Anisotropic magnetoresistive permalloy buffer layer preparation method

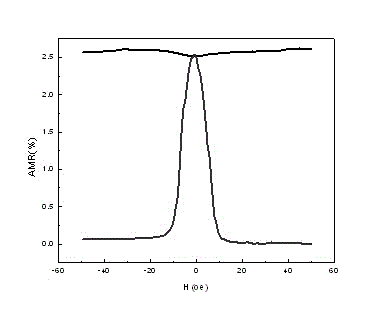

An anisotropic magnetic and permalloy technology, applied in metal material coating process, application of magnetic film to substrate, coating, etc., can solve the problem that the performance does not meet the requirements of use, the film AMR is small, and the coercive force It can reduce the coercivity, increase the AMR value, and increase the grain size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

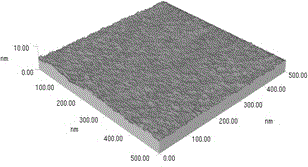

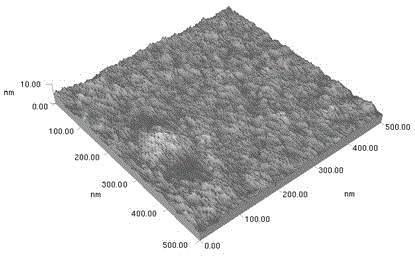

[0024] When implementing the preparation method of a kind of anisotropic magnetoresistive permalloy buffer layer of the present invention, as attached Figure 5 with 6 As shown, the method is implemented on the basis of the existing substrate, that is, the buffer layer is first deposited on the existing substrate, then the NiFe layer is deposited, and finally the protective layer is covered. The process of depositing the buffer layer is adopted in The pulsed radio frequency is used as the sputtering power source at normal temperature, and the structure prepared by the invention is consistent with the traditional structure.

[0025] The specific production process is to put the cleaned substrate (using silicon wafer) into the vacuum chamber and evacuate it to 5x10-5Pa, and pass in argon gas throughout the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com