Saury antioxidative peptide as well as separation and extraction method and application thereof

A technology of antioxidant peptides and extraction methods, applied in the fields of application, peptides, food preparation, etc., can solve problems such as waste of resources, achieve the effects of improving flavor, increasing utilization rate and added value, and improving food stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Remove the head and viscera of the saury, wash the blood, and twist it into surimi, mix the surimi with water at a mass ratio of 1:2, add flavor protease, the addition amount is 1500U / g protein, at a pH of 6.5, Enzymolysis at 45°C for 4 hours; incubation at 85°C for 30 minutes, centrifugation at 1500g for 30 minutes, and supernatant to obtain saury protein hydrolyzates (PSPHs), with a degree of hydrolysis of 13.10%±0.72%;

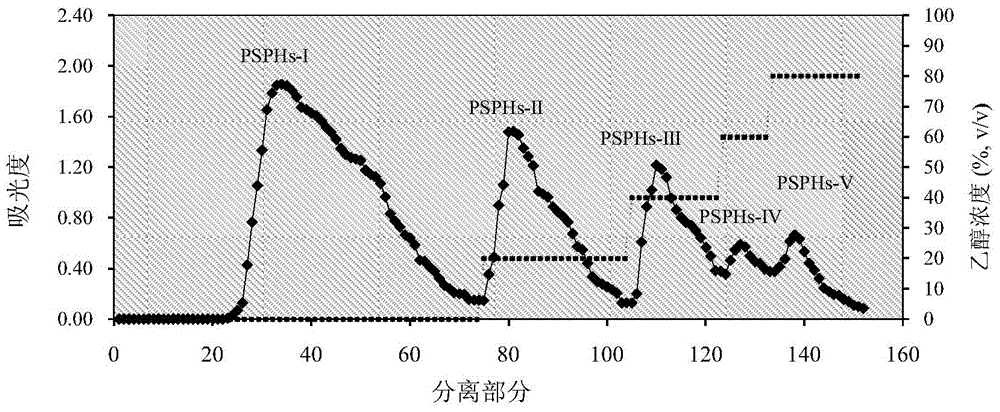

[0033] (2) Use HP-20 macroporous adsorption resin to separate PSPHs. After loading the sample, use distilled water and gradient elution with volume fractions of 10%, 30%, 50% and 70% ethanol solution, and collect 30% ethanol solution for elution The components were freeze-dried to obtain peptide powder I;

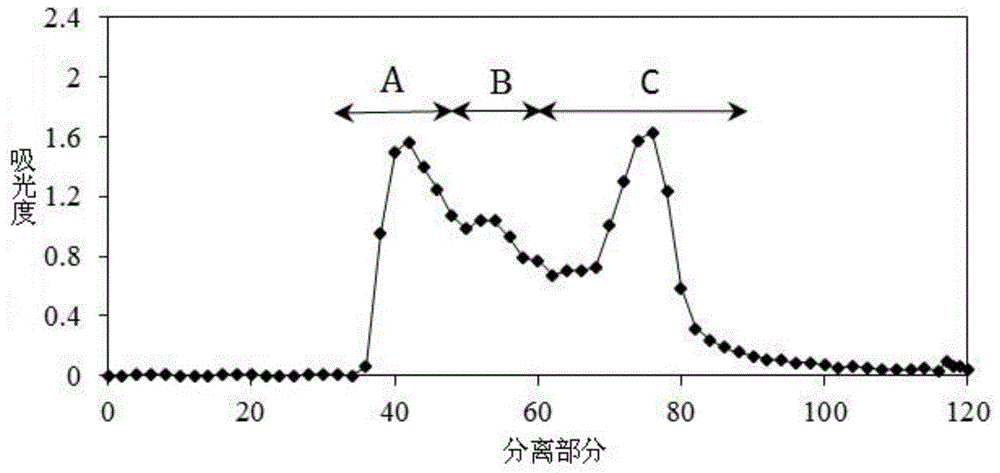

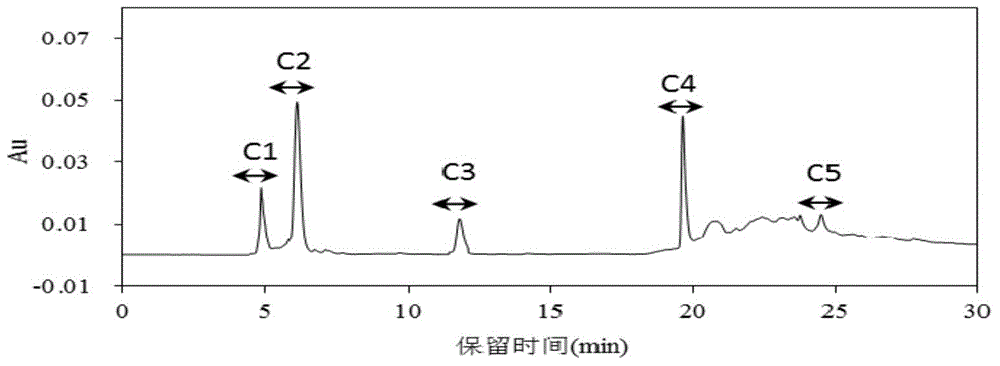

[0034] (3) Separate the peptide powder I with a Sephadex G-25 Sephadex chromatographic column, elute with distilled water as the mobile phase, obtain three components in sequence according to the elution time, and collect the last eluted compo...

Embodiment 2

[0038] (1) Remove the head and viscera of the saury, clean the blood and twist it into surimi, mix the surimi with water at a mass ratio of 1:2, add trypsin, the addition amount is 500U / g protein, at a pH of 8.5, Enzymolysis at 55°C for 8 hours; incubation at 100°C for 10 minutes, centrifugation at 4000g for 10 minutes, and supernatant to obtain saury protein hydrolyzates (PSPHs), with a degree of hydrolysis of 15.58%±0.55%;

[0039] (2) Use HP-20 macroporous adsorption resin to separate PSPHs. After loading the sample, use distilled water and gradient elution with volume fractions of 29%, 49%, 69% and 90% ethanol solution, and collect 49% ethanol solution for elution The components were freeze-dried to obtain peptide powder I;

[0040] (3) Separate the peptide powder I with a Sephadex G-25 Sephadex chromatographic column, elute with distilled water as the mobile phase, obtain three components in sequence according to the elution time, and collect the last eluted component , ...

Embodiment 3

[0044] (1) Remove the head and viscera of the saury, wash the blood and twist it into surimi, mix the surimi and water at a mass ratio of 1:4, add a mixed enzyme of flavor protease and pancreatin, and add an amount of 1000U / g protein , under the conditions of pH 7.5 and temperature 50°C for 12 hours; at 95°C for 15 minutes, centrifuged for 20 minutes under a centrifugal force of 2500g, and the supernatant was taken to obtain saury protein enzymatic hydrolyzate (PSPHs), the degree of hydrolysis was 18.72% ±0.95%;

[0045] (2) Use HP-20 macroporous adsorption resin to separate PSPHs. After loading the sample, use distilled water and gradient elution with volume fractions of 20%, 40%, 60% and 80% ethanol solution successively, and collect 40% ethanol solution for elution The components were freeze-dried to obtain peptide powder I;

[0046] (3) Separate the peptide powder I with a Sephadex G-25 Sephadex chromatographic column, elute with distilled water as the mobile phase, obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com