Recovery processing method of ammonia-nitrogen wastewater generated from nitric acid/ammonium nitrate production process

A technology for recycling and processing ammonia nitrogen wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, nitric acid, etc. It can solve the problems of secondary pollution, high energy consumption, large investment, etc., and achieve economical pollution control. Investment cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

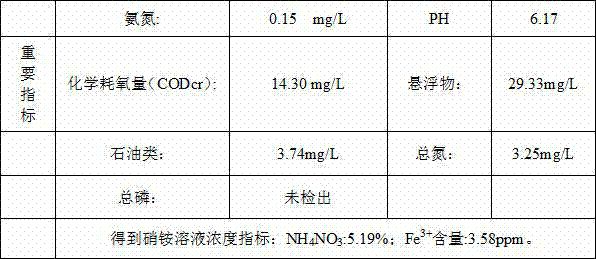

[0027] The amount of wastewater discharged in a nitric acid and ammonium nitrate production process is 22 tons / hour, the content of nitric acid is 5%, and the content of nitrate nitrogen is 871ppm.

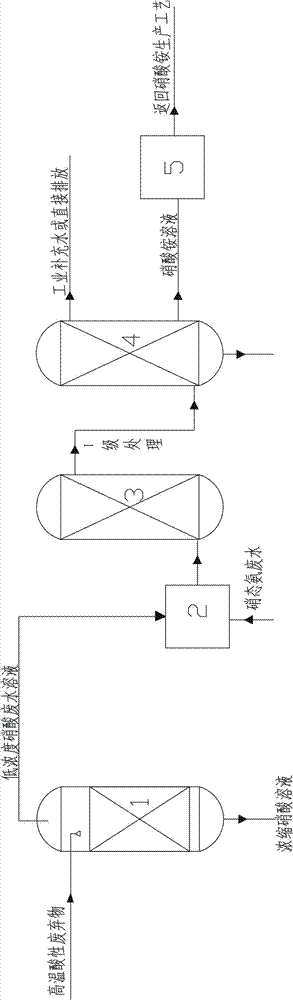

[0028] (1) if figure 1 As shown, the high-temperature acidic waste discharged from the nitric acid production process (the temperature of the high-temperature acidic waste entering the rectification tower inlet is 165°C, and the concentration of nitric acid is 5%) is introduced into the rectification tower 1 through pipelines, and the high-temperature acidic waste is used to Nitric acid is separated from the volatilization difference between nitric acid vapor and water vapor in the waste, that is, low-concentration nitric acid wastewater solution is discharged from the top of rectification tower 1; concentrated nitric acid solution (also known as tower tail water) is discharged from the bottom of rectification tower 1, and the concentrated nitric acid The solution is returned to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com