Three-layer structural PET (polyethylene terephthalate) film and solar battery back plate prepared from three-layer structural PET film

A solar cell and three-layer structure technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low light reflectance affecting the power generation efficiency of cells, low UV resistance, and difficult repair of components, so as to improve thermal conductivity and light reflection High efficiency, good long-term aging resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

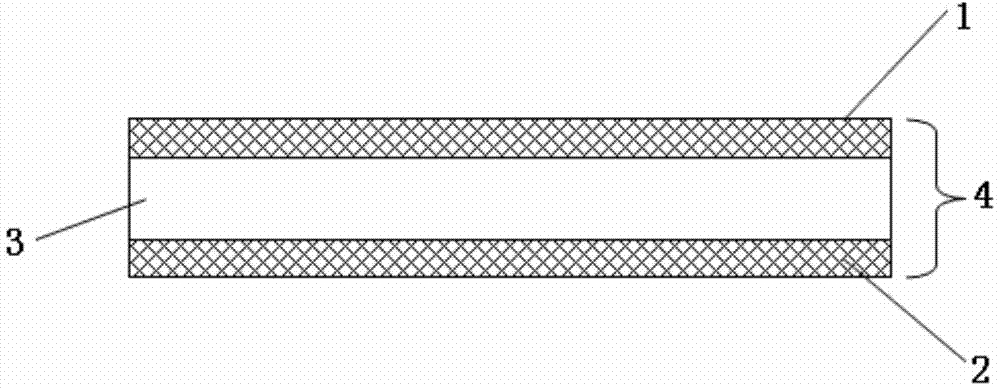

[0033] Such as figure 1 Shown is a schematic diagram of the structure of a PET film with a three-layer structure. The PET film 4 with a three-layer structure includes an intermediate layer 3 in the middle and an outer layer 1 and an inner layer 2 located on both sides of the intermediate layer. The three-layer PET film is biaxially stretched and co-extruded, and is produced continuously at one time. The thickness of the PET film 4 is 0.100mm, wherein the thickness of the outer layer 1 is 0.020mm, the thickness of the middle layer 3 is 0.060mm, and the thickness of the inner layer 2 is 0.020mm; the surface gloss of the outer layer 1 is 60, and the surface gloss of the inner layer 2 is 60, where the angle of light projection for measuring gloss is 60° in line with GB / T9754-2007 and international standard ISO2813:1994.

[0034] The outer layer 1 can block more than 99% of 280-400nm ultraviolet rays. After 280-400nm ultraviolet rays of 90KWh / ㎡ are irradiated, the yellowing index ...

Embodiment 2

[0044] The structure and preparation method of the three-layer PET film in this example are the same as in Example 1. Wherein the thickness of the PET film 4 is 0.300mm, wherein the thickness of the outer layer 1 is 0.050mm, the thickness of the middle layer 3 is 0.200mm, and the thickness of the inner layer 2 is 0.050mm; the surface gloss of the outer layer 1 is 100, and the surface gloss of the inner layer 2 for 100. The inner layer 2 contains no inorganic filler. The inner and outer layers can block more than 99% of 280-400nm ultraviolet rays. After 280-400nm ultraviolet rays are 90KWh / ㎡irradiated, the yellowing index ▽b<3; hydrolysis resistance, PCT test 121°C, 100% humidity, after 72 hours, The remaining elongation at break is above 10%. Integrating sphere method gives the inner and outer surface reflectance as 100%. The PET film 4 with the above-mentioned three-layer structure has undergone a PCT test at 121° C. and 100% humidity, and after 48 hours, there is no abnor...

Embodiment 3

[0051] The structure and preparation method of the three-layer PET film in this example are the same as in Example 1. Wherein the thickness of the PET film 4 is 1.000mm, wherein the thickness of the outer layer 1 is 0.010mm, the thickness of the middle layer 3 is 0.980mm, and the thickness of the inner layer 2 is 0.010mm, wherein the inner layer 2 contains calcium carbonate, carbon black mixed inorganic filler, containing is 10%; the surface gloss of the outer layer 1 is 10, and the surface gloss of the inner layer 2 is 10. Integrating sphere method gives the inner and outer surface reflectivity of 30%. The PET film 4 with the above-mentioned three-layer structure has undergone a PCT test at 121° C. and 100% humidity, and after 48 hours, there is no abnormal appearance, no bubbles, cracks, discoloration, etc., and the yellowing index ▽b<3.

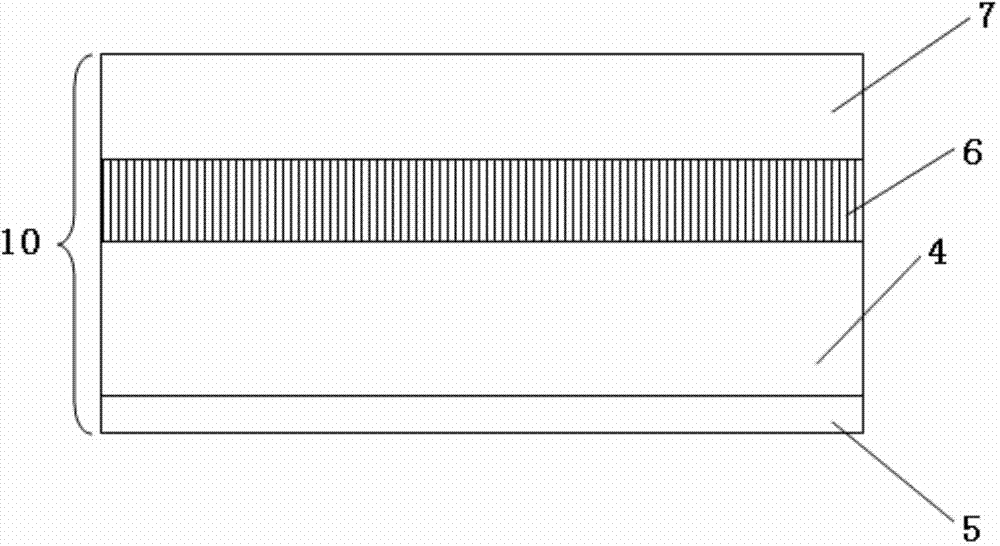

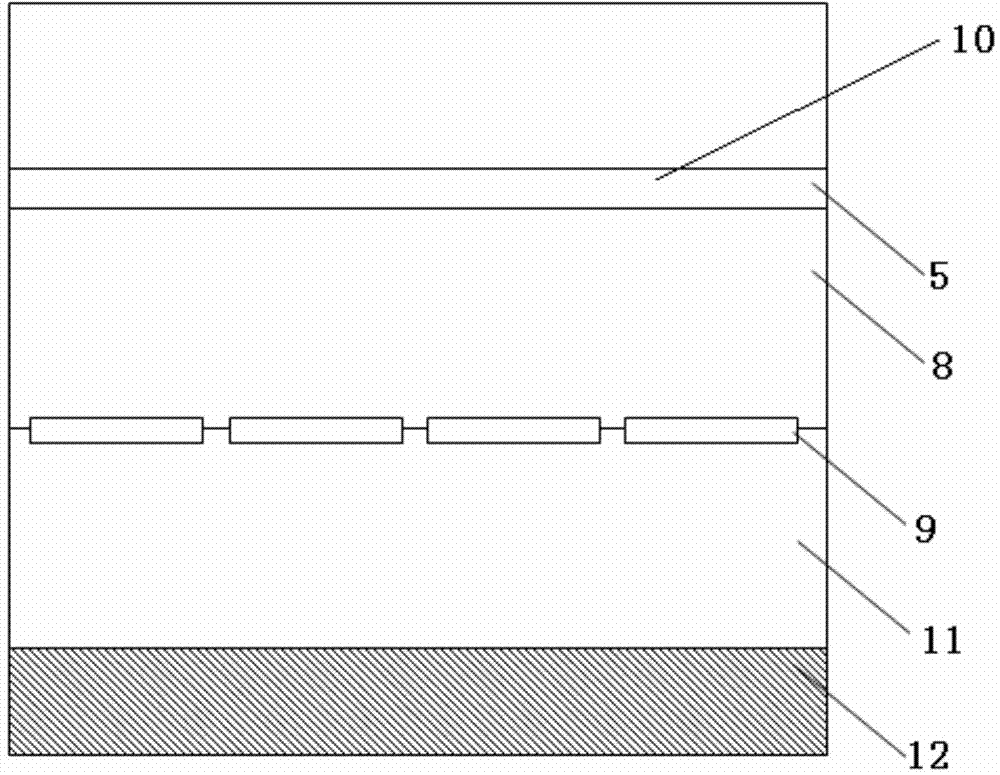

[0052] In this example, the structure of the solar cell backboard composed of the above-mentioned three-layer PET film and the assembled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com