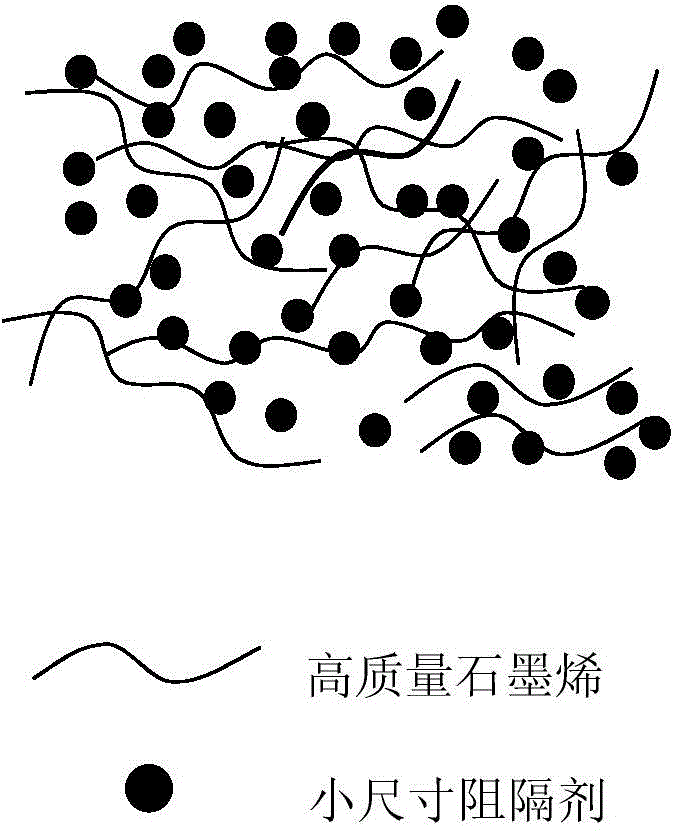

Small-blocking-agent-loaded graphene conductive slurry and preparation method and application thereof

A conductive paste, graphene technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc. problems, to achieve the effects of excellent electrical conductivity, improved performance, and elimination of stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

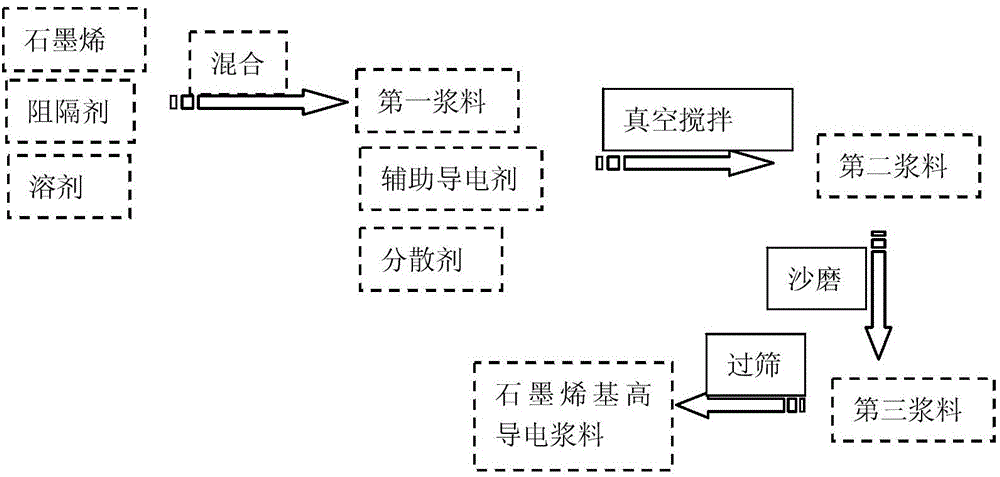

[0034] Another aspect of the present invention provides a kind of preparation method of the graphene conductive paste of loading small size barrier agent, please refer to figure 2 , in a typical implementation, it includes the following steps:

[0035] a, Graphene, small size barrier agent and solvent (dispersant) are mixed uniformly, obtain the first slurry;

[0036] b. Mixing the first slurry with the auxiliary conductive component and the dispersant under vacuum stirring to obtain the second slurry;

[0037] c. Sand grinding and sieving the second slurry to obtain the final highly conductive graphene slurry.

Embodiment 1

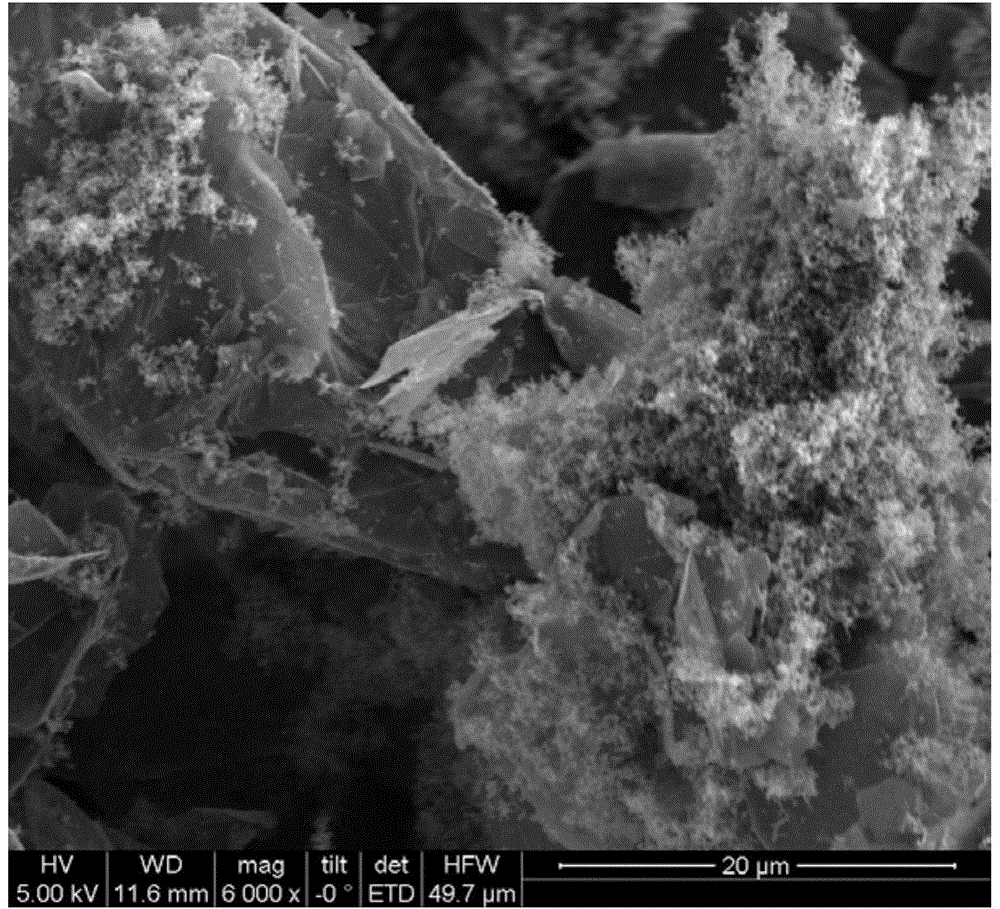

[0040] Take 30g of high-quality graphene powder (the average thickness is 3nm, the average sheet size is 20μm, and the average conductivity of the dry powder film is 10 5 S / m) and 10g carbon black are stirred in ethanol and ultrasonically 1h, after mixing evenly, dry at 80 ℃ to obtain the graphene powder of surface adsorption carbon black (such as image 3 ). The powder was stirred with 10g KS-6, 50g PVDF, and 900g NMP in a vacuum planetary mixer for 3 hours, then ground in a sand mill for 2 hours, and passed through a 200-mesh sieve to obtain an oily high-conductivity paste containing 5 wt% carbon. The morphology of the film formed by coating the highly conductive paste on the surface of aluminum foil is as follows: Figure 4 .

Embodiment 2

[0042] Take 30g of high-quality graphene powder (the average thickness is 3nm, the average sheet size is 20μm, and the average conductivity of the dry powder film is 10 5 S / m) and 10 g of 10,000-mesh graphite were stirred in ethanol and ultrasonicated for 1 h, and then dried at 80° C. to obtain graphene powder with carbon black adsorbed on the surface. The powder was stirred with 10g CNTs, 300g LA132 binder, and 650g water in a vacuum planetary mixer for 3 hours, then ground in a sand mill for 2 hours, and passed through a 200-mesh sieve to obtain an aqueous high-conductivity paste containing 5 wt% carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com