Potassium sulphate reaction furnace

A reaction furnace, potassium sulfate technology, applied in the directions of alkali metal sulfite/sulfite, alkali metal compound, sustainable manufacturing/processing, etc., can solve the problems of easy corrosion, small heat transfer area, low heat transfer efficiency, etc. Achieve the effects of high corrosion resistance, good economic benefits and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

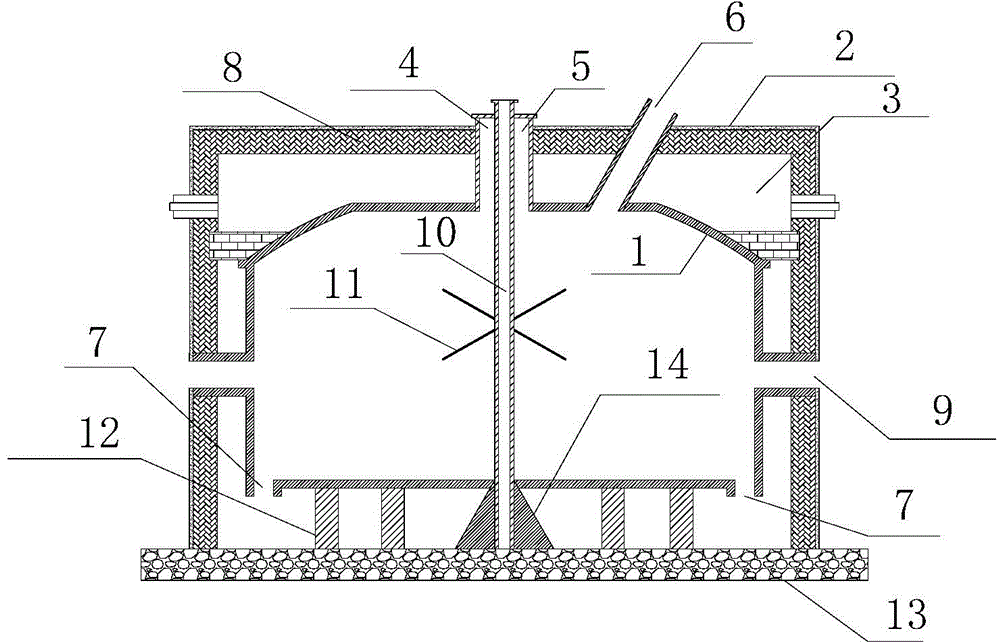

[0024] see figure 1 , the present invention proposes a potassium sulfate reaction furnace, comprising a reaction furnace 1, an outer layer of furnace body 2 surrounding the periphery of the reaction furnace, and a fire channel 3 arranged between the reaction furnace and the outer layer of furnace body; the material selection of the reaction furnace 1 Existing nickel-chromium alloy; can also be selected including mass ratio of nickel 20%-30%, chromium 20%-30%, and the rest is rare earth nickel-chromium alloy. The best selection is nickel-chromium alloy including 20%-30% nickel by mass, 25%-30% chromium and the rest are rare earths.

[0025] The top of reaction furnace 1 is provided with feed inlet, and feed inlet is two, is respectively the concentrated sulfuric acid feed inlet 4 and potassium chloride feed inlet 5; The top of reaction furnace 1 is also provided with hydrogen chloride gas discharge outlet 6, reaction The lower part of the furnace 1 is provided with two potassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com