Regenerated high-performance lubricating grease of waste internal combustion engine oil and preparation method thereof

A waste internal combustion engine oil, high-performance technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as poor thermal stability, high energy consumption for solvent recovery, and low solvency, and achieve good lubricating performance and extreme pressure anti-wear performance , Realize the effect of low-cost recycling and low regeneration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

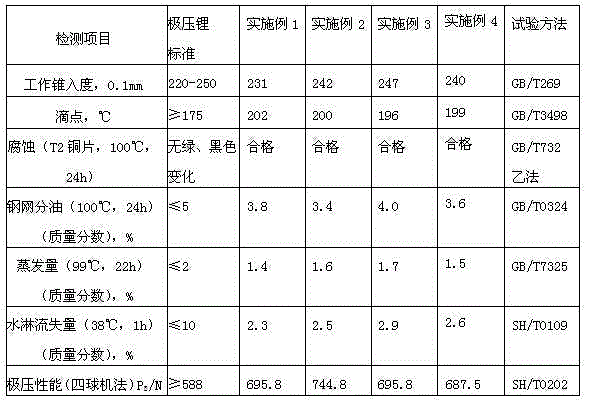

Examples

Embodiment 1

[0016] The waste internal combustion engine oil regenerated high-performance lubricating grease of the present embodiment is to be made from the raw material of following weight components:

[0017] (1) Waste internal combustion engine oil: 75%

[0018] (2) Lauryl hydroxystearic acid: 15%

[0019] (3) Lithium hydroxide: 1.8%

[0020] (4) Diphenylamine: 0.5%

[0021] (5) Borate: 1.5%

[0022] (6) Benzotriazole fatty amine salt compounds: 5.7%

[0023] (7) Ethylene-propylene copolymer: 0.5%.

[0024] The preparation method of the waste internal combustion engine oil regeneration high-performance lubricating grease of the present embodiment is as follows:

[0025] Add 187.5kg of waste internal combustion engine oil and 75kg of lauryl hydroxystearic acid into the reactor, heat slowly until the fatty acid is completely dissolved, dissolve 9kg of lithium hydroxide in water and add it into the reactor, and carry out saponification reaction at 100°C, and then heat up to 140°C Ad...

Embodiment 2

[0027] The waste internal combustion engine oil regenerated high-performance lubricating grease of the present embodiment is to be made from the raw material of following weight components:

[0028] (1) Waste internal combustion engine oil: 80%

[0029] (2) Fatty acid: 12%

[0030] (3) Lithium hydroxide: 1.9%

[0031] (4) Di-tert-butylcresol: 0.7%

[0032] (5) Sulfurized isobutylene: 1.0%

[0033] (6) Triethyl phosphate: 3.4%

[0034] (7) Random polypropylene: 1.0%.

[0035] The preparation method of the waste internal combustion engine oil regeneration high-performance lubricating grease of the present embodiment is as follows:

[0036] Add 200kg of waste internal combustion engine oil, 10kg of stearic acid, and 50kg of lauryl hydroxystearic acid into the reactor, heat slowly until the fatty acid is completely dissolved, dissolve 9.5kg of lithium hydroxide in water and add it to the reactor, and carry out saponification reaction at 110°C. After heating up to 140°C, add ...

Embodiment 3

[0038] The waste internal combustion engine oil regenerated high-performance lubricating grease of the present embodiment is to be made from the raw material of following weight components:

[0039] (1) Waste internal combustion engine oil: 85%

[0040] (2) Palmitic acid: 9.0%

[0041] (3) Lithium hydroxide: 2.0%

[0042] (4) Diphenylamine and di-tert-butylcresol: 1.0%

[0043] (5) Borate and sulfurized isobutylene: 0.5%

[0044] (6) Triethyl phosphate: 1.0%

[0045] (7) Ethylene-propylene copolymer: 1.5%.

[0046] The preparation method of the waste internal combustion engine oil regeneration high-performance lubricating grease of the present embodiment is as follows:

[0047] Add 212.5kg of waste internal combustion engine oil and 45kg of palmitic acid into the reactor, heat slowly until the fatty acid is completely dissolved, dissolve 10kg of lithium hydroxide in water and add it into the reactor, carry out saponification reaction at 105°C, add 106.25kg of waste oil af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com