Process for processing surface plasmon polariton coupled nano array based on scallop effect

A surface plasmon and nanoarray technology, applied in the field of plasmonic coupled nanoarrays, can solve the problems of poor controllability and limited practicality, and achieve the effect of optimizing the design of the coupling structure and facilitating process integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

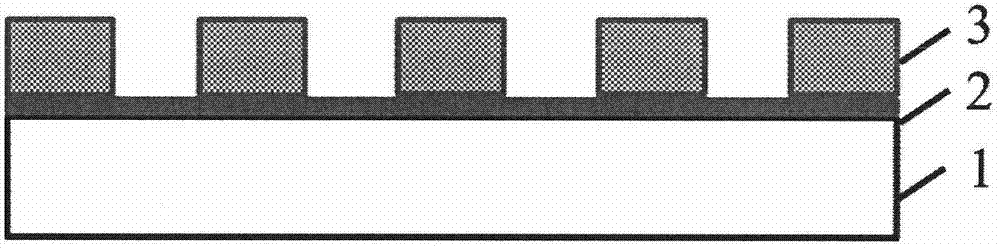

[0023] The present invention utilizes deep reactive ion etching of traditional microelectronics technology (formation of scallop topography sidewall by alternating etching and passivation——Scallop effect) and electron beam exposure (for making photolithography mask with nanoscale precision) technology , proposed a three-dimensional nano-optical structure processing technology combining electron beam exposure and deep reactive ion etching, and prepared functional units of "metallized nanostructure-spacer layer-metal film" and their periodic arrangement of "LSP-SPP coupling "Nanoarrays.

[0024] The principle of the "LSP-SPP coupling" nano-array processing technology of the present invention is as follows:

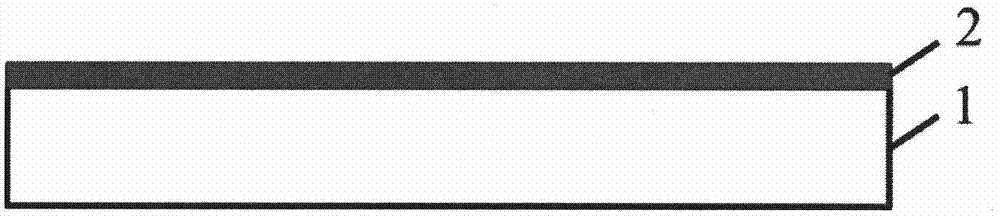

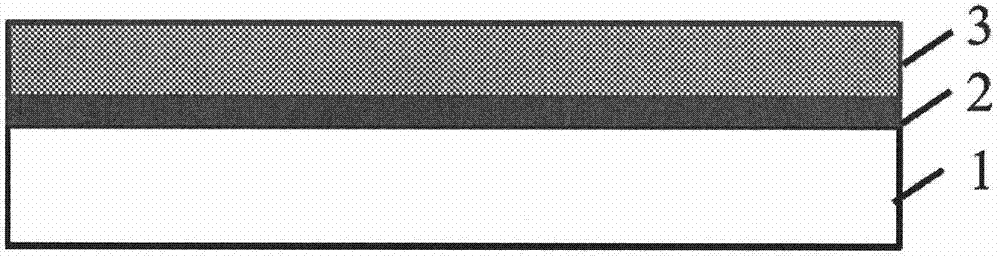

[0025] Such as Figure 1-7 As shown, an etch mask layer 2 is deposited on a substrate 1 (such as a silicon wafer) such as figure 1 , spin-coated e-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com