A kind of preparation method of high light transmittance coated photovoltaic glass

A photovoltaic glass and high light transmittance technology, applied in the field of solar cells, can solve problems such as poor durability, poor weather resistance, and technical bottlenecks, and achieve the effects of ensuring long-term durability, increasing output power, and dense and uniform film layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the high light transmittance coated photovoltaic glass provided in this embodiment includes the following steps:

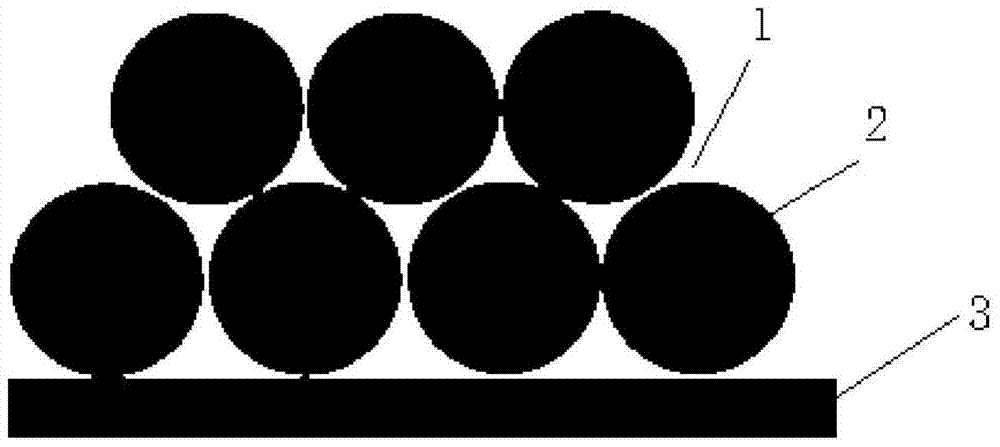

[0028] (1) In order to form a layer of crystal grains with a positive pyramid structure on the photovoltaic glass surface, a wet etching technique is adopted, which is divided into three steps: a. the etchant (10% HF solution by mass percentage ) moves to the surface of the silicon wafer; b. chemically reacts with the exposed glass for 550-650 seconds to generate soluble by-products; c. removes the reaction product from the glass surface, and the etchant is 10% by mass. HF solution, because the concentration of HF solution on SiO 2 It has a very high corrosion selectivity, and the main component of the glass is SiO 2 , while SiO 2 There are many crystal orientations in itself, so the acidic solution is used to preferentially corrode the defects in the crystal lattice, and the crystal orientation with less atomic accumulation and ...

Embodiment 2

[0031] The preparation method of the high light transmittance coated photovoltaic glass provided in this embodiment includes the following steps:

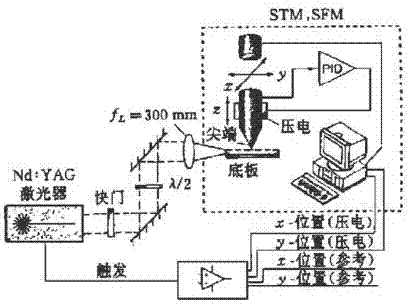

[0032] (1) In order to form a layer of positive pyramid structure grains on the surface of photovoltaic glass, dry etching technology is used to focus the 532nm frequency doubled YAG laser to the scanning tunneling microscope and the working area ( Figure 4 The base plate in is the tip of the photovoltaic glass surface). Close to the tip, due to the combination of Rayleigh scattering and surface plasmon excitation, the field strength can be increased by 1 million times, so that it can produce a channel with a width of about 10nm, which can be repeatedly etched on the same channel, while gradually reducing the number of etches. The width of the eclipse can form regular pyramidal grains, such as Figure 4 shown in . The specific process parameters are as follows: the pulse energy is 50 μJ, the laser repetition rate is 1000 Hz, and...

Embodiment 3

[0036] The preparation method of the high light transmittance coated photovoltaic glass provided in this embodiment includes the following steps:

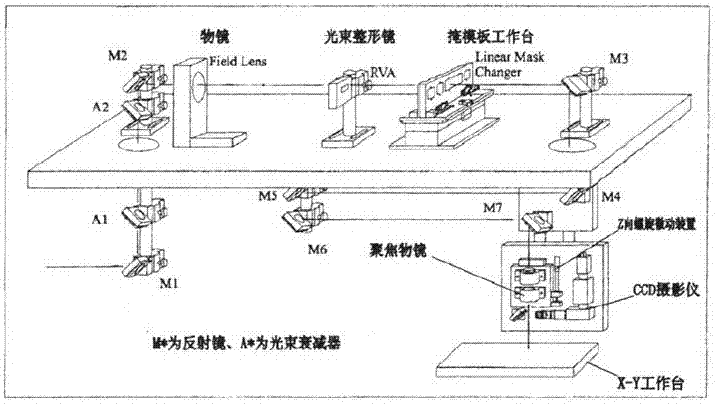

[0037] (1) In order to form a layer of crystal grains with a regular pyramid structure on the surface of photovoltaic glass, dry etching technology is used. During dry etching, an excimer laser is used, which is sequentially collimated and corrected, and the beam is shaped to form a spot area A flat and uniform rectangular beam of 12mm×24mm, namely Figure 5The incident laser beam on the left is shown, and the beam is reshaped and filtered by the mask grating to form an image source. In addition, between the two mirrors M1 and M2 in the optical path diagram, there are two attenuation lenses with attenuation rates of 95% (A1) and 50% (A2) to choose from, which are used to align the pulse energy of the excimer laser. Make adjustments. In the optical path, the positions of the reflecting mirrors M5 and M6 are adjustable in the horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com