Method for preparing diphenyl ketone employing biomimetic catalysis of diphenylmethane and oxygen oxidation

A technology for biomimetic catalysis of diphenylmethane and oxygen oxidation. It is applied in the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds. It can solve problems such as the difficulty of benzophenone and the large steric hindrance of diphenylmethane. , to achieve the effect of high product selectivity, reduced energy consumption, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

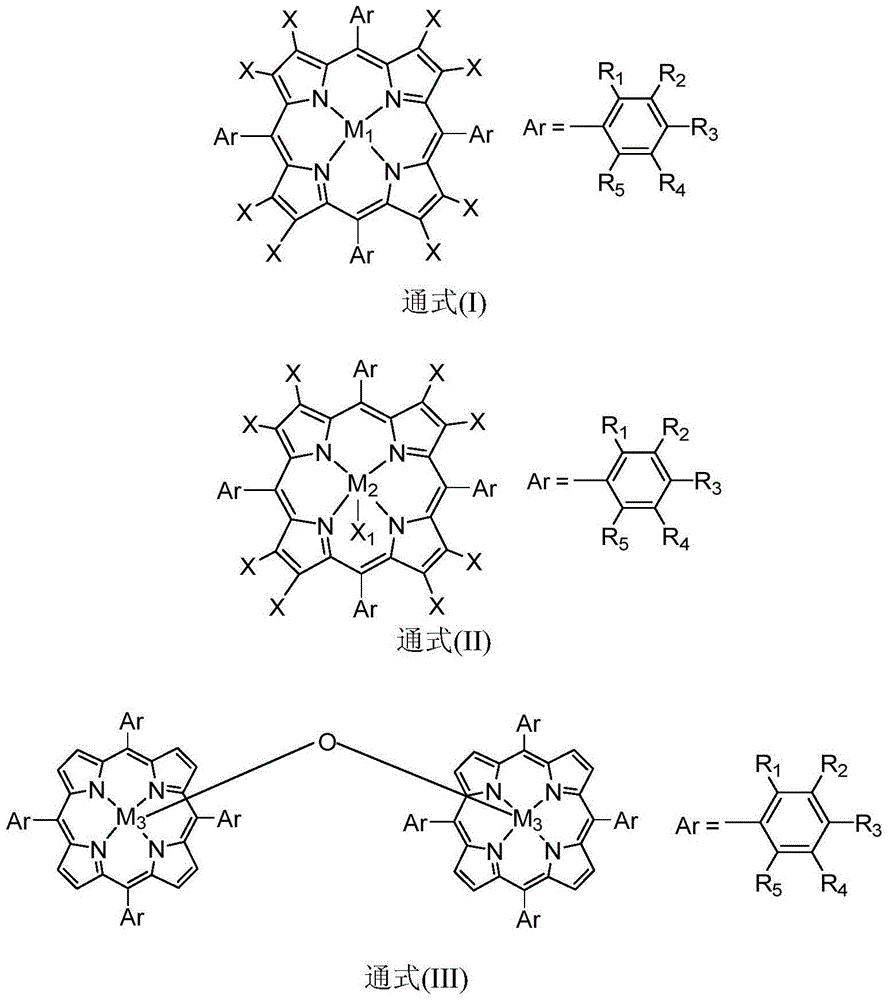

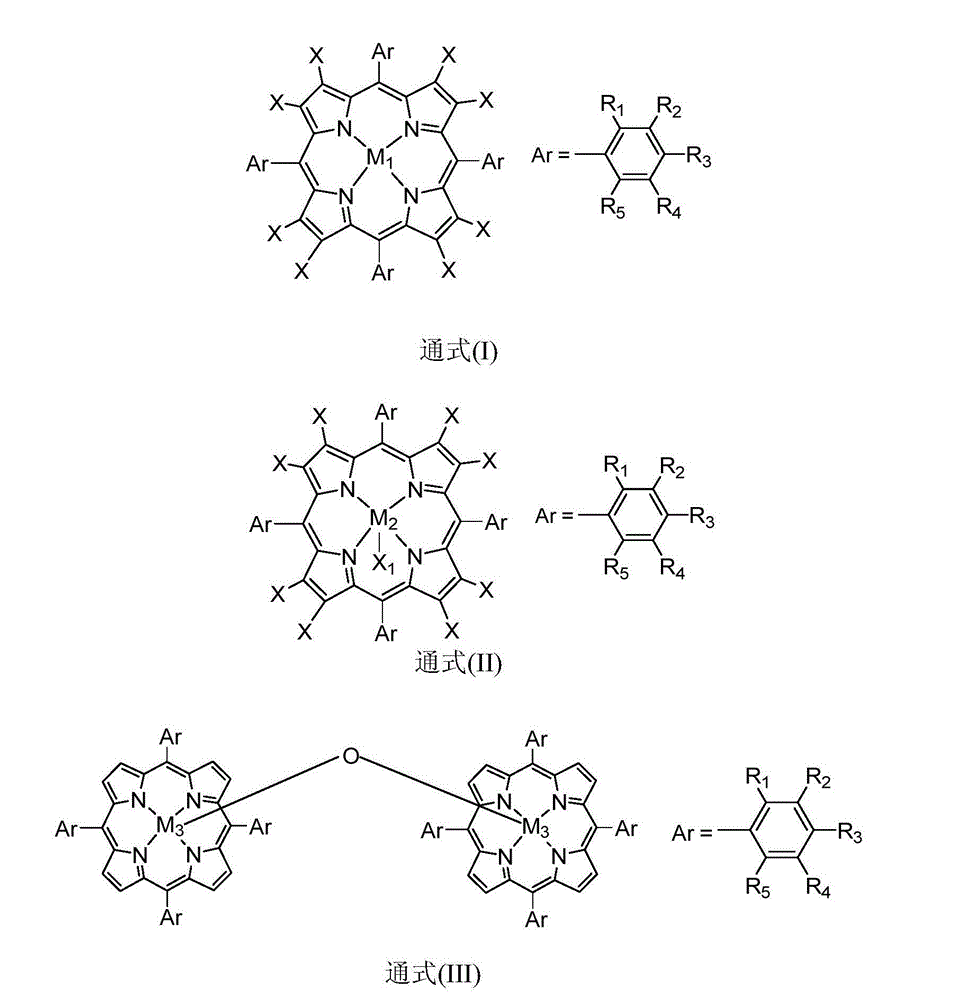

[0021] Containing 5ppm metalloporphyrin (M) with general formula (I) structure in 5mL 1 =Mn,X=H,R 1 = R 2 = R 3 = R 4 = R 5 =H) in the n-hexane solution, add 2mmol of diphenylmethane and 0.1mmol of cyclohexene, and fill with 2.0MPa of oxygen, and stir the reaction at a temperature of 50°C. After detection and analysis, the conversion rate of diphenylmethane is 22%, the selectivity of benzophenone is greater than 99%.

Embodiment 2

[0023] Containing 50ppm metalloporphyrin (M) with general formula (I) structure in 5mL 1 =Zn,X=H,R 1 = NO 2 , R 2 = R 3 = R 4 = R 5 =H) in the acetonitrile solution, add 2mmol of diphenylmethane and 1mmol of 2-methylcyclohexene, and fill with 0.2MPa of oxygen, and stir the reaction at a temperature of 100°C. After detection and analysis, the conversion of diphenylmethane The rate is 26%, and the selectivity of benzophenone is greater than 99%.

Embodiment 3

[0025] Containing 100ppm metalloporphyrin (M) with general formula (I) structure in 5mL 1 =Mg,X=H,R 3 =Cl,R 1 = R 3 = R 4 = R 5 =H) in the ethyl acetate solution, add 2mmol of diphenylmethane and 2mmol of 3-methylcyclohexene, and fill with 1MPa of oxygen, and stir the reaction at a temperature of 120°C. After detection and analysis, the content of diphenylmethane The conversion rate was 32%, and the selectivity to benzophenone was greater than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com