Carbon nanotube fiber array cold cathode preparation method

A technology of carbon nanotube fibers and aligned carbon nanotubes, which is applied in the field of preparation of cold cathodes of carbon nanotube fiber arrays, and can solve the problems of low performance of bulk materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

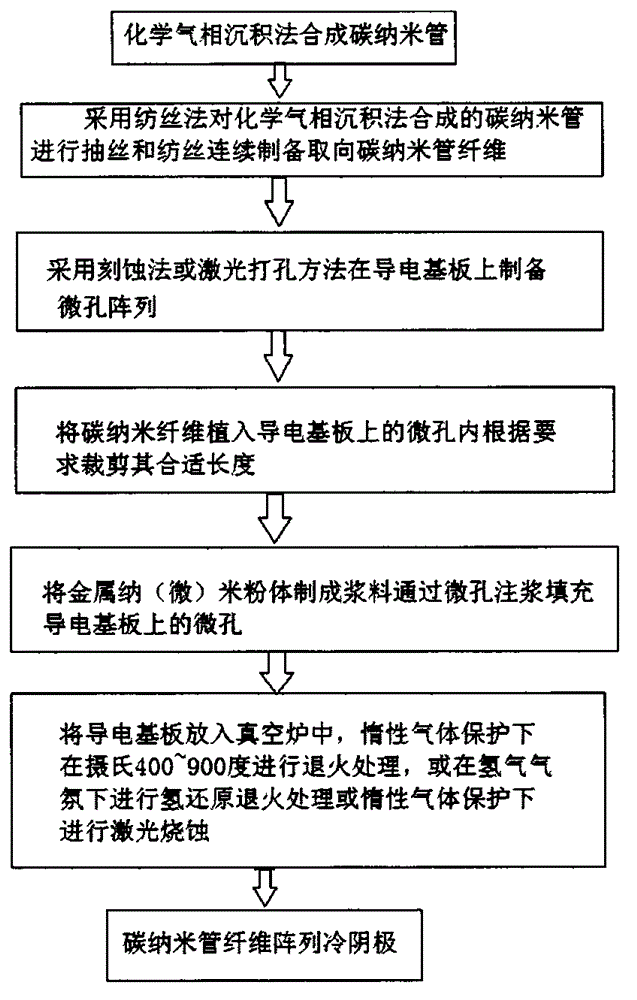

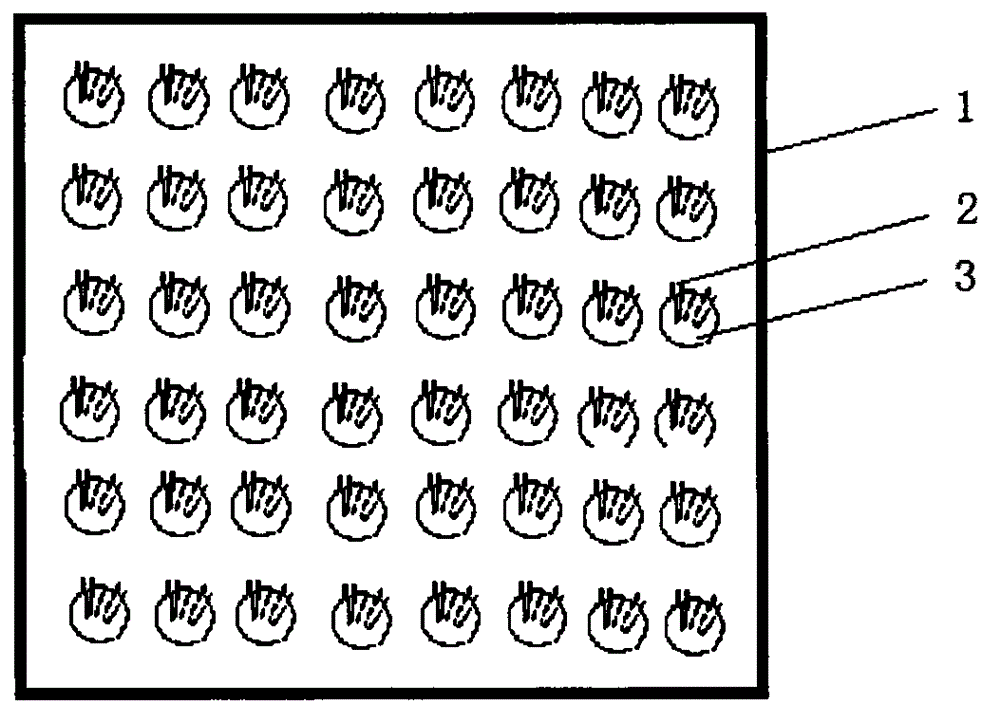

[0016] The invention discloses a method for preparing a carbon nanotube fiber array cold cathode, see figure 1 The method includes step 1, synthesizing ultra-long aligned carbon nanotubes on a silicon substrate deposited with multilayer metal catalysts by using a water-assisted chemical vapor deposition method. Step 2: Spinning and spinning the carbon nanotubes synthesized by water-assisted chemical vapor deposition by dry spinning method to continuously prepare aligned carbon nanotube fibers with a diameter of about 20 microns. Step 3: On the metal molybdenum substrate with a thickness of 0.5mm, the electron beam etches a microhole array with a diameter and a depth of 30-50 microns, and then implants the spun carbon nanotube fiber into the microhole array, and cuts the microhole array according to the appropriate requirements. 30-70 microns in length, see figure 2 . Step 4, the nanometer indium tin oxide powder is made into a slurry to fill the micropores on the conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com