Extraction process of large-scale production of Angelica dahurica extract in Angelica dahurica medicinal materials

An extract and extraction technology of Angelica dahurica, applied in the direction of pharmaceutical formula, plant raw materials, plant/algae/fungus/moss components, etc., can solve air environment, production environment pollution, inconvenient feeding and use of solid preparations, and unsuitable for large-scale production and other problems, to achieve the effect of less solvent species, easy promotion and use, and less quantity involved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

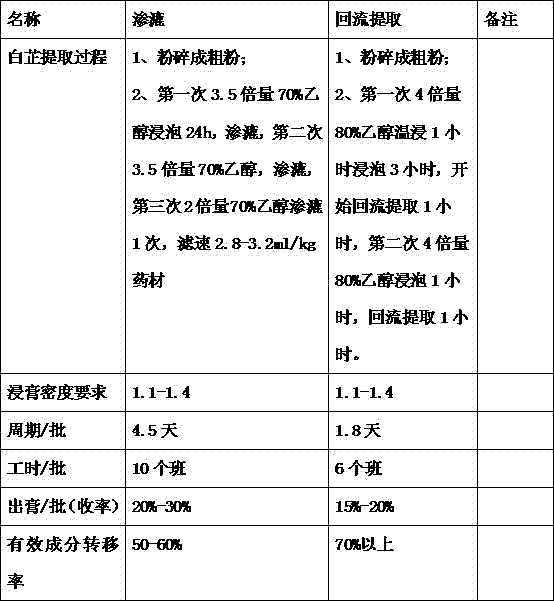

Method used

Image

Examples

Embodiment 1

[0021] Embodiment one, its processing step is:

[0022] 1. Clean selection: the impurities and non-medicinal parts of Angelica dahurica are sorted out and discarded;

[0023] 2. Crushing: crushing the selected Angelica dahurica medicinal materials into coarse powder;

[0024] 3. One-time reflux: put 200kg of Baizhi coarse powder into the extraction tank, add 800kg of 75% ethanol to the extraction tank, heat to 60°C for 1-1.5 hours, stop heating and soak for 3 hours, and control the heating temperature again at 75-78°C to start timed reflux extraction Obtain a volume of 600L extract in 1 hour, and transport the extract to the liquid medicine storage tank;

[0025] 4. Secondary reflux: add 1000kg of 75% ethanol to the extraction tank, soak at room temperature for 1 hour, control the heating temperature again at 75-78°C and start timed reflux extraction for 1 hour to obtain a volume of 780L extract, transport the extract to the liquid storage tank and merge twice extract; ...

Embodiment 2

[0028] Embodiment two, its processing step is:

[0029] 1. Clean selection: the impurities and non-medicinal parts of Angelica dahurica are sorted out and discarded;

[0030] 2. Crushing: crushing the selected Angelica dahurica medicinal materials into coarse powder;

[0031] 3. One-time reflux: put 200kg of coarse powder of Angelica dahurica into the extraction tank, add 900kg of 80% ethanol to the extraction tank, heat to 60°C and soak for 1-1.5 hours, stop heating and soak for 3 hours, and control the heating temperature at 75-78°C to start timed reflux Extract for 1 hour to obtain a volume of 650L extract, and transport the extract to the liquid medicine storage tank;

[0032] 4. Secondary reflux: Add 900kg of 80% ethanol to the extraction tank, soak at room temperature for 1 hour, reheat the temperature at 75-78°C and start reflux extraction for 1 hour to obtain a volume of 770L extract (vapor pressure≦0.1Mpa), and transport the extract to The liquid medicine storag...

Embodiment 3

[0035] Embodiment three, its processing step is:

[0036] 1. Clean selection: the impurities and non-medicinal parts of Angelica dahurica are sorted out and discarded;

[0037] 2. Crushing: crushing the selected Angelica dahurica medicinal materials into coarse powder;

[0038] 3. One-time reflux: put 200kg of coarse powder of Angelica dahurica into the extraction tank, add 1000kg of 85% ethanol to the extraction tank, heat to 60°C, soak for 1-1.5 hours, stop heating and soak for 3 hours, and control the heating temperature at 75-78°C to start timing reflux Extract for 1 hour to obtain a volume of 700L extract, and transport the extract to the liquid medicine storage tank;

[0039] 4. Secondary reflux: Add 800kg of 85% ethanol to the extraction tank, soak at room temperature for 1 hour, control the heating temperature again at 75-78°C and start timed reflux extraction for 1 hour to obtain a volume of 760L extract (vapor pressure≦0.1Mpa), and transport the extract To the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com