A heat pipe heating oil shale dry distillation gas process

A gas and oil shale technology, applied in the field of dry distillation of oil shale gas heat carrier, can solve problems such as carbon deposits blocking pipelines, and achieve the effects of easy operation, low failure rate, and reasonable process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

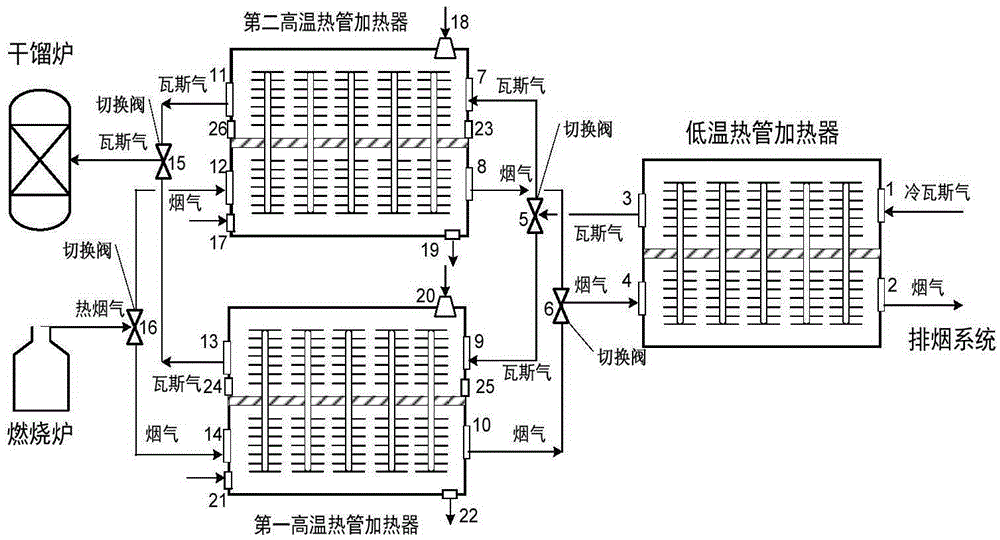

[0024] refer to figure 1 , a heat pipe heating type oil shale carbonization gas process of the present invention includes the following:

[0025] 1) Circulating gas heating process:

[0026] The low-temperature circulating gas at 25-50°C from the condensing oil recovery system enters the low-temperature heat pipe heater from the cold-circulating gas inlet 1 of the low-temperature heat pipe heater, and there are several heat exchanges between the cold-circulating gas and the low-temperature heat pipe heater The heat pipe group of the sheet performs heat exchange, heats the gas to 350-400°C, and then passes through the cold cycle gas outlet 3 of the low-temperature heat pipe heater and enters the first cycle gas under the switching of the cycle gas inlet switching valve 5 The heating process may enter the second circulating gas heating process. The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com