Preparation method of TiO2 nanowire photocatalyst modified by Au nanoparticles

A photocatalyst and nanoparticle technology, applied in the field of photocatalyst preparation, can solve the problems of limited application, nano pollution, difficult recycling of catalysts, etc., and achieve the effects of improving utilization, avoiding pollution, and good reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A Au / TiO 2 The preparation method of nanowire photocatalyst, the steps are as follows:

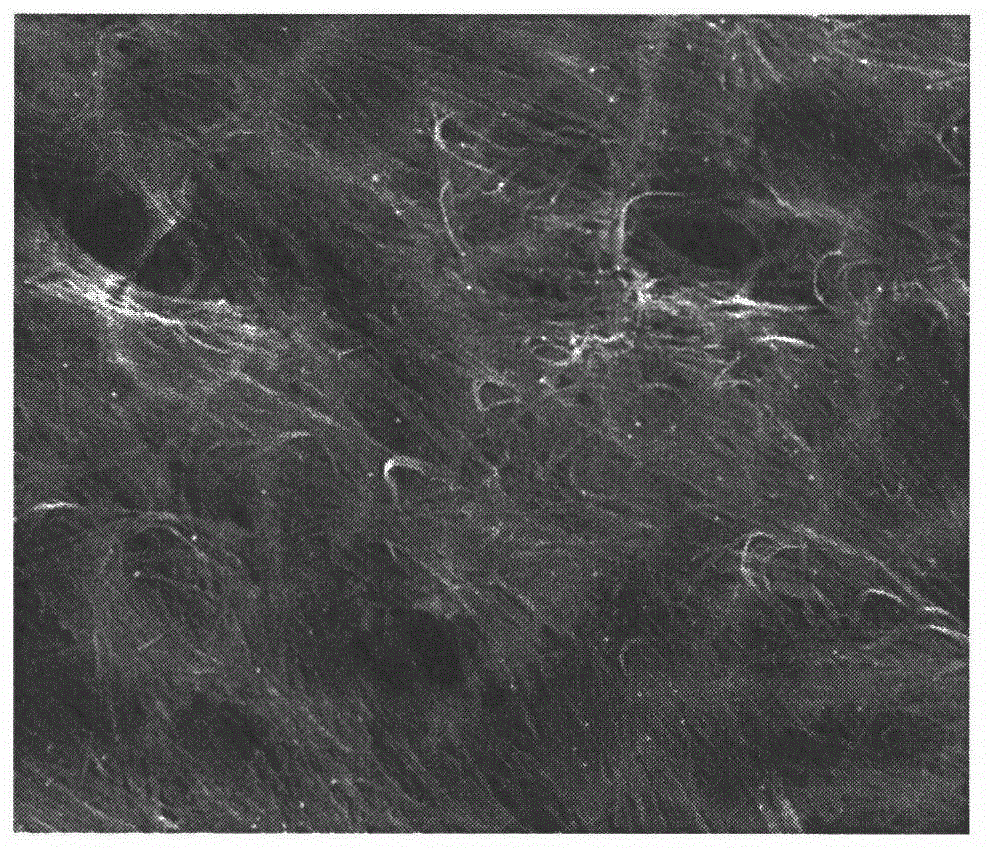

[0020] 1. TiO 2 Preparation of nanowires: Clean the titanium sheet with ethanol and pickle to remove the oil and oxide layer on the surface, then polish the surface of the titanium sheet with 1000-mesh sandpaper until the surface is uniform and smooth, and then oxidize it by anodic oxidation , the electrolyte is an ethylene glycol solution of water, the content of water is 3.5% (v / v), the content of ammonium fluoride is 0.4wt%, and the step-up method is adopted, and the boosting speed is 1 volt every 2 seconds , the highest voltage is 60V, the anodic oxidation treatment time is 2.5h, and after the oxidation treatment, it is calcined in the air at 450°C for 1h;

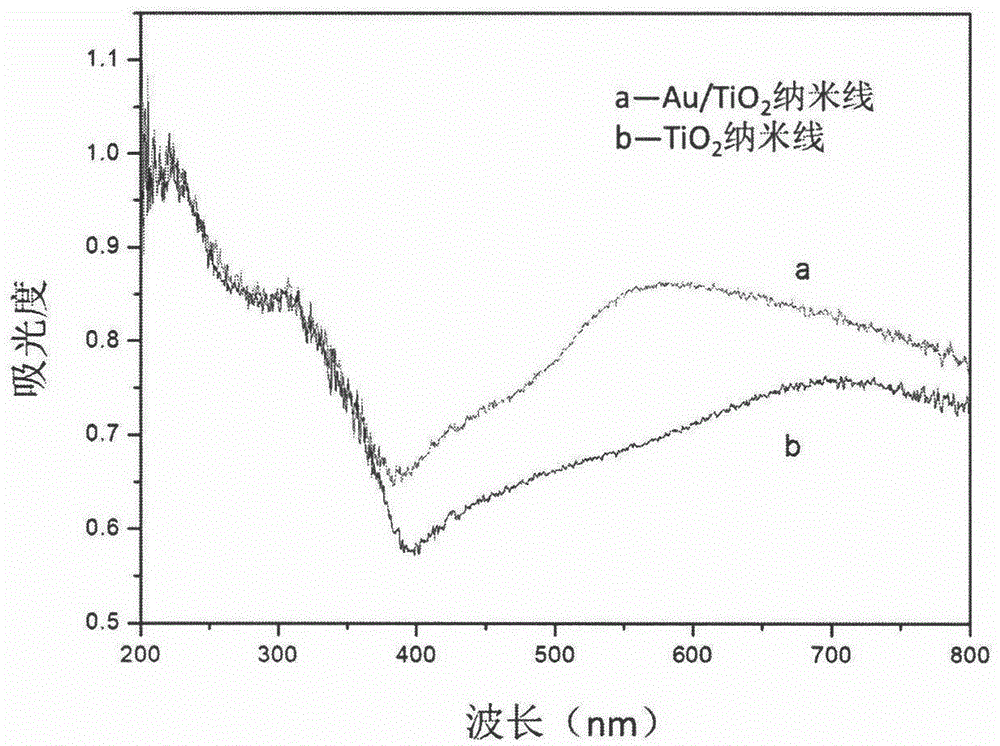

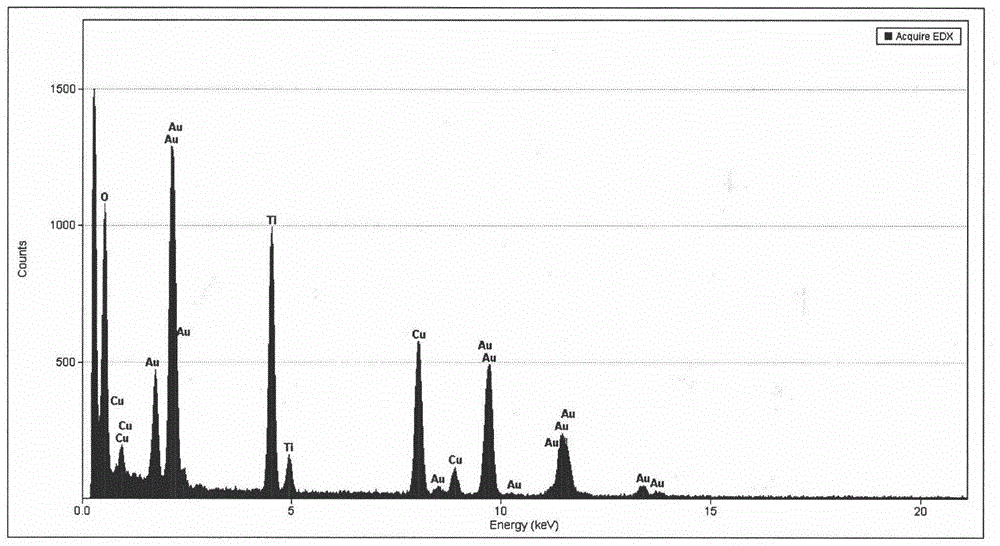

[0021] 2. Au nanoparticle modification: the adsorption-photoreduction method was used to treat TiO 2 The nanowires were modified with Au nanoparticles, and the gold source was chloroauric acid solution with a concentratio...

Embodiment 2

[0026] A Au / TiO 2 The preparation method of nanowire photocatalyst, the steps are as follows:

[0027] 1. TiO 2 Preparation of nanowires: Clean the titanium sheet with ethanol and pickle to remove the oil and oxide layer on the surface, then polish the surface of the titanium sheet with 1000-mesh sandpaper until the surface is uniform and smooth, and then oxidize it by anodic oxidation , the electrolyte is an ethylene glycol solution of water, the content of water is 4% (v / v), the content of ammonium fluoride is 0.45wt%, and the step-up method is adopted, and the boosting speed is 1 volt every 2 seconds , the highest voltage is 60V, the anodic oxidation treatment time is 2.5h, and after the oxidation treatment, it is calcined in the air at 450°C for 2h;

[0028] 2. Au nanoparticle modification: the adsorption-photoreduction method was used to treat TiO 2 The nanowires were modified with Au nanoparticles, and the gold source was chloroauric acid solution with a concentration...

Embodiment 3

[0033] Au / TiO 2 The preparation method of nanowire photocatalyst, the steps are as follows:

[0034] 1. TiO 2 Preparation of nanowires: Clean the titanium sheet with ethanol and pickle to remove the oil stain and oxide layer on the surface, then polish the surface of the titanium sheet with 1000-mesh sandpaper until the surface is uniform and smooth, and then oxidize it by anodic oxidation , the electrolyte is an ethylene glycol solution of water, the content of water is 4.5% (v / v), the content of ammonium fluoride is 0.5wt%, and the step-up method is adopted, and the boosting speed is 1 volt every 2 seconds , the highest voltage is 60V, the anodic oxidation treatment time is 2.5h, and after the oxidation treatment, it is calcined in the air at 490°C for 1h;

[0035] 2. Au nanoparticle modification: the adsorption-photoreduction method was used to treat TiO 2 The nanowires were modified with Au nanoparticles, and the gold source was chloroauric acid solution with a concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com