Preparation method of high-grafting-ratio epoxied carbon nano tube additive for prepreg resin

An epoxidized carbon and nanotube technology is applied in the field of preparation of epoxidized carbon nanotube additives for prepreg resin, and can solve the problems of polluting the environment and increasing the complexity of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

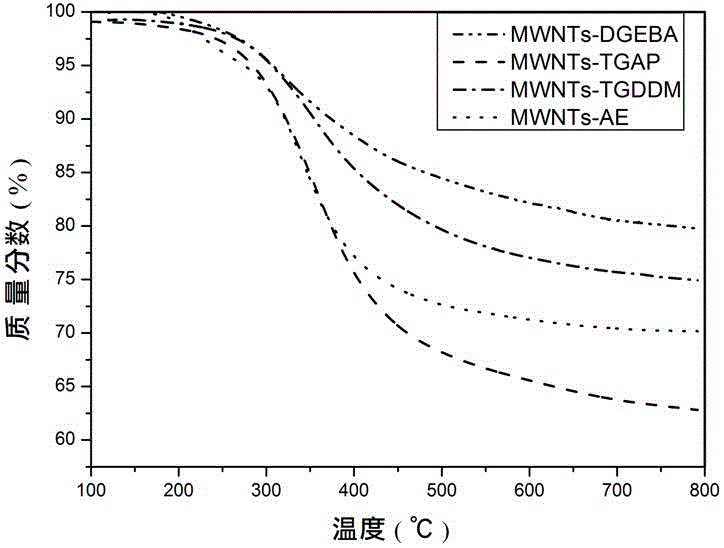

Embodiment 1

[0034] Raw material 1 is multi-walled carbon nanotubes with a purity of >95%, a diameter of 10-20 nm, and a length of 0.5-500 μm, produced by Shenzhen Nanoport Co., Ltd.;

[0035] The ratio of raw material 2 mixed acid is concentrated sulfuric acid / concentrated nitric acid = 4 / 1 (volume ratio), all produced by Beijing Chemical Reagent Company;

[0036] Raw material 3: tetrahydrofuran;

[0037] Raw material 4: Mixture of liquid cycloaliphatic epoxy resin and N,N'-dimethylformamide (DMF), mixture of liquid cycloaliphatic epoxy resin and N,N'-dimethylformamide (DMF) The volume ratio is 1 / 2;

[0038] Raw material 5: Triphenylphosphine (TPP);

[0039] Raw material 6: Liquid cycloaliphatic epoxy resin

[0040]In step I, the mass ratio of raw material 1 to raw material 2 is 1 / 70, the heating and reflux temperature is 100° C., and drying is carried out at 80° C. to constant weight to obtain surface carboxylated carbon nanotubes. In step II, the mass ratio of the surface carboxylat...

Embodiment 2

[0045] Raw material 1: multi-walled carbon nanotubes, purity >95%, diameter 10-20 nm, length 0.5-500 μm, produced by Shenzhen Nanometer Harbor Co., Ltd.;

[0046] Raw material 2: The ratio of mixed acid is concentrated sulfuric acid / concentrated nitric acid = 3 / 1 (volume ratio), all produced by Beijing Chemical Reagent Company;

[0047] Raw material 3: N,N'-dimethylformamide (DMF);

[0048] Raw material 4: a mixture of liquid trifunctional epoxy resin TGAP and N,N'-dimethylformamide (DMF), a liquid trifunctional epoxy resin TGAP and N,N'-dimethylformamide (DMF ) volume ratio is 1 / 2;

[0049] Raw material 5: tetraethylammonium bromide;

[0050] Raw material 6: liquid trifunctional epoxy resin TGAP;

[0051] In step I, the mass ratio of raw material 1 to raw material 2 is 1 / 140, the heating and reflux temperature is 90° C., and drying is carried out at 90° C. to constant weight to obtain surface carboxylated carbon nanotubes. In step II, the mass ratio of the surface carboxy...

Embodiment 3

[0057] Raw material 1: multi-walled carbon nanotubes, purity >95%, diameter 10-20 nm, length 0.5-500 μm, produced by Shenzhen Nanometer Harbor Co., Ltd.;

[0058] Raw material 2: The ratio of mixed acid is concentrated sulfuric acid / concentrated nitric acid = 2 / 1 (volume ratio), all produced by Beijing Chemical Reagent Company;

[0059] Raw material 3: acetone;

[0060] Raw material 4: a mixture of liquid tetrafunctional epoxy resin TGDDM and N,N'-dimethylformamide (DMF), liquid tetrafunctional epoxy resin TGDDM and N,N'-dimethylformamide (DMF ) volume ratio is 1 / 2;

[0061] Raw material 5: triethylamine;

[0062] Raw material 6: liquid tetrafunctional epoxy resin TGDDM;

[0063] In step I, the mass ratio of raw material 1 to raw material 2 is 1 / 350, the heating and reflux temperature is 90° C., and drying is carried out at 90° C. to constant weight to obtain surface carboxylated carbon nanotubes. In step II, the mass ratio of the surface carboxylated carbon nanotubes to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com