Preparation method and application of activated carbon for recycling gold

A technology of activated carbon preparation and activated carbon, which is applied in the direction of chemical instruments and methods, improvement of process efficiency, and other chemical processes. Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

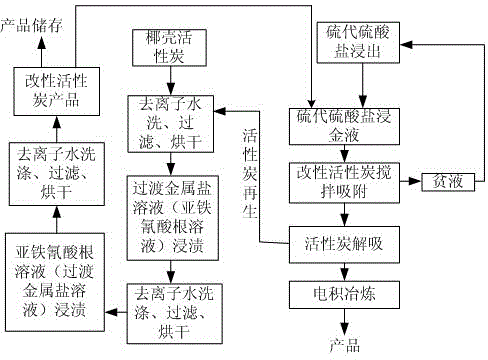

Image

Examples

Embodiment 1

[0025] (1) Take 3g of granular activated carbon, wash with deionized water, remove powder dust, filter, and bake at 106°C for 12h;

[0026] (2) The activated carbon dried in step (1) was impregnated with copper (Cu 2+ ) solution at room temperature (stirring speed: 50 r / min) for 4 h; then pour out the supernatant, wash with deionized water, filter, and bake at 80°C for 4 h;

[0027] (3) Immerse the activated carbon dried in step (2) in the proportion of 100g / L in the potassium ferrocyanide solution with a concentration of 0.02 mol / L and stir at room temperature (stirring speed is 50 r / min) for 4 h Then pour out the supernatant, wash with deionized water, and filter; bake at 106°C for 12 h to prepare the final activated carbon product for later use;

[0028] (4) Taking a leaching solution of waste electronic components with a gold content of about 105 g / t as an example, the leaching solution contains dithiosulfuric acid alloy (Ⅰ) ([Au(S 2 o 3 ) 2 ] 3- ) concentration is 2m...

Embodiment 2

[0030] (1) Take 3g of columnar activated carbon, wash with deionized water, remove powder dust, filter, and bake at 110°C for 1h;

[0031] (2) The activated carbon dried in step (1) was impregnated in Ag-containing (Ag + ) solution at room temperature (stirring speed: 100 r / min) for 2 hours; then pour out the supernatant, wash with deionized water, filter, and bake at 90°C for 1 hour;

[0032] (3) Immerse the activated carbon dried in step (2) in the proportion of 500g / L in the potassium ferrocyanide solution with a concentration of 0.02 mol / L and stir at room temperature (stirring speed is 150r / min) for 2h; then Pour out the supernatant, wash with deionized water, and filter; bake at 100°C for 5 hours to prepare the final activated carbon product for use;

[0033] (4) Add 1 g of activated carbon obtained in step (3) into the simulated thiosulfate gold leaching solution, which contains [Au(S 2 o 3 ) 2 ] 3- The concentration is 100ppm, the pH value is 5, and after 24 hours...

Embodiment 3

[0035] (1) Take 3g of granular coconut shell activated carbon and wash it with deionized water to remove powder dust, filter, and bake at 100°C for 6 hours;

[0036] (2) The activated carbon dried in step (1) is impregnated in the concentration of 0.005mol / L containing Cd (Cd 2+ ) solution at room temperature (stirring speed: 250r / min) for 0.5h; then pour out the supernatant, wash with deionized water, filter, and bake at 100°C for 12h;

[0037] (3) Immerse the activated carbon dried in step (2) in the proportion of 250g / L in the potassium ferrocyanide solution with a concentration of 0.005mol / L and stir at room temperature (stirring speed is 200 r / min) for 3 hours; Then pour out the supernatant, wash with deionized water, and filter; bake at 110°C for 1 hour to prepare the final activated carbon product for later use;

[0038] (4) Taking an ore leaching solution with a gold content of about 2.67 g / t as an example, the leaching solution contains dithiosulfuric acid alloy (I) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com