Preparation method of clomiphene polymer capable of adsorbing heavy metal ions and application of clomiphene polymer

A phenolamine polymer, heavy metal ion technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants and other directions, can solve the problems of low active component content, limited adsorption capacity, low load capacity, etc. Strong adsorption capacity, mild reaction conditions, and solvent-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Preparation of phenolamine polymer

[0019] Dissolve catechol and hexamethylenediamine with a molar ratio of 1:1 in 50ml of distilled water at a concentration of 0.004mol / L, and set the reaction temperature in the electromagnetic force stirring oil bath to 30 o C, reacted for 48h, centrifuged, washed, 40 o C was dried in vacuum to obtain a phenolic amine polymer.

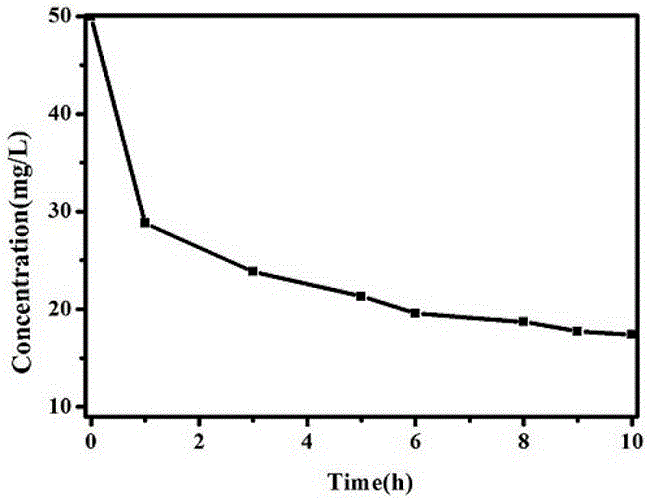

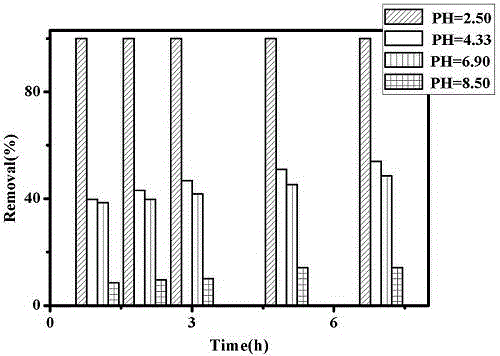

[0020] (2) Research on the effect of phenolic amine polymer on heavy metal ion Cr 6+ Adsorption performance

[0021] Disperse 200 mg of phenamine polymer into 30 mL of K 2 Cr 2 o 7 (100mg / L, pH=2.5) solution, stir with a magnetic stirrer, centrifuge once every hour, take 2ml of the supernatant and save it, pour the remaining solution in the centrifuge tube back into the original adsorption reaction solution to continue the adsorption reaction . After 6 to 13 hours, all the supernatants were prepared with diphenylcarbazide chromogen to form 53ml of purple-red solution, and the remaining Cr was detec...

Embodiment 2

[0024] (1) Preparation of phenolic amine polymer

[0025] Dissolve catechol and triethylenetetramine with a molar ratio of 1:1.2 in 50ml of distilled water, and set the reaction temperature in the electromagnetic stirring oil bath to 50 o C, react for 72 hours, centrifuge, wash, and dry at room temperature to obtain a phenolamine polymer.

[0026] (2) Research on the adsorption performance of phenolic amine polymers on heavy metal ion lead

[0027] The specific implementation method is the same as in Example 1, and now the lead ion solution pH=5. The results showed that the adsorption capacity of the phenolamine polymer was about 35 mg / g.

Embodiment 3

[0029] (1) Preparation of phenolic amine polymer

[0030] Dissolve catechol and hexamethylenediamine with a molar ratio of 1:0.9 in 50ml of distilled water, the concentrations are 0.0040mol / L and 0.0036mol / L respectively, set the reaction temperature in the electromagnetic stirring oil bath to 20°C , reacted for 72h, centrifuged, washed, and dried at 40°C to obtain a phenolic amine polymer.

[0031] (2) Research on the adsorption performance of phenolic amine polymers on heavy metal ions cadmium

[0032] The specific implementation method is the same as in Example 1, and now the pH=7.0 of the heavy metal solution. The results showed that the adsorption capacity of the phenolamine polymer was about 25 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com