Method for preparing high-aqueous-dispersion astaxanthin ester microspheres

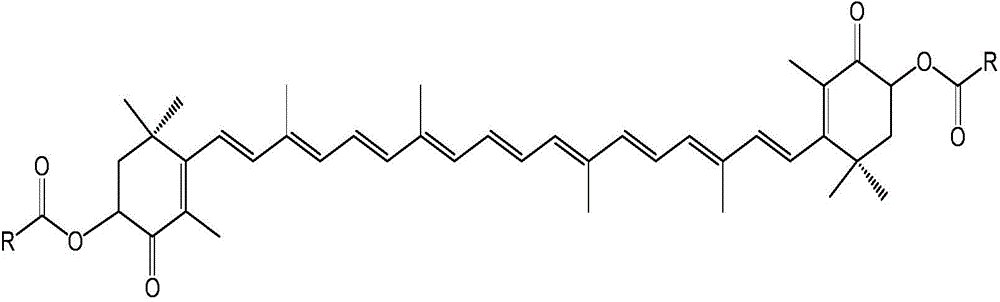

A technology of astaxanthin ester and microspheres, which is applied in the field of preparation of highly water-dispersible astaxanthin ester microspheres, can solve the problems of easy oxidation and degradation, poor water solubility of astaxanthin ester, etc., achieve high water dispersibility, and facilitate industrialization Promote and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

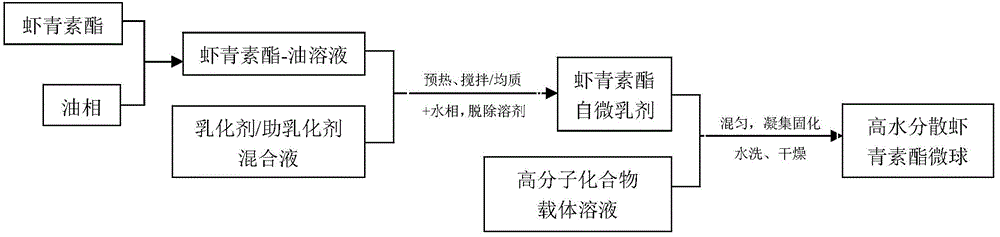

[0023] 1) Preparation of astaxanthin ester self-microemulsion

[0024] Dissolve astaxanthin ester in the oil phase at 10°C-80°C to make an oil solution of astaxanthin ester; agent and / or co-emulsifier, after homogenization, add the water phase, after homogenization, evaporate and remove the solvent under low temperature and low pressure conditions to prepare astaxanthin ester self-microemulsion;

[0025] 2) Preparation of high water dispersion astaxanthin ester microspheres

[0026] Add water to the polymer compound carrier to prepare a polymer compound carrier solution, then add the astaxanthin ester self-microemulsion prepared in step 1) at a volume ratio of 1:0.5-10, stir and mix well, and add the mixed liquid dropwise at a concentration of 0.2 ~3.0mol / L calcium chloride solution, stand at 2℃~10℃ for 10min~150min, let it coagulate and solidify, collect gel beads, wash and dry to make high water dispersible astaxanthin ester microspheres .

Embodiment 1

[0029] (1) Preparation of astaxanthin ester self-microemulsion

[0030] Weigh 1 kg of astaxanthin ester crude extract, and dissolve it with 3L ethyl acetate at room temperature to obtain astaxanthin ester-ethyl acetate solution; Solution 12L Tween 80 / absolute ethanol (2:1) mixture, stir or homogenize to make the system uniform; then add 10L water to the system, homogenize until the system is uniform, and then concentrate to the solid solvent with a rotary evaporator Flow out to obtain astaxanthin ester self-microemulsion.

[0031] (2) Preparation of highly water-dispersible astaxanthin ester microspheres

[0032] Prepare a sodium alginate solution with a concentration of 30g / L, and stir it at a temperature of 30°C to fully dissolve it to obtain a sodium alginate solution; then the astaxanthin ester obtained in step (1) is self-microemulsion and sodium alginate Mix the solution according to the volume ratio of 1:1, stir and mix well, drop the above mixed solution into 1mol / L ...

Embodiment 2

[0035] (1) Preparation of astaxanthin ester self-microemulsion

[0036] Weigh 1 kg of astaxanthin ester crude extract, and dissolve it with 3L ethyl oleate at room temperature to obtain astaxanthin ester-ethyl oleate solution; Ethyl acetate solution 12L Tween 80 / absolute ethanol (2:1) mixture, stir or homogenize to make the system uniform; then add 5L water to the system, homogenize until the system is uniform, and then concentrate with a rotary evaporator The solvent of the final product flows out to obtain astaxanthin ester self-microemulsion.

[0037] (2) Preparation of highly water-dispersible astaxanthin ester microspheres

[0038] Prepare a sodium alginate solution with a concentration of 30g / L, and stir it at a temperature of 30°C to fully dissolve it to obtain a sodium alginate solution; then the astaxanthin ester obtained in step (1) is self-microemulsion and sodium alginate Mix the solution according to the volume ratio of 1:0.8, stir and mix evenly, drop the above...

PUM

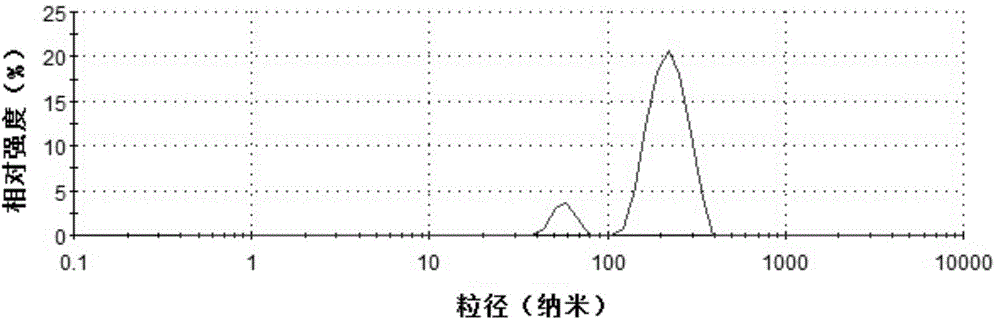

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com