Superhydrophobic coating composition and superhydrophobic coating formed therewith

A super-hydrophobic coating and composition technology, applied in the coating composition of super-hydrophobic coating and the field of super-hydrophobic coating, can solve the problem of complex process, high coating curing temperature, poor mechanical properties of super-hydrophobic coating, adhesion, resistance to Impact resistance, soft friction resistance and other issues, to achieve the effect of good adhesion, low curing shrinkage, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] Hereinafter, the present invention will be described in more detail with reference to Examples. However, the present invention is not limited to these examples.

[0066] The epoxy resin used in the embodiment includes: Epoxy Resin E-44 (Sanmu Group, Industrial Grade), Epoxy Resin E-51 (Wuxi Resin Factory)

[0067] The fluorine resin used in the embodiment includes: GK-570 (Daikin), FY-F535C (Guangzhou Fluorine Silicon Technology Co., Ltd.), CC1-3 (Jiaxing Kairui Technology Co., Ltd.), CC1-4 (Jiaxing Kairui Technology Co., Ltd.), WF-Q212 (Wuxi Wanbo Paint Chemical Co., Ltd.), fluororesin F0 (Sinochem Taicang).

[0068] The epoxy resin toughening agent used in the embodiment is epoxy resin toughening agent CYH-277 (Wuda Senmao Fine Chemical Co., Ltd., industrial grade).

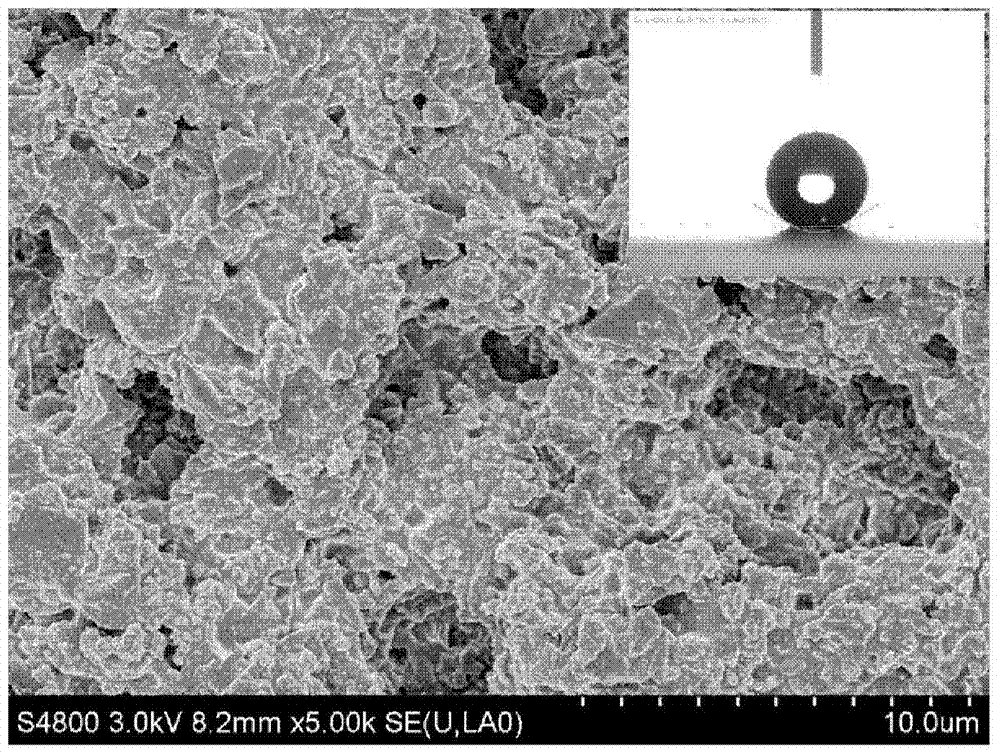

[0069] The micro-nano particles used in the embodiment include: Myrica rubra structure particles (self-made, see attached figure 2 , with hydroxyl groups on the surface), clay (Nanocor, 15-20 μm, wit...

preparation example 1

[0073] Preparation Example 1: Preparation of Waxberry Particles

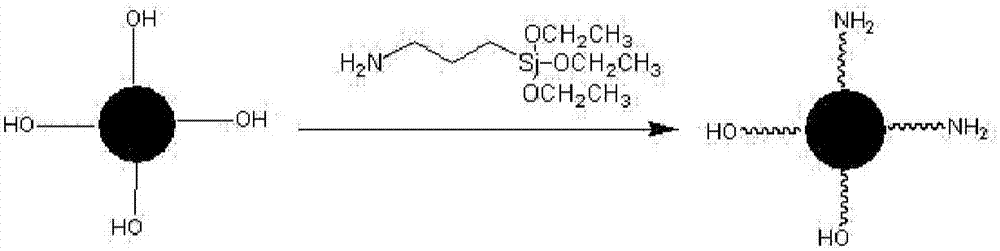

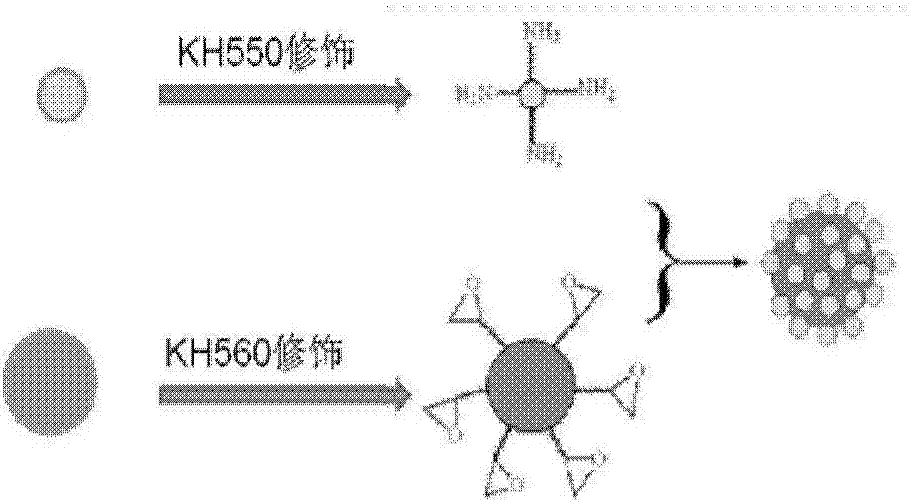

[0074] Such as image 3 As shown, small spheres of 100±20nm and large spheres of 1000±200nm were prepared by the classic Stober sol-gel method. Simply, TEOS was added to aqueous solution containing concentrated ammonia and ethanol, and reacted at 40°C for 2-6h, that is Silica spheres can be obtained, and then 1-5g of silica particles with smaller particle sizes are modified by 0.1-0.6g of silane coupling agent KH550 (Nanjing Shuguang Chemical Group Co., Ltd. Carry out polycondensation reaction with the hydroxyl groups on the surface of silica, and graft amino groups), similarly use 0.1-0.3g of silane coupling agent KH560 (Hangzhou Boiling Chemical Co., Ltd.) to modify 1-5g of silica with larger particle size Particles are grafted with epoxy groups, and the two kinds of particles are redispersed in xylene solvent, placed in an oil bath at 60-80°C for 2-6h, and finally filtered and washed to obtain the carbon dio...

Embodiment 1

[0076] 5.12 g of the myrica rubra structure particles prepared in Preparation Example 1 were dispersed in 15.10 g of n-butanol to obtain an inorganic particle suspension. Dissolve 5.06g of epoxy resin E-44 and 2.11g of epoxy resin toughener CYH-277 in a mixed solvent of 5.03g of n-butanol and xylene (mass ratio is 1:1), then 4.11g of WF-Q212, 1.98g of FY-F535C and 10.01g of CC1-3 were added to the prepared epoxy resin solution, stirred and reacted at 40°C for 2 hours to obtain a hydrophobically modified epoxy resin. Then add the suspension of inorganic particles into the hydrophobically modified epoxy resin solution, add 0.21g defoamer BYK-141 and 0.23g anti-sedimentation agent BYK-410, and filter with 40-100 mesh to get the filtrate A components.

[0077] Dissolve 5.14g of polyamide SF650 in a mixed solvent of 4.96g of n-butanol and xylene (mass ratio 1:1), and add 0.15g of accelerator DMP-30 to obtain component B.

[0078] Mix component A and component B uniformly at a rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com