Heat pump evaporation process for recycling flue gas cleaning byproducts

A flue gas purification and heat pump evaporation technology, applied in the field of flue gas purification, can solve the problem that secondary steam cannot be used directly, and achieve the effects of light weight, continuous exhaust and consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

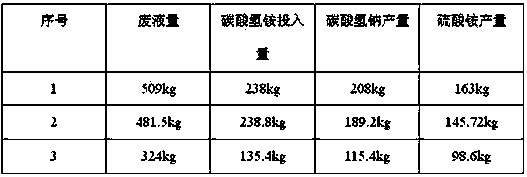

Embodiment 1

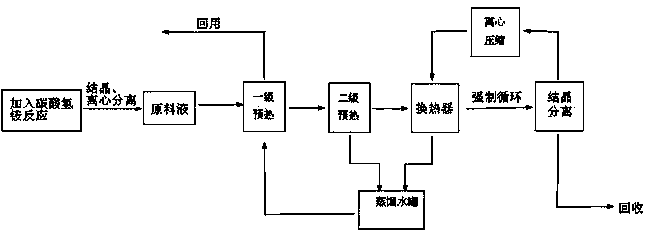

[0049] A heat pump evaporation process for recycling flue gas purification by-products. The waste liquid after wet purification of flue gas enters the reactor and reacts with ammonium bicarbonate. After the reaction is completed, the material liquid is separated from solid and liquid, and the liquid is cooled and crystallized. The clear liquid is used as the raw material liquid, pumped into the preheater, the preheated raw material liquid enters the heat exchanger, and is heated by the shell side steam in the tube side of the heat exchanger, and the temperature rises, and the raw material liquid enters under the push of the forced circulation pump Crystallization separator, flash evaporation occurs in the crystallization separator, the raw material liquid is supersaturated and crystallized, and ammonium salt crystals are obtained for recycling; the secondary steam generated by the flash evaporation is compressed by the compressor and enters the shell of the heat exchanger as a h...

Embodiment 2

[0051] This embodiment is basically the same as Embodiment 1, on this basis:

[0052] The solid obtained from the reaction of the waste liquid and ammonium bicarbonate is used as an absorbent and reused in the flue gas purification section.

Embodiment 3

[0054] This embodiment is basically the same as Embodiment 2, on this basis:

[0055] The compressor is a centrifugal compressor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com