High-barrier isolated soybean protein edible membrane liquid as well as preparation method and application thereof

A technology of soybean protein isolate and high barrier property, applied in the field of food processing, can solve the problems of limited application and high price of enzyme preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

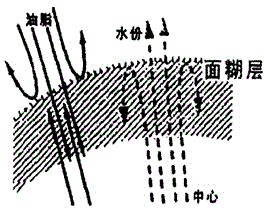

Method used

Image

Examples

Embodiment 1

[0033]Dissolve 50g of soybean protein isolate in 1L of distilled water, stir while adding, and then mix evenly with a high-speed mixer to prepare a 5% (w / v) soybean protein isolate solution. Pass the solution through a high-pressure homogenizer, and homogenize it for 10 minutes under the condition of 100 MPa. Take a certain amount of homogenized soybean solution and add 2.5% (w / v) glycerin to adjust the pH value of the solution to 8. Stir magnetically for 20 minutes at 70 ° C. Heat in a constant temperature water bath for 30 minutes, and cool to room temperature to obtain an edible film solution containing 50 g / L soybean protein isolate, 25 g / L glycerin, and 1.0 g / L glucose. Flow a part of the edible film solution through a straw into a petri dish (diameter 150mm) with polyvinyl chloride plastic inside, 18g of the solution in each petri dish, and scrape it with a curved glass rod to ensure that the thickness of the film is even. After natural drying, put The dried soybean prot...

Embodiment 2

[0035] Dissolve a certain quality of soybean protein isolate in distilled water, stir while adding, and then mix evenly with a high-speed mixer to prepare a 5% (w / v) soybean protein isolate solution. Pass the solution through a high-pressure homogenizer, under the condition of 100MPa, homogenize for 10 minutes, add 2.5% (w / v) glycerin, 0.1% (w / v) glucose, adjust the pH value of the solution to 8, stir magnetically for 20 minutes, 70 ℃ in a constant temperature water bath for 30 min, then cooled to room temperature. The remaining steps are the same as Example 1.

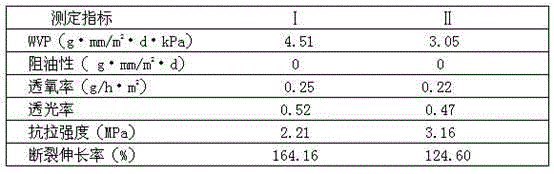

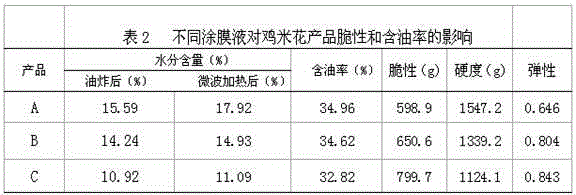

[0036] See Table 1 for the performance measurement of the edible film of soybean protein isolate prepared in the above-mentioned Example 1 and Example 2, and see Table 2 for the performance measurement of the product.

[0037] Table 1 Determination of edible film properties of soybean protein isolate

[0038]

[0039] Note: Ⅰ means that the film-forming solution is treated with high pressure 100MPa; Ⅱ means that...

Embodiment 3

[0043] The difference between this example and Example 2 is that the edible film liquid contains 40 g / L of soybean protein isolate, 20 g / L of glycerin, and 0.6 g / L of glucose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com