Magnetic nano composite capable of absorbing perfluorochemicals and preparation method thereof

A perfluorinated compound, magnetic nanotechnology, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc. problem, to achieve the effect of fast surface adsorption kinetic characteristics, simple and fast method, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

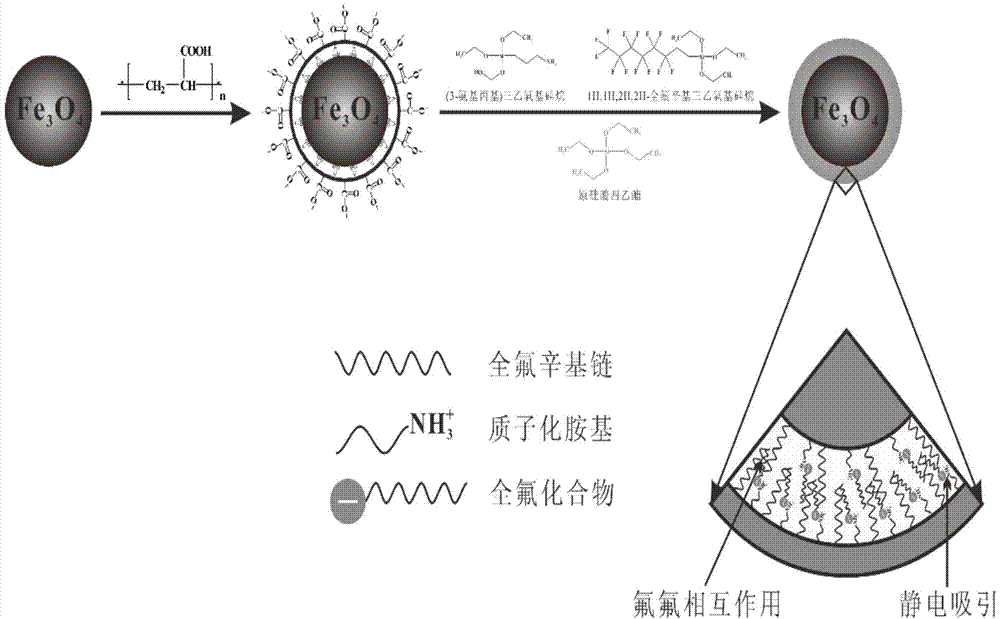

[0021] Preparation of High Adsorption Capacity Magnetic Nanocomposites for Selective Recognition of Perfluorinated Compounds

[0022] (1) Hydrophilic groups on the surface of magnetic nanoparticles: specific preparation steps: Fe 3 o 4 Nanoparticles are added to 0.2-0.4mol / L polyacrylic acid aqueous solution, the initial concentration of nanoparticles is 4-12g / L, continuous stirring and ultrasonication for 30-60min at 25-40°C, and repeated washing of the product with deionized water to remove unbound Polyacrylic acid can be dried in vacuum for 12-24 hours to obtain hydrophilic Fe 3 o 4 nanoparticles.

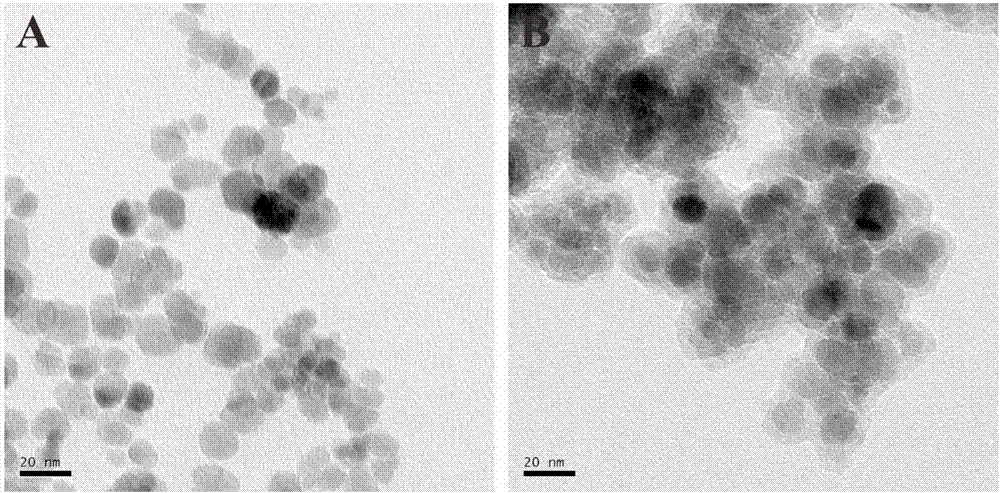

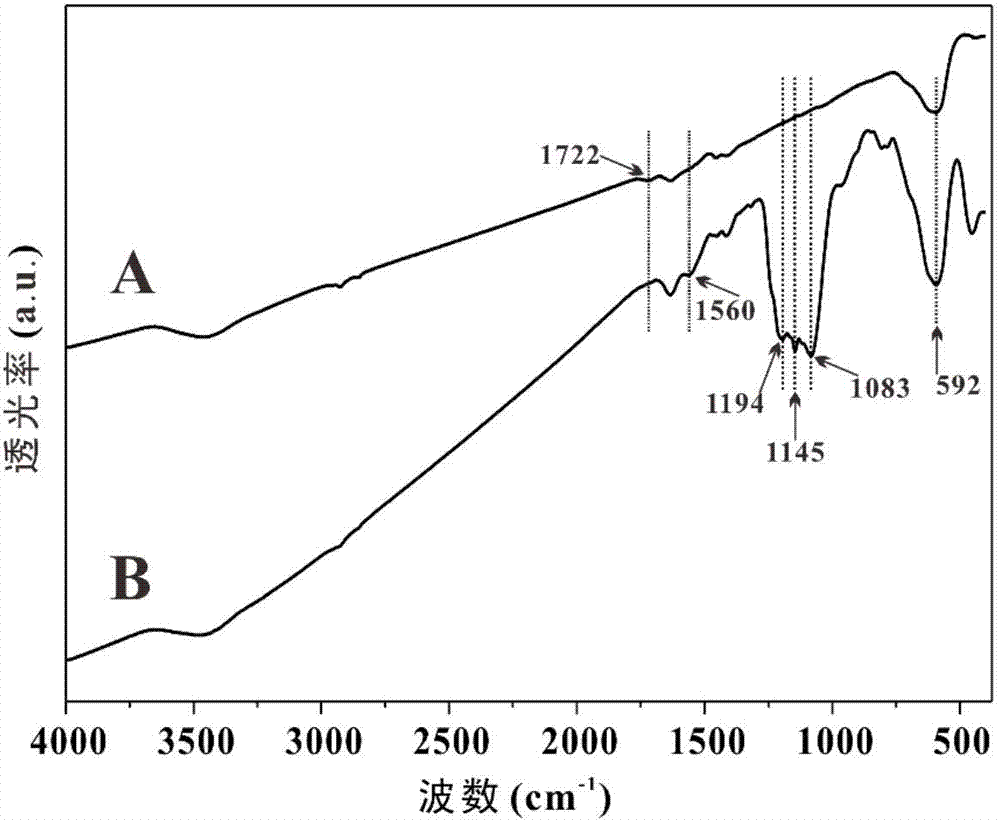

[0023] Depend on figure 2 (A) It can be seen that the morphology of each magnetic nanoparticle is clearly visible, the particle size is between 10-20nm, and there is no or little overlap between the particles. Therefore, the modification of the hydrophilic group effectively avoids the easy aggregation of the nanoparticles. shortcoming. image 3 (A)1722cm -1 shows an obvi...

Embodiment 2

[0031] 0.4g Fe 3 o 4 Nanoparticles were added to 100mL 0.2mol / L polyacrylic acid aqueous solution, continuously stirred and ultrasonicated for 30min at 30°C, the resulting product was repeatedly washed with deionized water to remove unbound polyacrylic acid, and vacuum dried for 12h to obtain Fe with hydrophilic activity. 3 o 4 nanoparticles. Mix 0.1 mmol (3-aminopropyl) triethoxysilane, 0.1 mmol 1H, 1H, 2H, 2H-perfluorooctyl triethoxysilane and 0.8 mmol tetraethyl orthosilicate as a precursor solution, add to 100mL 2g / L hydrophilic Fe 3 o 4 In the nanoparticle ethanol / water (3:1, v / v) dispersion system, add 1mL ammonia solution to the reaction system at the same time, continue to stir gently at 30°C for 6h, and mix ethanol / water (1:1, v / v) The solution repeatedly washes the product to remove unreacted chemicals, and vacuum-dries for 12 hours to obtain a high-adsorption-capacity magnetic nanocomposite material that selectively recognizes perfluorinated compounds.

Embodiment 3

[0033] 0.8g Fe 3 o 4 Nanoparticles were added to 100mL 0.3mol / L polyacrylic acid aqueous solution, continuously stirred and ultrasonicated for 45min at 30°C, the resulting product was repeatedly washed with deionized water to remove unbound polyacrylic acid, and vacuum dried for 12h to obtain Fe with hydrophilic activity. 3 o 4 nanoparticles. Mix 0.15 mmol (3-aminopropyl) triethoxysilane, 0.15 mmol 1H, 1H, 2H, 2H-perfluorooctyl triethoxysilane and 1.5 mmol tetraethyl orthosilicate as a precursor solution, add to 100mL 4g / L hydrophilic Fe 3 o 4 In the nanoparticle ethanol / water (3:1, v / v) dispersion system, add 1.25mL ammonia solution to the reaction system at the same time, keep stirring gently at 30°C for 9h, ethanol / water (1:1, v / v) The mixed solution repeatedly washes the product to remove unreacted chemicals, and vacuum-dries for 12 hours to obtain a magnetic nanocomposite material with high adsorption capacity that selectively recognizes perfluorinated compounds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com