty in exerting a reinforcing effect, and reduced fiber strength, and achieves the effects of wide application, simple and reliable preparation method, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

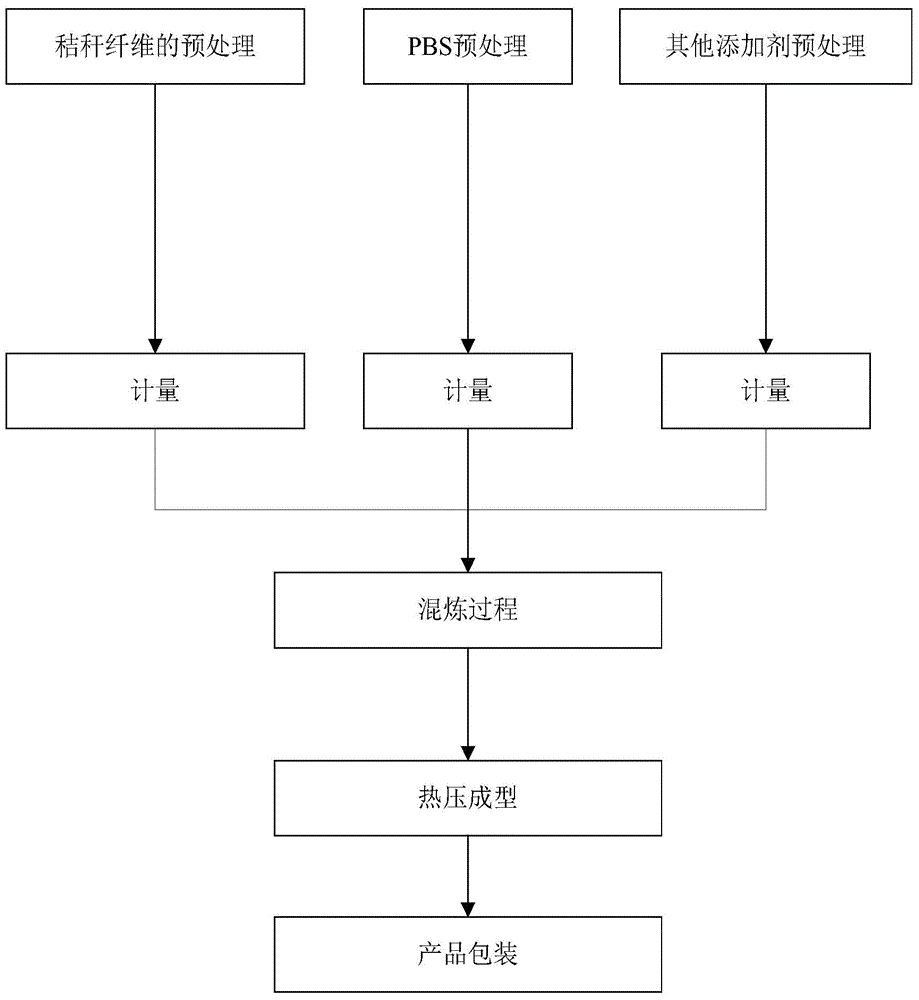

[0030] like figure 1 The schematic diagram of the process flow of the preparation method of the straw fiber composite material proposed by the present invention is shown, which mainly includes the following steps:

[0031] 1. Pretreatment of straw fiber:

[0032] 1) Select straw without mildew for mechanical treatment; after crushing and drying, short straw fibers of 100-150um are obtained;

[0033] 2) The straw is treated with water boiling process, the theoretical content of straw fiber is 40%, the mass fraction of NaOH solution is 8%, and it is heated and boiled. After comparison, the fiber content obtained twice in 30 minutes is the highest.

[0034] 3) Washing the separated straw fiber obtained after the boiling treatment to neutrality, and its pH value is 7;

[0035] 2. Mixing of straw fiber:

[0036]The mass fraction of straw fiber after pretreatment is 20%, polybutylene succinate (PBS) is pretreated, and polybutylene succinate (PBS) is placed in a vacuum drying ove...

Embodiment 2

[0041] like figure 1 The schematic diagram of the process flow of the preparation method of the straw fiber composite material proposed by the present invention is shown, which mainly includes the following steps:

[0042] 1. Pretreatment of straw fiber:

[0043] 1) Select straw without mildew for mechanical treatment; after crushing and drying, short straw fibers of 100-150um are obtained;

[0044] 2) The straw is treated with water boiling process, the theoretical content of straw fiber is 40%, the mass fraction of NaOH solution is 8%, and it is heated and boiled. After comparison, the fiber content obtained twice in 30 minutes is the highest.

[0045] 3) Washing the separated straw fiber obtained after the boiling treatment to neutrality, and its pH value is 7;

[0046] 2. Mixing of straw fiber:

[0047] The mass fraction of straw fiber after pretreatment is 25%, and the polybutylene succinate (PBS) is pretreated, and the polybutylene succinate (PBS) is placed in a vacu...

Embodiment 3

[0052] like figure 1 The schematic diagram of the process flow of the preparation method of the straw fiber composite material proposed by the present invention is shown, which mainly includes the following steps:

[0053] 1. Pretreatment of straw fiber:

[0054] 1) Select straw without mildew for mechanical treatment; after crushing and drying, short straw fibers of 100-150um are obtained;

[0055] 2) The straw is treated with water boiling process, the theoretical content of straw fiber is 40%, the mass fraction of NaOH solution is 8%, and it is heated and boiled. After comparison, the fiber content obtained twice in 30 minutes is the highest.

[0056] 3) Washing the separated straw fiber obtained after the boiling treatment to neutrality, and its pH value is 7;

[0057] 2. Mixing of straw fiber:

[0058] The mass fraction of straw fiber after pretreatment is 30%, and the polybutylene succinate (PBS) is pretreated, and the polybutylene succinate (PBS) is placed in a vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com