Rotary kiln combustion control device and method

A control device and technology of rotary kiln, applied in combustion method, controlled combustion, rotary drum furnace, etc., can solve the problems of uneven control level of operators, difficult implementation, serious agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

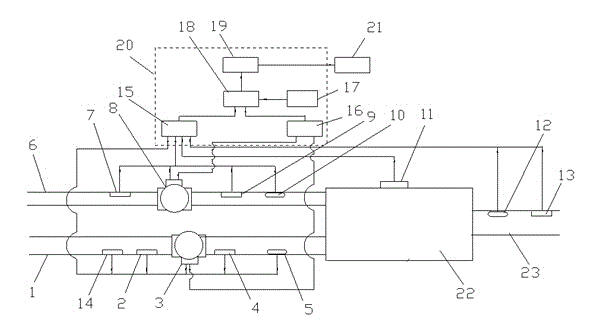

[0059] As shown in the figure, the present invention includes a gas flow measuring device 2, a gas flow regulating device 3, a gas pressure measuring device 4, a gas temperature measuring device 5, a combustion-supporting air flow measuring device 7, a combustion-supporting air flow regulating device 8, and a combustion-supporting air pressure measuring device 9. Combustion air temperature measuring device 10, rotary kiln wireless temperature measuring device 11, flue temperature measuring device 12, flue oxygen content measuring device 13 and gas composition measuring device 14. The present invention also includes an input module 15 , an output module 16 , a power supply module 17 , a CPU control device 18 , an interface module 19 , a bus backplane module 20 and a display device 21 . Among them: input module 15, output module 16, power supply module 17, CPU control device 18, interface module 19, bus backplane module 20 and display device 21 are PLC or DCS standard hardware. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com