A kind of preparation method of regular spherical silver nanoparticles

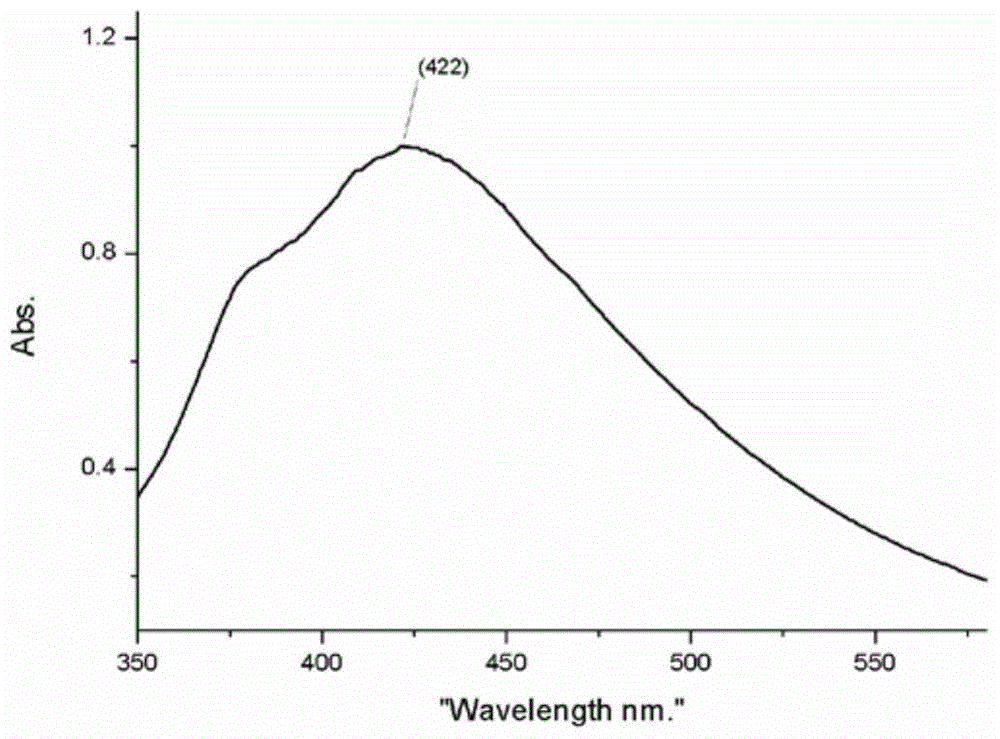

A silver nanoparticle and spherical technology, applied in the direction of nanotechnology, etc., to achieve the effect of easy to meet the experimental conditions, excellent plasma resonance characteristics, and simple and easy experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A preparation method of regular spherical silver nanoparticles, characterized in that the preparation method comprises the following steps:

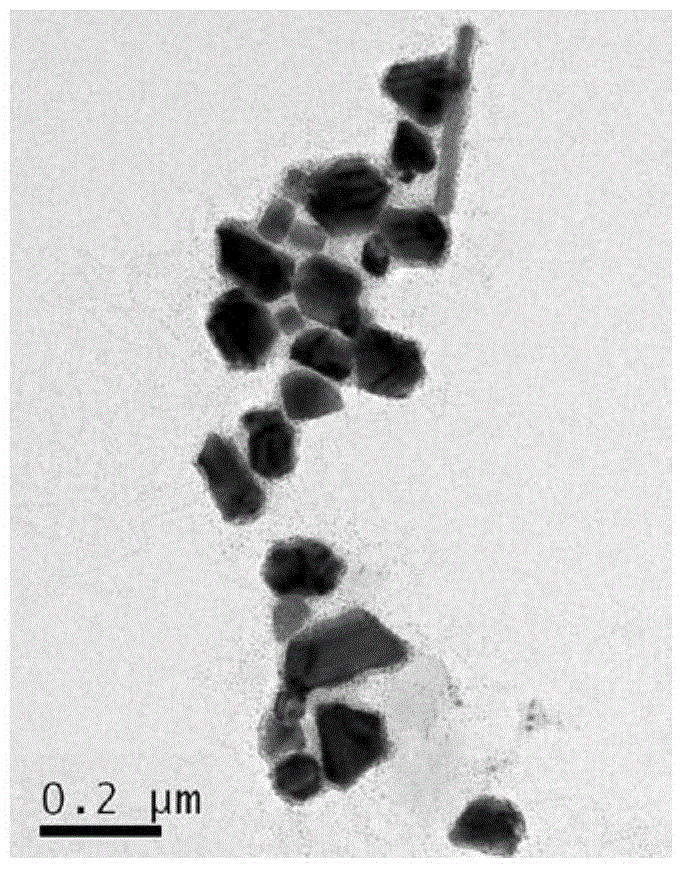

[0062] 10. Preparation of irregular silver nanoparticles precursor colloid. Include the following steps:

[0063] 101. Clean a 700ml beaker with alcohol and ultrapure water in sequence, add 500ml of silver nitrate solution with a concentration of 0.53mmol / L, place it on an electric stove, and heat it to boiling. Using a separatory funnel, 10 ml of a sodium citrate solution with a concentration of 3.4 mmol / L was added dropwise to the solution, and at the same time, a stirrer was used for rapid physical stirring.

[0064] 102. After the reaction time is about 25 minutes, turn off the electric furnace, and let the prepared precursor colloid cool down to room temperature naturally.

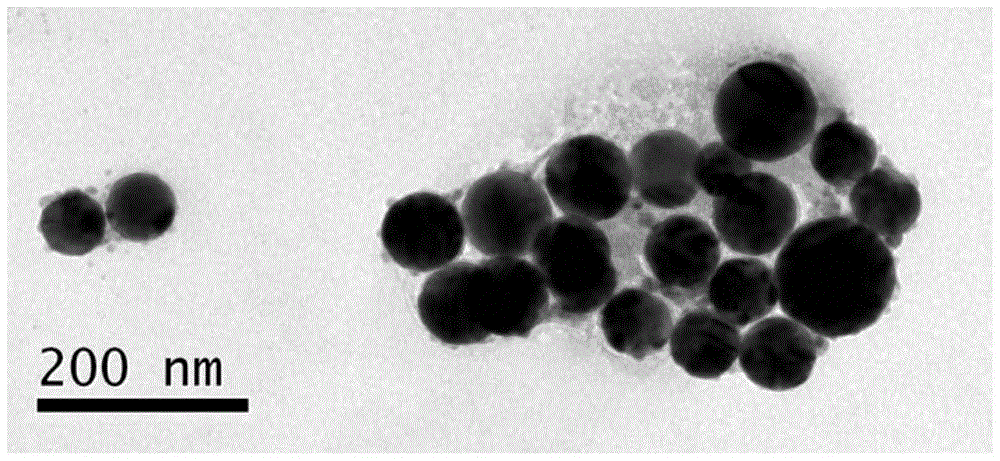

[0065] 20. Preparation of regular spherical silver nanoparticles by using precursor silver colloid. Include the following steps:

[0066] 201. Place ...

Embodiment 2

[0072] A preparation method of regular spherical silver nanoparticles, characterized in that the preparation method comprises the following steps:

[0073] 10. Preparation of irregular silver nanoparticles precursor colloid. Include the following steps:

[0074] 101. Clean a 700ml beaker with alcohol and ultrapure water in sequence, add 500ml of silver nitrate solution with a concentration of 0.53mmol / L, place it on an electric stove, and heat it to boiling. Using a separatory funnel, 10 ml of a sodium citrate solution with a concentration of 3.4 mmol / L was added dropwise to the solution, and at the same time, a stirrer was used for rapid physical stirring.

[0075] 102. After the reaction time is about 25 minutes, turn off the electric furnace, and let the prepared precursor colloid cool down to room temperature naturally.

[0076] 20. Preparation of regular spherical silver nanoparticles by using precursor silver colloid. Include the following steps:

[0077] 201. Place ...

Embodiment 3

[0083] A preparation method of regular spherical silver nanoparticles, characterized in that the preparation method comprises the following steps:

[0084] 10. Preparation of irregular silver nanoparticles precursor colloid. Include the following steps:

[0085] 101. Clean a 700ml beaker with alcohol and ultrapure water in sequence, add 500ml of silver nitrate solution with a concentration of 0.53mmol / L, place it on an electric stove, and heat it to boiling. Using a separatory funnel, 10 ml of a sodium citrate solution with a concentration of 3.4 mmol / L was added dropwise to the solution, and at the same time, a stirrer was used for rapid physical stirring.

[0086]102. After the reaction time is about 25 minutes, turn off the electric furnace, and let the prepared precursor colloid cool down to room temperature naturally.

[0087] 20. Preparation of regular spherical silver nanoparticles by using precursor silver colloid. Include the following steps:

[0088] 201. Place 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com