Longitudinal spiral mode transfer optical fiber

A mode transfer, optical fiber technology, applied in clad optical fibers, multi-layer core/clad optical fibers, optics, etc., can solve the problems of beam quality deterioration, reduce core power density, etc., to improve the output beam quality, output beam Quality improvement, the effect of realizing optical fiber single-mode transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

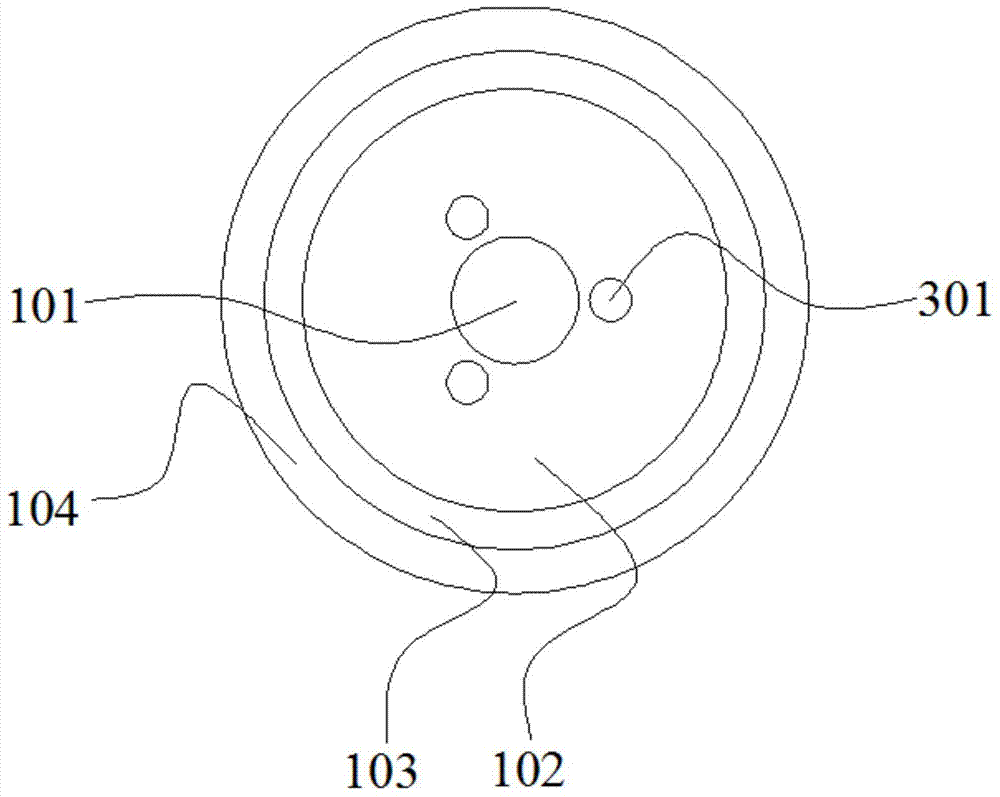

[0042] The longitudinal helical mode transfer optical fiber of embodiment 1 is a double-clad longitudinal helical mode transfer silica fiber, comprising a core 101, a cladding 102 surrounding the core, an outer cladding 103 and a coating 104; the schematic view of its end face is as follows image 3 As shown, three side cores 301 are uniformly arranged in the cladding 102 and spirally distributed longitudinally around the fiber core; viewed from the end face of the optical fiber, the three side cores are evenly distributed around the fiber core 101 in a regular triangle;

[0043] Among them, the diameter of the core 101 is 37 μm, and the numerical aperture is 0.06; the core diameter of the side core 301 is 7 μm, the numerical aperture is 0.1, the helical period is 4.5 mm, and the edge offset between the side core 301 and the fiber core 101 is 1 μm.

[0044] The refractive index of the core 101 is 1.4582, and the materials used are silica matrix, ytterbium ions, and co-dopants A...

Embodiment 2

[0046] The longitudinal helical mode transfer optical fiber of embodiment 2 is a single-clad longitudinal helical transfer silica fiber, comprising a core 101, a cladding 102 surrounding the core and a coating 104; the schematic view of its end face is as follows Figure 4 As shown, there are two layers of first layer side core 401 and second layer side core 402 of the same size that are uniformly arranged in the cladding 102 around the fiber core longitudinally; The polygons are uniformly distributed around the fiber core 101 .

[0047] Among them, the diameter of the fiber core 101 is 42 μm, and the numerical aperture is 0.065; the core diameter of the side cores 401 and 402 is 10 μm, the numerical aperture is 0.13, the helical period is 5.7 mm, and the edge offset between the side core 401 and the fiber core 101 is 2 μm.

[0048] The refractive index of the core 101 is 1.4584, and the materials used are silica matrix, ytterbium ions, and co-dopants Al ions and P ions; the ...

Embodiment 3

[0050] The longitudinal helical mode transfer optical fiber of embodiment 3 is a double-clad longitudinal helical mode transfer silica fiber comprising a core 101, a cladding 102 surrounding the core, an outer cladding 103 and a coating 104; Figure 5 As shown, in the cladding 102, there are two layers of first-layer side cores 501 and second-layer side cores 502 of two different sizes that are helically distributed around the fiber core in the longitudinal direction; 502 are uniformly distributed around the fiber core 101 in a regular hexagon.

[0051] Among them, the diameter of the fiber core 101 is 48 μm, and the numerical aperture is 0.06; the core diameter of the side core 501 is 11 μm, and the numerical aperture is 0.1; the core diameter of the side core 502 is 7.5 μm, the numerical aperture is 0.09, and the spiral period is 7 mm. The side-to-side offset from the core 101 is 3 μm.

[0052] The refractive index of the core 101 is 1.4582, and the materials used are silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com