Method for preparing titanium oxide photocatalyst

A technology of photocatalyst and titanium oxide, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as insufficient catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

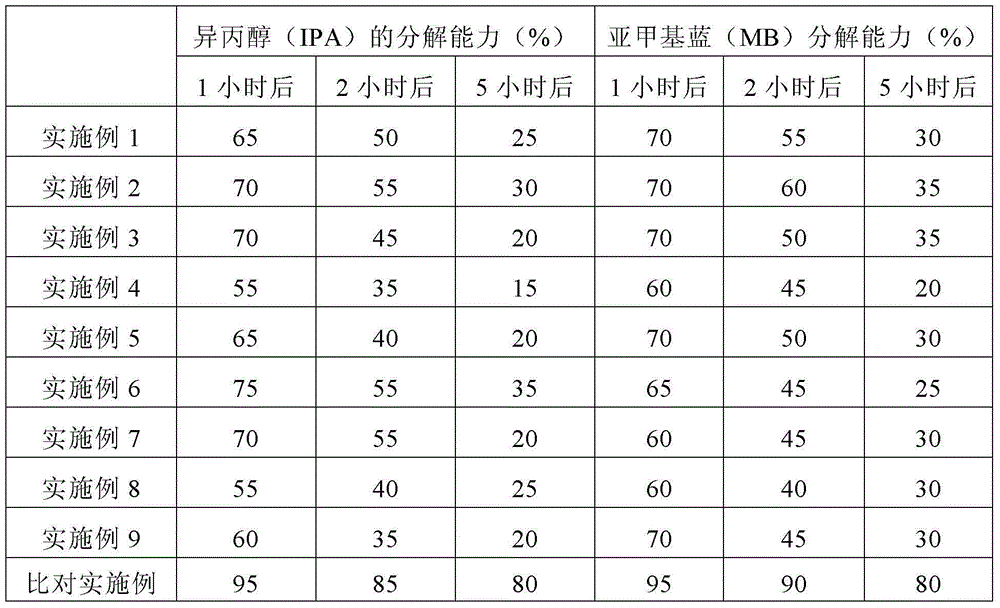

Embodiment 1

[0048] Dissolve 12g of titanium tetrachloride in 300g of pure water, add 9.7g of thiourea, heat up to 60°C under stirring, add 10wt% ammonia water continuously to keep the reaction system at pH=7.4, control the temperature and pH value to react After cooling down for 1 hour, suction filtration, the obtained solid phase was washed with pure water for 0.5 hours under stirring, and the solid phase obtained by suction filtration was dried at a temperature of 50°C in a spray dryer, and then placed in a sintering furnace, at 400 °C for 3 hours in vacuum, the resulting solid was ground in a ball mill, washed with pure water, and dried at 50 °C to obtain a titanium oxide photocatalyst. The sulfur content of the titanium oxide photocatalyst was determined The amount is 0.25wt%, the proportion of rutile type and anatase type is 10%, and the specific surface area is 180m 2 / g. The decomposition ability of isopropanol (IPA) and the decomposition ability of methylene blue (MB) are listed ...

Embodiment 2

[0050] Dissolve 20g of titanium tetrachloride in 300g of pure water, add 10.0g of dimethylthiourea, heat up to 50°C under stirring, add 30wt% ammonia water continuously to keep the reaction system at pH=7.8, control the temperature and The pH value was reacted for 2 hours, and suction filtered after cooling down. The obtained solid phase was washed with pure water for 1 hour under stirring, and the solid phase obtained by suction filtration was dried at a temperature of 60°C in a spray dryer, and then it was Put it in a sintering furnace, and roast it under vacuum at 450°C for 5 hours, put the obtained solid into a ball mill for grinding, wash it with pure water, and dry it at 60°C to obtain a titanium oxide photocatalyst. The sulfur content is 0.05wt%, the ratio of rutile and anatase is 60%, and the specific surface area is 170m 2 / g.

Embodiment 3

[0052] Dissolve 10g of titanium tetrachloride in 300g of pure water, add 9.7g of thiourea, heat up to 40°C under stirring, add 10wt% ammonia water continuously to keep the reaction system at pH=7.2, control the temperature and pH value to react After cooling down for 1 hour, suction filtration, the obtained solid phase was washed with pure water for 1 hour under stirring, and the solid phase obtained by suction filtration was dried at a temperature of 70°C in a spray dryer, and then placed in a sintering In the furnace, at a temperature of 600°C, air with a volume content of 2% hydrogen was fired for 4 hours, and the obtained solid was ground in a ball mill, washed with pure water, and dried at 70°C to obtain titanium oxide light. Catalyst, the sulfur content of the titanium oxide photocatalyst is determined to be 0.18wt%, the ratio of rutile type and anatase type is 10%, and the specific surface area is 150m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com