Triazole-copper perchlorate complex with p-fluorophenylboronic acid catalyzing effect and preparation method of triazole-copper perchlorate complex

A technology of copper complexes and m-benzenebistriazole copper, which is applied in the direction of copper organic compounds, organic compounds/hydrides/coordination complex catalysts, chemical instruments and methods, etc., can solve the problems of expensive palladium catalysts and achieve reaction The effect of simple operation, high purity and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of 4-(3-(4H-1,2,4-triazol-4-yl)phenyl)-4H-1,2,4-triazole (L) Ligand

[0029] Add m-phenylenediamine (1 mmol) and bisformylhydrazide (2 mmol) respectively into a 50 mL three-neck round-bottom flask equipped with a magnet, reflux condenser and thermometer, and start stirring at 100 ° C for 12 hours. After the reaction was completed, the reaction solution was cooled to room temperature, and a large amount of precipitate was precipitated, which was recrystallized with water and ethanol, and the yield was 86%. Elemental Analysis C 10 h 8 N 6 Theoretical: C, 56.60; H, 3.80; N, 39.60. Experimental values: C, 56.56; H, 3.75; N, 39.56. The molar ratio of m-phenylenediamine and bisformylhydrazide is 1:2.

Embodiment 2

[0031] Cu(ClO 4 ) 2 and 4-(3-(4H-1,2,4-triazol-4-yl)phenyl)-4H-1,2,4-triazole) (L) in a molar ratio of 1:1;

[0032] L (0.0424 g, 0.2 mmol), Cu(ClO 4 ) 2 (0.0691 g, 0.2 mmol), H 2O (6 mL), CH 3 CN (4 mL), water hot 100 o After three days in C, it was slowly lowered to room temperature. After opening the kettle, there are yellow rod-shaped crystals suitable for X-ray single crystal diffraction analysis. Yield: 35% (calculated based on L). Elemental analysis (C 10 h 8.5 ClCuN 6 o 4.25 ) Theoretical value (%): C, 30.67; H, 2.03; N, 19.51. Found: C, 30.63; H, 2.06; N, 19.59. We also tried other ratios such as Cu(ClO 4 ) 2 If the molar ratio to L is 2:1, no crystalline compound can be obtained no matter how long the hydrothermal reaction time is. Therefore Cu(ClO 4 ) 2 The molar ratio of L and L is 1:1 is the best reaction ratio.

Embodiment 3

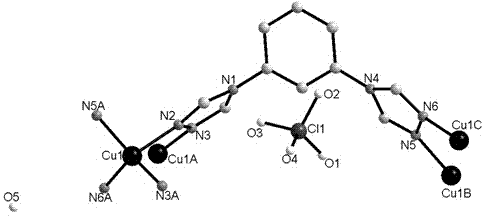

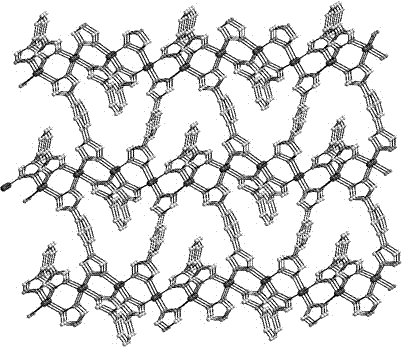

[0034] The crystal structure was determined using an APEX II CCD single crystal diffractometer, using graphite monochromatized Mokα rays (λ = 0.71073 ?) as the incident radiation. ω -2 θ Diffraction points are collected by scanning, and the unit cell parameters are obtained by least square method correction. The crystal structure is solved by software from the difference Fourier electron density map, and corrected by Lorentz and polarization effects. All H atoms were synthesized by difference Fourier transform and determined by ideal position calculation. The detailed crystal determination data are shown in Table 1. Structural primitives see figure 1 , the three-dimensional structure of the complex see figure 2 .

[0035] Table 1 Complexes 1 The crystallographic data of

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com