Infrared detector array and manufacturing method thereof

A technology of infrared detectors and arrays, which is applied in semiconductor devices, final product manufacturing, radiation control devices, etc., can solve problems such as difficulty in realization and affecting the generation of photogenerated carriers, and achieve improved quantum efficiency, enhanced capabilities, and reduced The effect of crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

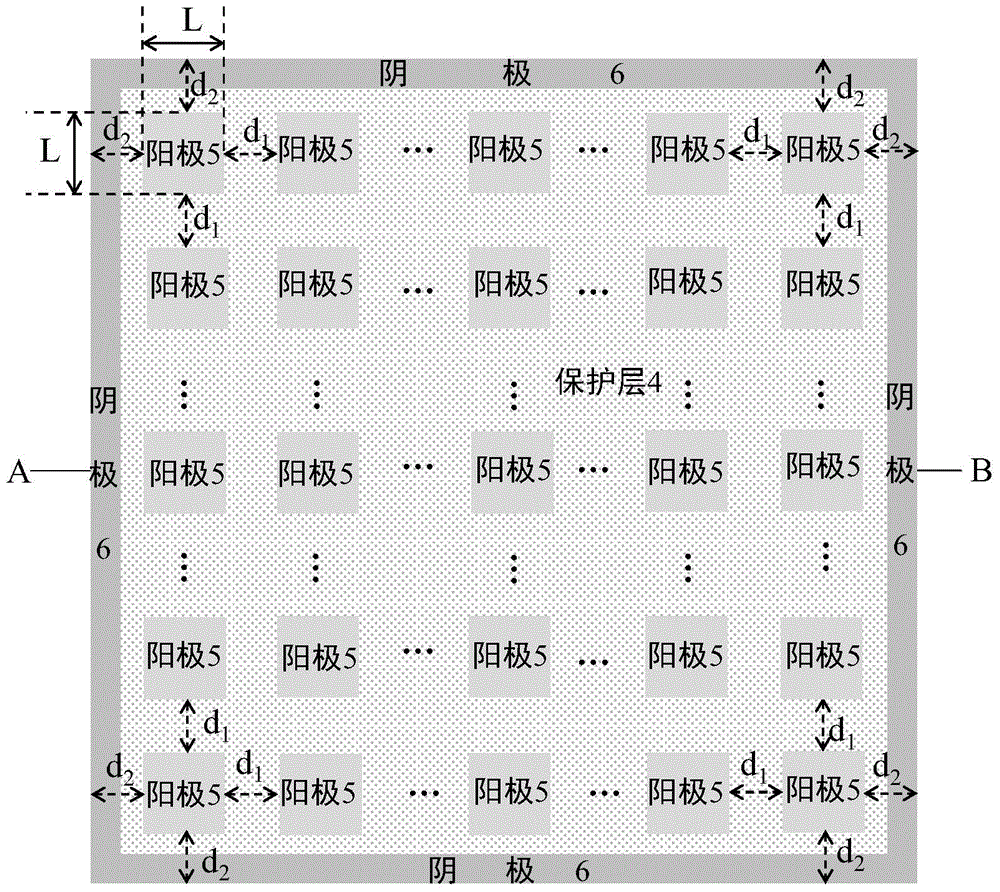

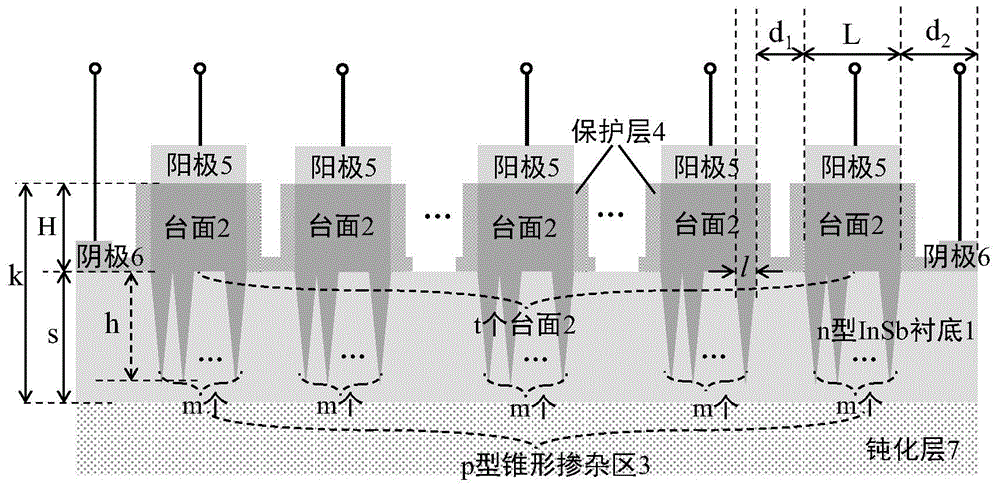

[0037] Embodiment 1: The protective layer is made of SiN, the passivation layer is made of SiN, the number of p-type conical doped regions directly below each mesa is m×m=4×4, and the array size is an infrared detector array of 30×30 .

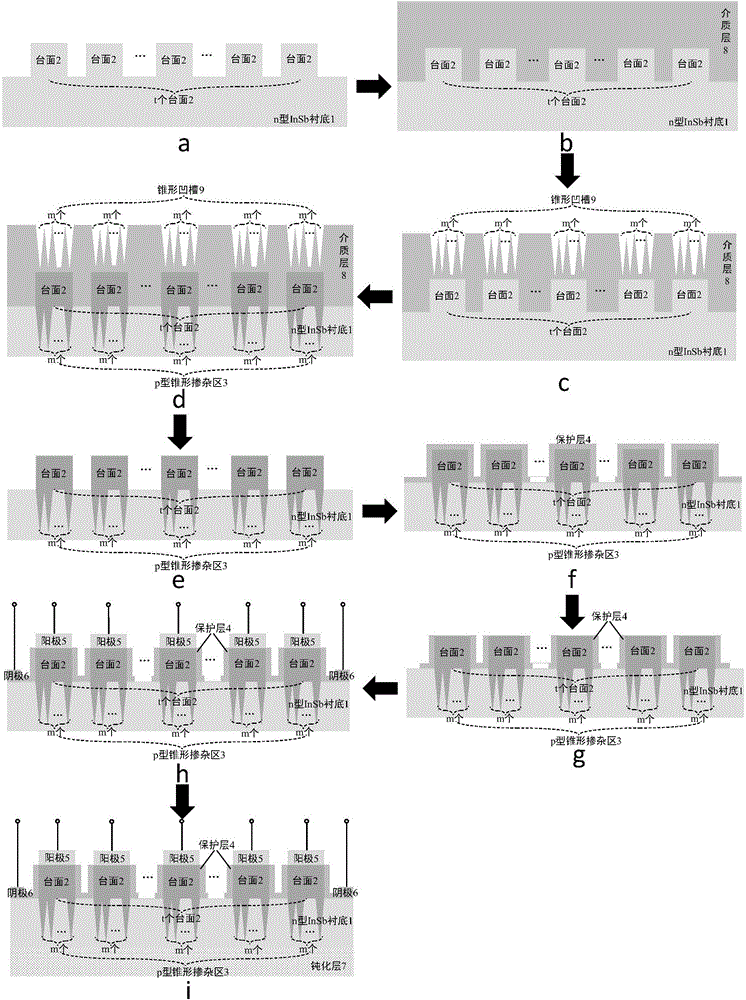

[0038] Step 1, etching and manufacturing 30×30 mesas 2 on the n-type InSb substrate 1, such as image 3 a.

[0039] 1a) At a thickness k of 21 μm and a doping concentration of 1×10 16 cm -3 For the first time, a mask is made on the n-type InSb substrate 1. The mask pattern is an array composed of 30×30 squares with a side length L of 56 μm, and the distance between two adjacent squares is d 1 , and the distance d between the most edge square and the edge of n-type InSb substrate 1 2 Both are 45μm;

[0040] 1b) Use the mask to etch 30×30 mesas 2 on the n-type InSb substrate 1 by reactive ion etching technology, where the height H of each mesa is 12 μm. After the n-type InSb substrate 1 is etched The thickness s is 9 μm. The process condi...

Embodiment 2

[0066] Embodiment 2: Making the protective layer is SiO 2 , the passivation layer is SiO 2 , the number of p-type tapered doped regions directly below each mesa is m×m=2×2, and the array size is an infrared detector array of 512×512.

[0067] Step 1, etching and manufacturing 512×512 mesas 2 on the n-type InSb substrate 1, such as image 3 a.

[0068]At a thickness k of 11 μm and a doping concentration of 1×10 14 cm -3 The n-type InSb substrate 1 made a mask for the first time, using inductively coupled plasma reactive etching technology, in Ar / CH 4 / H 2 Under the process conditions of flow ratio of 1:3:10, pressure of 10Pa, and power of 550W, 512×512 square mesas with height H of 6 μm and side length L of 36 μm were etched on n-type InSb substrate 1 2, where the distance d between two adjacent mesa 1 , the distance d between the edge of the mesa and the edge of the n-type InSb substrate 1 2 Both are 20 μm; the thickness s of the n-type InSb substrate 1 after etching i...

Embodiment 3

[0085] Embodiment three: making protective layer is SiN, and passivation layer is SiO 2 , the number of p-type tapered doped regions directly below each mesa is m×m=1×1, and the array size is an infrared detector array of 10000×10000.

[0086] Step A, etching and manufacturing 10000×10000 mesas 2 on the n-type InSb substrate 1, such as image 3 a.

[0087] At a thickness k of 2.6 μm and a doping concentration of 1×10 11 cm -3 Masks were fabricated on the n-type InSb substrate 1 for the first time, and 10,000×10,000 square mesas 2 with a side length of 8 μm were etched on the n-type InSb substrate 1 by inductively coupled plasma reactive etching technology. The distance d between two tables 1 , the distance d between the edge of the mesa 2 and the edge of the n-type InSb substrate 1 2 Both are 0.5 μm, and the height H of each mesa is 0.6 μm; the thickness s of the n-type InSb substrate 1 after etching is 2 μm. The process conditions used for etching the mesa are: Ar / CH 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com