Method for manufacturing low-protein rice and food using low-protein rice

A manufacturing method and protein technology, applied in the fields of food preparation, application, food science, etc., can solve the problems of low protein content, large capacity and weight, and no strong taste in low-protein rice, achieving less moisture and preventing food intake. The effect of reducing energy input and improving hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0183] Hereinafter, the present invention will be more specifically described through examples, but the present invention is not limited to the following examples.

[0184] "Manufacturing of Low-Protein Rice (1)"

[0185] Various low-protein rices are manufactured using indica rice as raw material.

[0186] First, 0.5% by mass of protease (Protease M, manufactured by Amano Enzyme Co., Ltd.) and an emulsifier preparation (trade name: Ryoto Ester SMO, manufactured by Mitsubishi Chemical Foods Co., Ltd.) were dissolved in a pH 4.0 buffer solution. Composition: 3.5% of sucrose fatty acid ester, 3.5% of glycerin fatty acid ester, 43% of oligosaccharide, 50% of water) 2% by mass to prepare a reaction liquid. 350 ml of reaction liquids were added to 75 g of indica rice (raw rice), and enzyme treatment was performed, stirring at 42 degreeC with the stirrer for 24 hours. 350 ml of water was added to the enzyme-treated rice, and the rice was stirred with a stirrer for 10 minutes and w...

Embodiment 1

[0194] (Indica rice fried processing)

[0195] The water-controlled indica rice was fried in 180° C. corn oil (trade name: Nissin Corn Oil, manufactured by Nissin Oliver Group Co., Ltd.) for 30 seconds to obtain low-protein indica rice (low-protein fried indica rice).

[0196]

[0197] The moisture content of the rice was measured using a moisture meter (SMART SYSTEM 5, manufactured by CEM Corporation). The results are shown in Table 1.

[0198] [Table 1]

[0199] Table 1

Moisture content(g / 100g)

Raw material Indica rice (raw rice)

12.6

Rice of Comparative Example 1

15.1

Rice of Comparative Example 2

13.5

The rice of embodiment 1

6.9

[0200] According to the production method of the present invention, low-protein rice having a moisture content of 10% by mass or less can be obtained with good storage stability.

[0201]

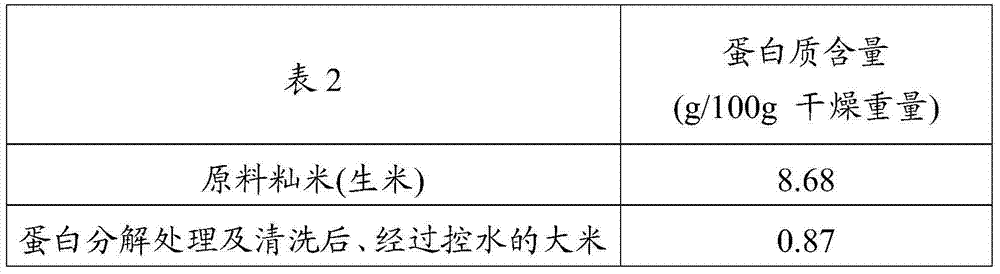

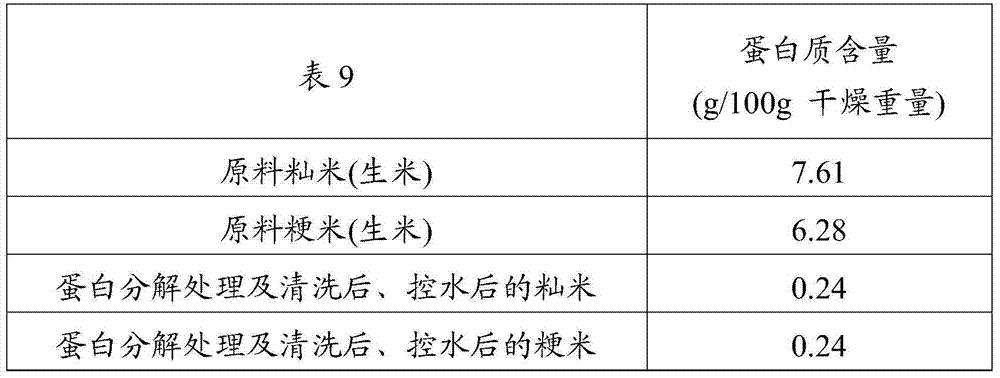

[0202] The protein content in the dried rice was determined by the Kjeldahl method. ...

Embodiment 2

[0256] (Indica rice fried processing)

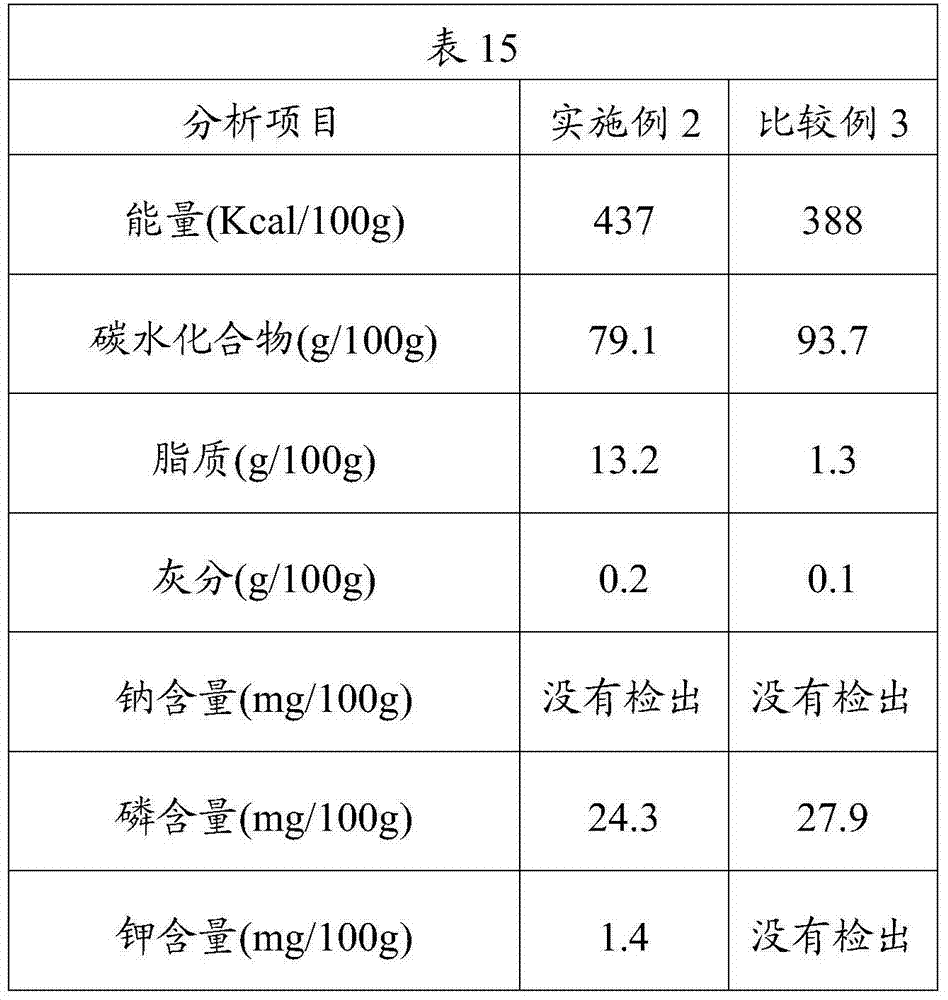

[0257] The indica rice after water control is fried in 180 ℃ rapeseed oil (trade name: Nissin Corona Oil, manufactured by Nissin Oiliyo Group (Co., Ltd.)) for 30 seconds to obtain low-protein indica rice (low-protein oil fried indica rice).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com