Rare earth doped alloy oxide luminescent coating and preparation method thereof

A luminescent coating, rare earth doping technology, applied in metal material coating process, coating, vacuum evaporation plating and other directions, can solve the problems of high film adhesion and high production cost, achieve firm bonding, improve production efficiency, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

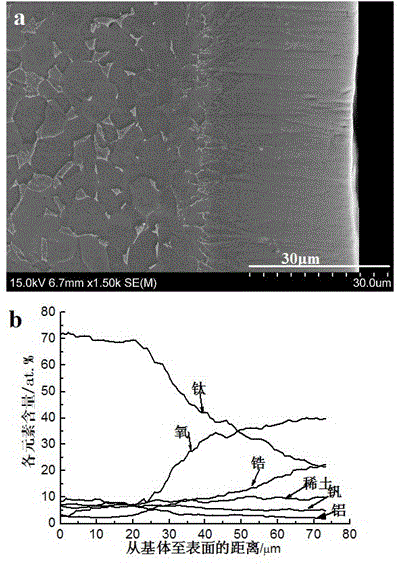

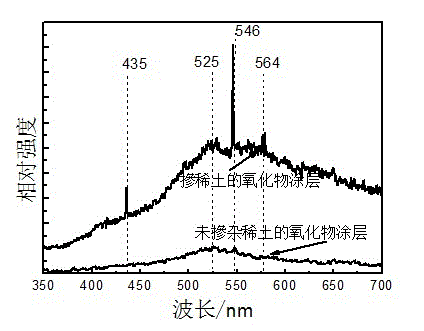

Image

Examples

Embodiment 1

[0031] The preparation method of zirconium-erbium-titanium alloy oxide luminous coating, the steps are as follows:

[0032] The first stage is the preprocessing stage, including the following steps:

[0033] (1) The metal surface is roughly ground and finely ground with 200#, 400#, 600#, 800# and 1000# sandpaper, and then polished with diamond abrasive paste, followed by ultrasonic cleaning with acetone; the pretreated The metal sample is placed on the base plate as the workpiece and protected by a heat preservation cover;

[0034] (2) The metal and rare earth targets are made into a grid structure, wherein the metal and rare earth targets are processed lath structures, and the shape is composed of a strip plate with a length of 130 mm, a width of 10 mm, and a thickness of 3 mm. A hole is drilled on both sides of each slat for hanging the target, wherein the distance between metal and rare earth grid slats is 6 mm, the ratio of metal to rare earth grid slats is 4:1, and the g...

Embodiment 2

[0050] A preparation method of zirconium-samarium-titanium alloy oxide luminescent coating, the steps are as follows:

[0051] The first stage is the preprocessing stage, including the following steps:

[0052] (1) The metal surface is roughly ground and finely ground with 200#, 400#, 600#, 800# and 1000# sandpaper, and then polished with diamond abrasive paste, followed by ultrasonic cleaning with acetone; the pretreated The metal sample is placed on the base plate as the workpiece and protected by a heat preservation cover;

[0053] (2) The metal and rare earth targets are made into a grid structure, wherein the metal and rare earth targets are processed lath structures, and the shape is composed of a strip plate with a length of 130 mm, a width of 10 mm, and a thickness of 3 mm. A hole is drilled on both sides of each slat for hanging the target, wherein the distance between metal and rare earth grid slats is 6 mm, the ratio of metal to rare earth grid slats is 3:1, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com