Hot rolled steel strip with resistance to corrosion of hydrochloric acid and sulfuric acid and production method thereof

A production method, hydrochloric acid resistance technology, applied in the field of metallurgy, to achieve the effect of excellent corrosion resistance and excellent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

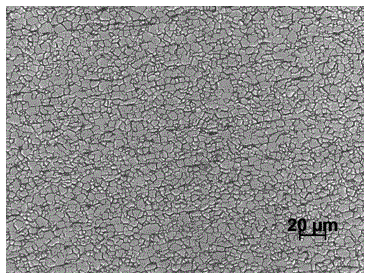

Image

Examples

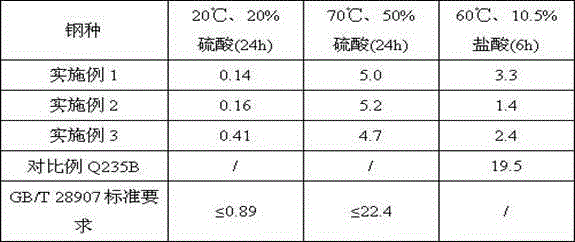

Embodiment 1

[0015] The hydrochloric acid and sulfuric acid corrosion-resistant hot-rolled steel strip in this embodiment includes the following components by weight percentage: C: 0.04%, Si: 0.30%, Mn: 1.19%, P: 0.009%, S: 0.026%, Ni: 0.18% , Cr: 0.03%, Cu: 0.38%, Nb: 0.001%, Sb: 0.11%, Sn: 0.07%, Ca: 0.0010%, Alt: 0.025%, N: 0.0036%, the rest is iron and unavoidable impurities.

[0016] The production process of the hydrochloric acid and sulfuric acid corrosion-resistant hot-rolled steel strip in this embodiment is produced by a three-roll mill, including a converter or electric furnace smelting process, an out-of-furnace refining process, a continuous casting process, a rolling process, and a coiling process; The heating temperature of the billet is 1200℃, and the heating time is 2 hours and 30 minutes. It is rolled into a steel strip with a thickness of 2.5mm. The rough rolling start temperature: 1140℃, the start rolling temperature of the continuous rolling mill: 1070℃, the final rolling ...

Embodiment 2

[0018] The hydrochloric acid and sulfuric acid corrosion-resistant hot-rolled steel strip in this embodiment includes the following components by weight percentage: C: 0.05%, Si: 0.32%, Mn: 1.05%, P: 0.011%, S: 0.008%, Ni: 0.23% , Cr: 0.08%, Cu: 0.47%, Mo: 0.11%, Nb: 0.051%, Ti: 0.012%, Sb: 0.090%, RE: 0.028%, Ca: 0.0015%, Alt: 0.043%, N: 0.0045% , The rest is iron and inevitable impurities;

[0019] The production process of the hydrochloric acid and sulfuric acid corrosion-resistant hot-rolled steel strip in this embodiment is produced by a three-roll mill, including a converter or electric furnace smelting process, an out-of-furnace refining process, a continuous casting process, a rolling process, and a coiling process; Billet heating temperature: 1160℃, heating time 4 hours and 10 minutes, rolled into a steel strip with a thickness of 2.75mm, rough rolling opening temperature: 1100℃, entering the continuous rolling mill opening temperature: 890℃, final rolling temperature: 7...

Embodiment 3

[0021] The hydrochloric acid and sulfuric acid corrosion-resistant hot-rolled steel strip of this embodiment includes the following components by weight percentage:

[0022] C: 0.06%, Si: 0.35%, Mn: 0.85%, P: 0.015%, S: 0.022%, Ni: 0.11%, Cr: 0.03%, Cu: 0.29%, Nb: 0.020%, Ti: 0.050%, V: 0.020%, Sb: 0.10%, Ca: 0.0030%, Alt: 0.031%, N: 0.0065%, the rest is iron and unavoidable impurities;

[0023] The production process of the hydrochloric acid and sulfuric acid corrosion-resistant hot-rolled steel strip in this embodiment is produced by a three-roll mill, including a converter or electric furnace smelting process, an out-of-furnace refining process, a continuous casting process, a rolling process, and a coiling process; Billet heating temperature: 1180℃, heating time 3 hours and 30 minutes, rolled into a steel strip with a thickness of 10mm, rough rolling opening temperature: 1140℃, entering the continuous rolling mill opening temperature: 980℃, final rolling temperature: 900℃ , Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com