Copper-zinc-cerium-based catalyst for low-temperature deep removal of carbon monoxide and preparation method and application of catalyst

A cerium-based catalyst and carbon monoxide technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of unclear service life of adsorbed substances and no clear activation method To achieve the effect of improving the ability to capture or release surface lattice oxygen, improve the reduction and oxidation performance, and improve the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

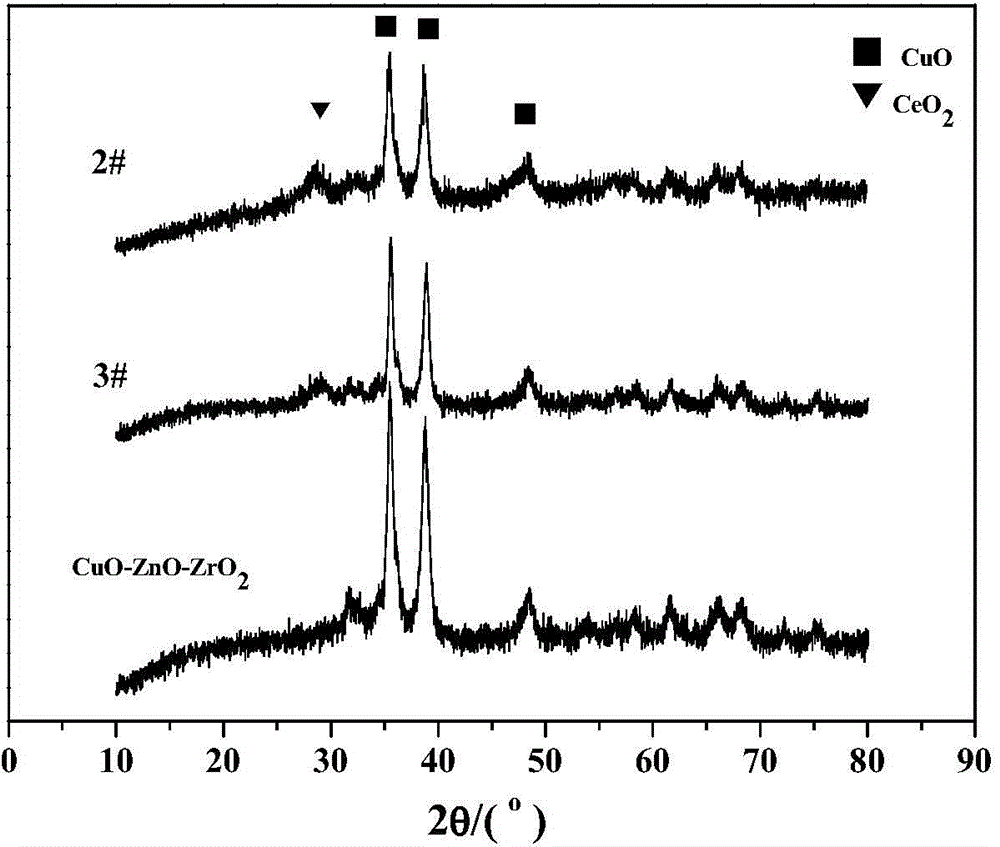

[0058] Preparation of CuZnCerium-Based Catalyst Precursor

[0059] Using different CuO:ZnO:CeO 2 Proportioning, raw materials are weighed, and the specific component contents are shown in Table 1 in terms of weight percentage.

[0060] After preparing the nitrate of Cu, Zn, Ce metal into a certain concentration of solution, mix well under full stirring; the molar ratio of nitrate solution and alkali solution is 1:1; Co-precipitate with alkali solution under stirring, the precipitation temperature is 60-80°C; after the precipitation is completed, adjust the pH value of the system to 6-7; age the obtained catalyst precursor at a certain temperature, and fully stir; take out the solid product, After repeated washing and centrifugation with deionized water at a certain temperature, place in a drying oven to dry at 100-120°C for 12 hours; roast at 350-550°C for 6.0 hours, and cool to room temperature to obtain the copper-zinc-cerium-based catalyst product;

Embodiment 2

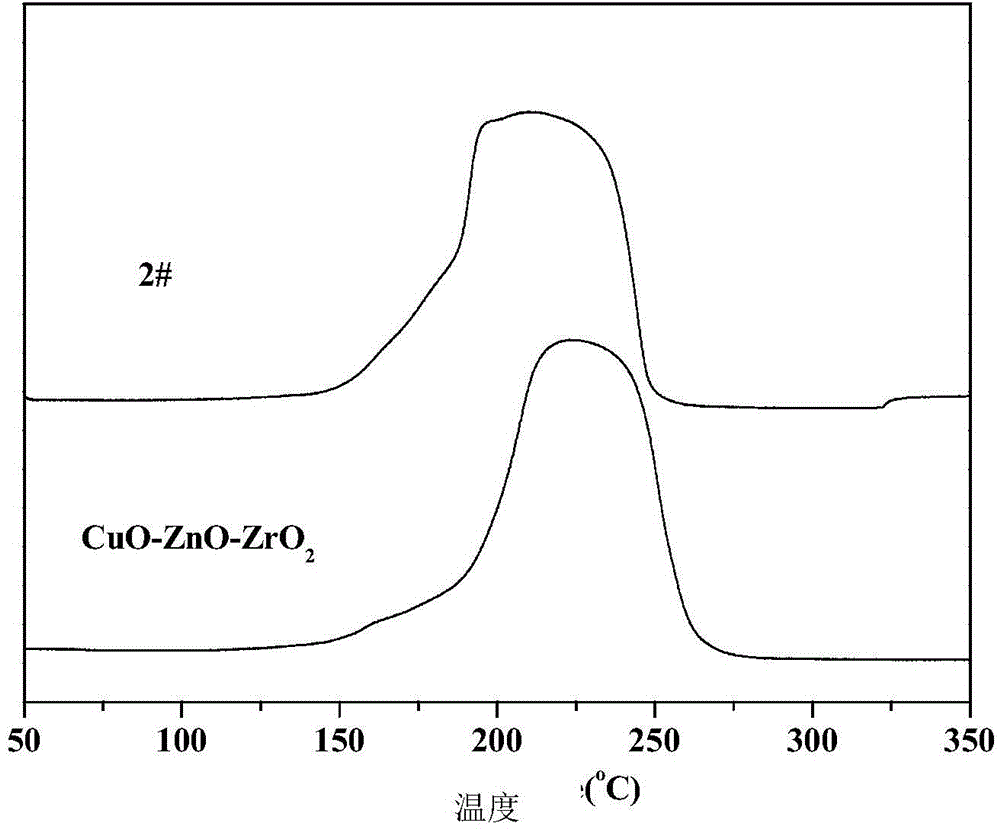

[0079] The activation of embodiment 2, embodiment 3 catalyst

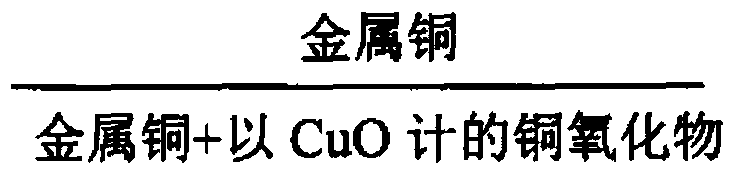

[0080] After granulating, tableting, and crushing the catalyst obtained in Implementation 2, select 60-80 mesh catalyst particles for activation. A stainless steel tube fixed bed reaction device was used for activation, and the catalyst prepared in Example 2 was reductively activated. The process conditions used for activation were: catalyst loading 3mL, temperature 120°C, normal pressure, activation time 2h, reducing gas 10 %H 2 / N 2 , the volume space velocity is 4000h -1 . A catalyst with a reduction degree of 77% was obtained, designated as Example 6.

Embodiment 3

[0081] The activation method of embodiment 3 catalyst is with embodiment 9, obtains catalyst, is marked as embodiment 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com