Wastewater treatment device and wastewater treatment method in sugar refining industry

A technology of industrial wastewater and treatment methods, which is applied in the direction of food industry wastewater treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of affecting the growth of activated sludge, difficult cultivation of granular sludge, and easy sludge bulking. , to extend the contact time, increase the speed and concentration, and achieve the effect of standard discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

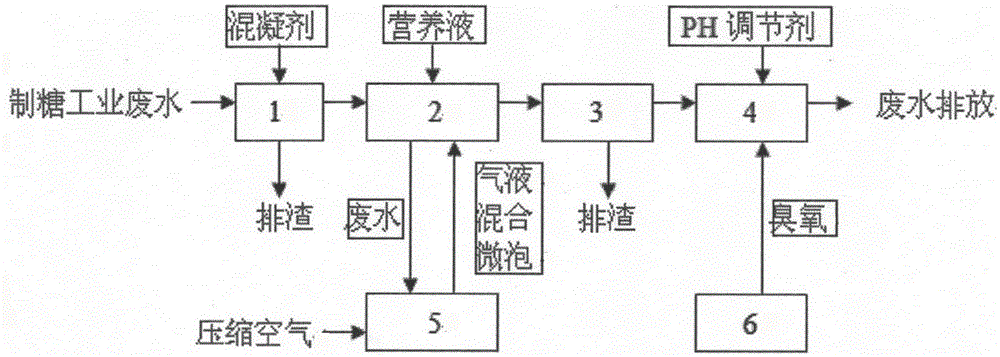

[0022] Such as figure 1 As shown, it is a schematic structural diagram of a refinery sugar industry wastewater treatment device. The refinery sugar industry wastewater treatment device includes a coagulation sedimentation tank 1, the outlet of the coagulation sedimentation tank 1 is connected to the water inlet of the SBR reaction tank 2, and the SBR reaction tank The water outlet of 2 is connected to the water inlet of sand filter 3, and the water outlet of sand filter 3 is connected to the water inlet of ozone reaction tank 4, wherein, described SBR reaction tank 2 is connected with aeration equipment, and described aeration equipment is A high-speed foaming machine 5, the ozone reaction tank 4 is connected to an ozone reactor 6.

[0023] The specific steps for using the above-mentioned refining sugar industrial wastewater treatment device to treat the refining sugar industrial wastewater are:

[0024] The first step: COD: 1000mg / L, SS: 500mg / L refined sugar industrial wast...

Embodiment 2

[0028] Such as figure 1As shown, it is a schematic structural diagram of a refinery sugar industry wastewater treatment device. The refinery sugar industry wastewater treatment device includes a coagulation sedimentation tank 1, the outlet of the coagulation sedimentation tank 1 is connected to the water inlet of the SBR reaction tank 2, and the SBR reaction tank The water outlet of 2 is connected to the water inlet of sand filter 3, and the water outlet of sand filter 3 is connected to the water inlet of ozone reaction tank 4, wherein, described SBR reaction tank 2 is connected with aeration equipment, and described aeration equipment is A high-speed foaming machine 5, the ozone reaction tank 4 is connected to an ozone reactor 6.

[0029] The specific steps for using the above-mentioned refining sugar industrial wastewater treatment device to treat the refining sugar industrial wastewater are:

[0030] The first step: COD: 400mg / L, SS: 200mg / L refined sugar industrial wastew...

Embodiment 3

[0034] Such as figure 1 As shown, it is a schematic structural diagram of a refinery sugar industry wastewater treatment device. The refinery sugar industry wastewater treatment device includes a coagulation sedimentation tank 1, the outlet of the coagulation sedimentation tank 1 is connected to the water inlet of the SBR reaction tank 2, and the SBR reaction tank The water outlet of 2 is connected to the water inlet of sand filter 3, and the water outlet of sand filter 3 is connected to the water inlet of ozone reaction tank 4, wherein, described SBR reaction tank 2 is connected with aeration equipment, and described aeration equipment is A high-speed foaming machine 5, the ozone reaction tank 4 is connected to an ozone reactor 6.

[0035] The specific steps for using the above-mentioned refining sugar industrial wastewater treatment device to treat the refining sugar industrial wastewater are:

[0036] The first step: COD: 800mg / L, SS: 400mg / L refined sugar industrial waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com