Method for preparing ultrafine grain titanium alloy by using alpha'' orthorhombic martensite microstructure

A technology of orthorhombic martensite and titanium alloys, which is applied in the field of preparation of ultra-fine-grained titanium alloys to achieve the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

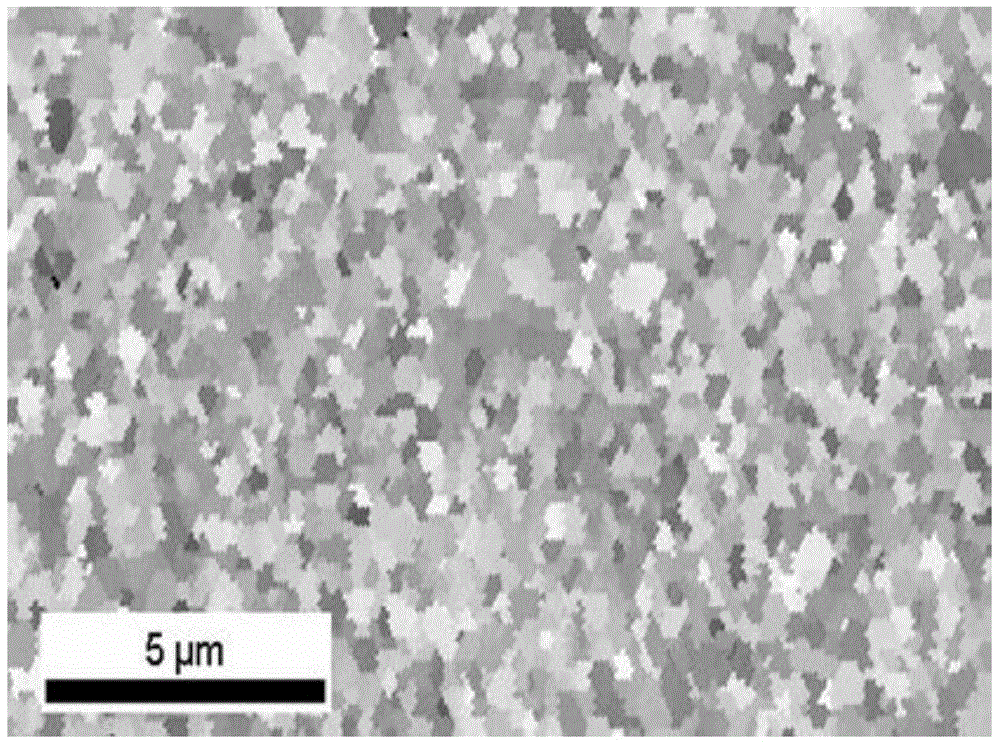

[0025] A Ti-6Al-2Sn-2Zr-3Mo-1Cr-2Nb-0.1Si (TC21, Mo equivalent of 5.27) alloy hot-forged sample with a size of Ф40×60mm was used. By measuring its phase transition point T β About 965°C. Put the sample in a vacuum of 1×10 -3 Heating to 1000°C in a vacuum state of Pa, and quenching and cooling to room temperature with water after holding for 1 hour, the XRD analysis of the product shows that the quenched alloy is mainly composed of α"orthorhombic martensite. Then the sample is heated by induction Heating to the deformation temperature of 750°C, holding the temperature for 3 minutes, and forging on the hot forging machine, the deformation strain rate is about 20s -1 , with a total deformation of 68%, jet cooling after the forging is completed. Finally, the forged titanium alloy is subjected to stress relief annealing treatment in a vacuum heat treatment furnace at a treatment temperature of 450° C. for 4 hours, and air-cooled to room temperature. The microstructure of the de...

Embodiment 2

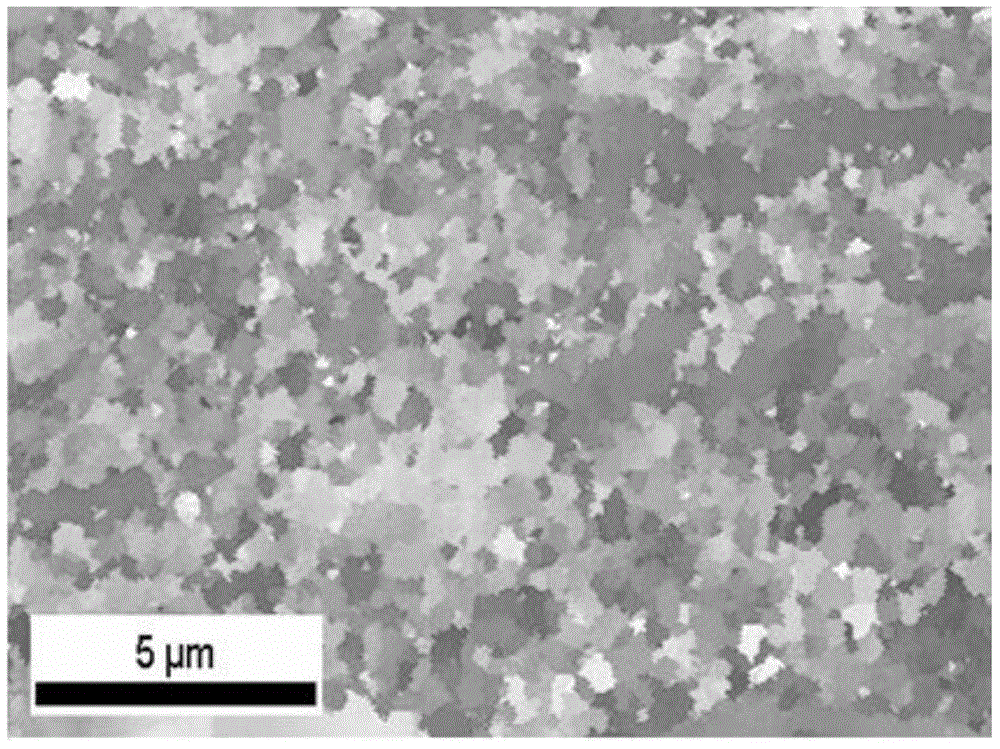

[0027] A Ti-3Al-4Mo-4.5V (Mo equivalent of 7.2) alloy hot-forged bar with a size of Ф35×50mm was used. By measuring its phase transition point T β About 870°C. Put the bar in a vacuum of 1×10 -3 Heating to 900°C under Pa vacuum, keeping it warm for 1.5 hours, then quenching and cooling to room temperature with helium+nitrogen mixed gas. The XRD analysis of the product shows that the quenched alloy is mainly composed of α"orthorhombic martensite. Then the quenched bar is heated to the deformation temperature of 680°C by induction heating, and kept for 5 minutes. Extrusion deformation is carried out on the hot extrusion machine, the extrusion ratio is 5, and the jet cooling is carried out after the extrusion is completed. Finally, the extruded titanium alloy is subjected to stress relief annealing treatment in a vacuum heat treatment furnace, the treatment temperature is 400 ° C, and the time is 3 Hours, air-cooled to room temperature. The microstructure of the deformed Ti-3A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com