Heavy oil catalytic cracking catalyst and preparation method thereof and heavy oil catalytic cracking method

A cracking catalyst, heavy oil catalysis technology, applied in catalytic cracking, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problem that the yield of light oil is not obvious, the coke effect is not obvious, the ratio of catalyst molecular sieve to carrier is not suitable, dry gas, The problem of high liquefied gas yield can achieve the effect of improving catalyst conversion rate, high activity stability, and improving total liquid yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

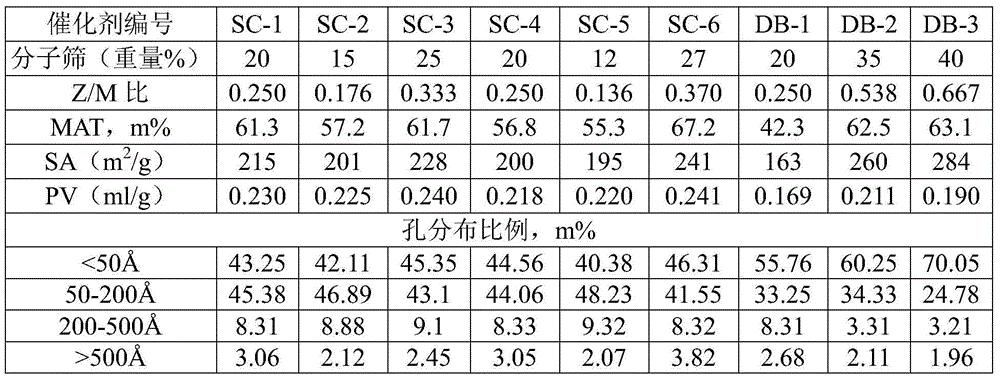

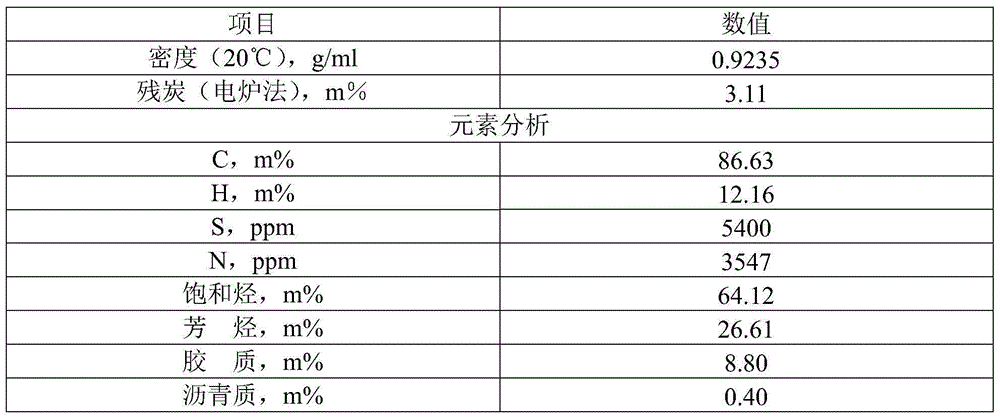

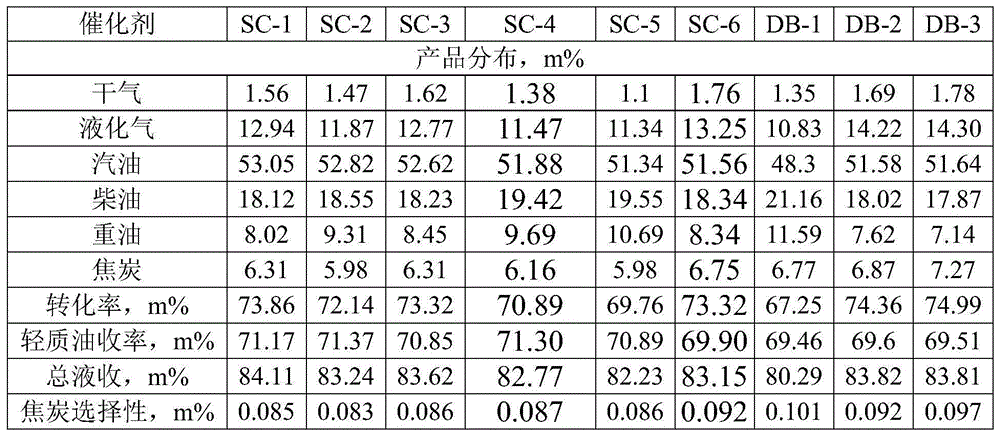

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing a heavy oil catalytic cracking catalyst, the method comprising: (1) mixing clay with water and performing acidification for the first time to obtain an acidified slurry, mixing alumina hydrate with the acidified slurry to obtain slurry, mixing at least one silicon source with the slurry to obtain a carrier slurry; (2) mixing the carrier slurry, surfactant and molecular sieve and performing second acidification to obtain a catalyst slurry; Spray granulation, roasting, washing and drying.

[0029] In the preparation method of the heavy oil catalytic cracking catalyst provided by the present invention, no aluminum sol binder is used in the preparation of the carrier slurry in step (1), which can ensure smooth pores of the prepared heavy oil catalytic cracking catalyst. The first acidification is carried out before the hydrated alumina, and the first acid solution added in the first acidification can react with the ...

Embodiment 1

[0051] This example illustrates the preparation method of the catalyst provided by the present invention.

[0052] (1) Prepare carrier slurry. After mixing 15.38 kg of kaolin (China Kaolin Company, with an alumina content of 36% by weight and a content of 78% by weight on a dry basis) and 48.00 kg of deionized water to make a slurry, acidify with 2180 ml of 30% by weight hydrochloric acid for 20 minutes. Add 14.75 kg of pseudo-boehmite (Hunan Yueyang Changke Chemical Co., Ltd., the content of alumina is 61% by weight, and the content of dry basis is 63% by weight), and after fully stirring for 40 minutes, add 10 kg of water glass at a uniform speed under rapid stirring (produced by Jinan Guoshi Weiye Co., Ltd., SiO 2 15% by weight, 20% by weight on a dry basis) and 3.75 kg of polyethyl silicate (produced by Qingdao Jiyida Silicone Reagent Factory, SiO 2 The content is 40% by weight, and the content on a dry basis is 70% by weight), the addition time is controlled to be 30 mi...

Embodiment 2

[0056] This example illustrates the preparation method of the catalyst provided by the present invention.

[0057] (1) Prepare carrier slurry. 21.15 kg of kaolin and 41.25 kg of decationized water were mixed and beaten evenly, and acidified with 2400 ml of 30% by weight hydrochloric acid for 40 minutes. Add 10.82 kg of boehmite, stir thoroughly for 20 minutes, then add 10.67 kg of water glass and 2.67 kg of silica sol (produced by Qingdao Jiyida Silica Gel Reagent Factory, SiO 2 The content is 30% by weight, the content on a dry basis is 30.5% by weight), the total addition time is controlled to be 20 minutes, and the reaction is fully performed for 40 minutes to obtain a carrier slurry.

[0058] (2) Catalyst preparation. Add 225 grams of diethanolamine aqueous solution to the carrier slurry obtained in step (1), stir for 30 minutes, add 15.52 kilograms of REY molecular sieve slurry (the content on a dry basis is 29% by weight, produced by Shandong Qilu Huaxin Hi-Tech Co., Ltd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com