Method for manufacturing polymer PMMA optical waveguide device based on electric printing technology

A polymer, electro-printing technology, used in optical waveguides, light guides, optical components, etc., can solve problems such as high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

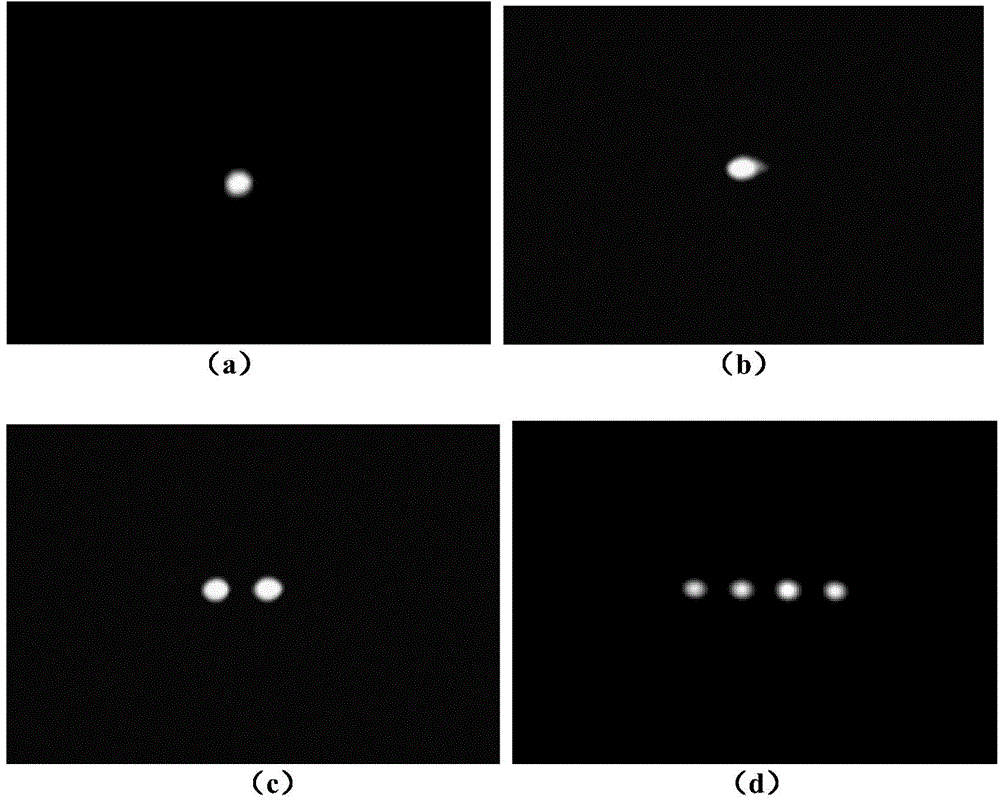

Image

Examples

Embodiment 1

[0062] Embodiment 1: Preparation and Refractive Index Characterization of PMMA Core Material

[0063] The core material used in the present invention is a polymer—polymethyl methacrylate, which can be prepared by copolymerizing methyl methacrylate, and the prepared material has high transparency and good film-forming properties. , low price and easy synthesis, etc., are widely used in polymer planar optical waveguide devices. Its molecular structural formula is shown in general formula (I).

[0064]

[0065] The obtained PMMA material was spin-coated on a cleaned Si substrate (a total of 4 samples) by a spin-coating process, and then the spin-coated polymer film was placed in a vacuum oven for low-temperature curing (30 ° C) for 2.5 hours. Remove the solvent from the film. Next, 4 identical samples were cured at curing temperatures of 30°C, 60°C, 90°C, 120°C, 150°C and 180°C for 2 hours respectively, and the refractive index of the material was measured with an ellipsomet...

Embodiment 2

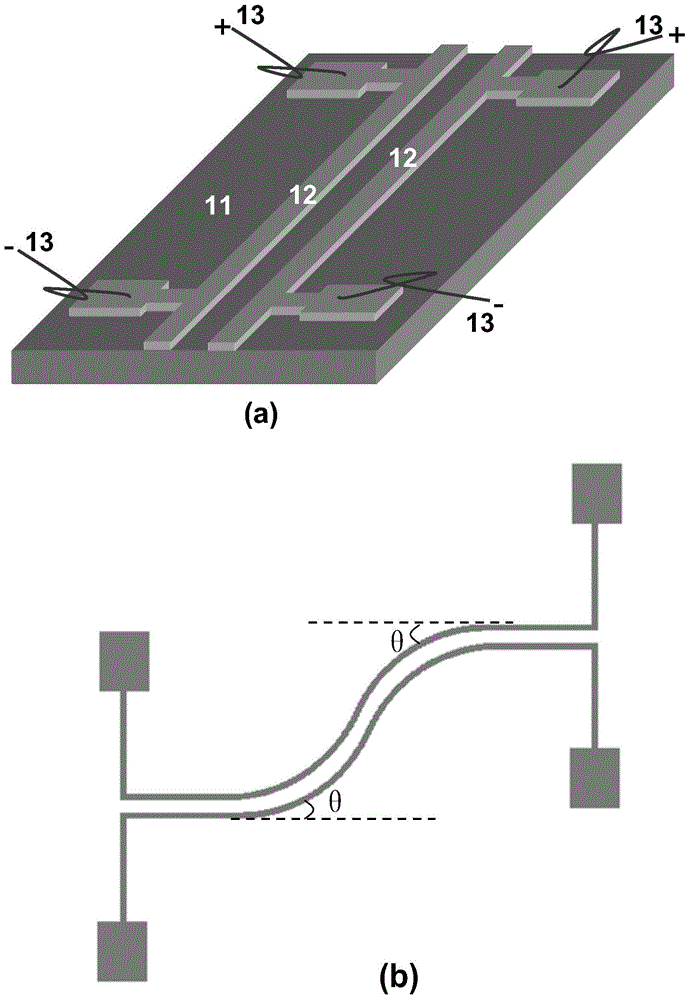

[0066] Embodiment 2: prepare electroprinting template on PMMA substrate

[0067] First, clean the PMMA substrate. A PMMA substrate (thickness 2 mm) with low price and low thermal conductivity was selected as the substrate of the electroprinting template, which was repeatedly wiped with acetone and ethanol cotton balls in sequence, rinsed with deionized water, and finally dried with nitrogen .

[0068] Then, integrated electrode wiring is prepared. A layer of aluminum film with a thickness of 300nm was evaporated on the cleaned PMMA substrate by evaporation process, and then a layer of BP212 positive photoresist with a thickness of 2 μm was spin-coated on the aluminum film by spin coating process. Pre-bake for 20 minutes at ℃; then, on the photolithography machine, put it in close contact with the electrode mask plate (chrome plate) complementary to the waveguide to carry out the photolithography of the plate. The exposure time of the photoresist is 7 seconds, and the mask is...

Embodiment 3

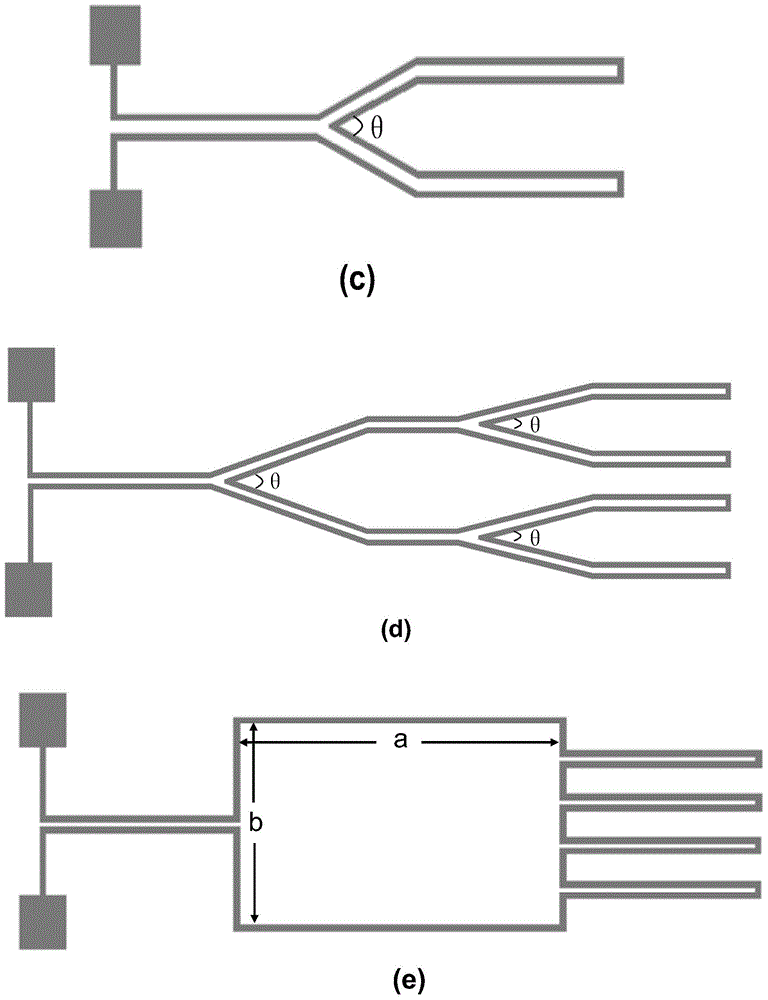

[0070] Example 3: Using electroprinting technology on SiO 2 Preparation of Polymer PMMA Optical Waveguide on Substrate

[0071] First, a layer of SiO with a thickness of 3 μm is grown on the silicon substrate 2 Lower confinement layer (lower cladding). In order to suppress the leakage of the light field into the silicon substrate with a higher refractive index, a thicker layer of SiO needs to be grown on the silicon wafer. 2 The lower confinement layer is used as the lower cladding layer of the waveguide, and the method of dry oxygen oxidation and wet oxygen oxidation is used to grow SiO 2 layer, the oxidation temperature was kept at 1200°C, dry oxygen oxidation was performed for 30 minutes first, then wet oxygen oxidation and dry oxygen oxidation were alternately carried out 6 times, among which wet oxygen oxidation was 60 minutes, dry oxygen oxidation was 30 minutes, and finally dry oxygen oxidation was 30 minutes , and finally a silicon dioxide lower cladding layer with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com