Fermentation production method of fidaxomicin

A technology of fidaxomicin and fermentation broth, which is applied in the field of microbial fermentation to produce antibiotics, can solve the problems of lack of delayed carbon and nitrogen sources in the medium, low yield of fermentation products, poor fermentation effect, etc., and achieves increasing the utilization rate of the medium , the effect of improving fermentation yield and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

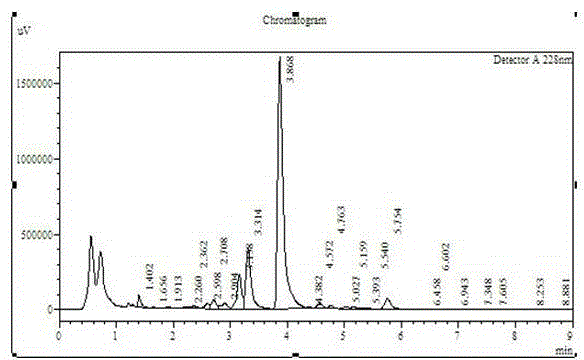

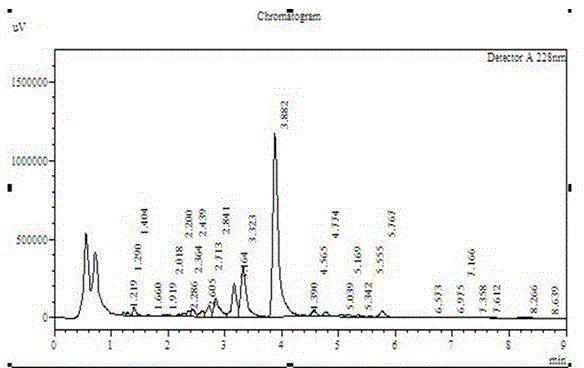

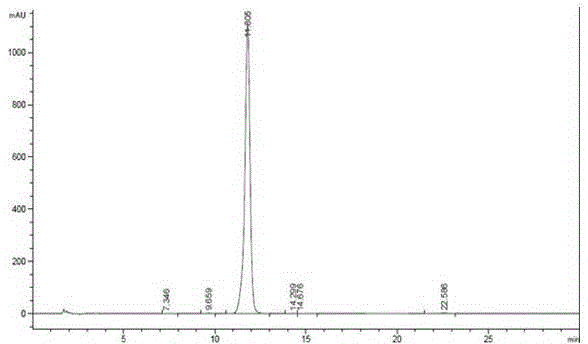

Image

Examples

Embodiment 1

[0029] Example 1 Batch-type addition of edible oil during fermentation

[0030] Prepare 300L seed medium in a 500L seed tank, sterilize at 120°C for 30 minutes, cool to 27°C, inoculate 48h seed-age shake flask seeds at an inoculum volume ratio of 0.1% of the seed medium volume, and incubate at 27°C for 28h.

[0031] Prepare 3500L fermentation medium in a 5000L fermenter, sterilize at 120°C for 30 minutes, then cool to 27°C, insert the vegetative inoculum into the above seed medium with an inoculation amount of 4% by volume of the fermentation medium, and control the temperature during the fermentation process The temperature is 27°C, the control pressure is 0.04Mpa, the control ventilation is 0.5VVM, and the control speed is 100rpm to ensure that the dissolved oxygen is above 30%.

[0032] The fermentation culture is continued, and after 48 hours, the dissolved oxygen in the fermenter drops to 32%, and gradually begins to rise again, and soybean oil is added to the fermenter...

Embodiment 2

[0033] Example 2 Continuous Addition of Edible Oil During Fermentation

[0034] Prepare 100L seed medium in a 200L seed tank, sterilize at 120°C for 30 minutes, cool to 27-29°C, insert 48h seed-age shake flask seeds at an inoculum volume ratio of 0.3% of the seed medium volume, and then incubate at 29°C for 36h .

[0035] Prepare 1400L fermentation medium in a 2000L fermenter, sterilize at 120°C for 30 minutes and then cool to 29°C, add the vegetative inoculum in the above seed medium according to the inoculum volume ratio of 8% of the fermentation medium volume, and control the temperature during the fermentation process The temperature is 29°C, the control pressure is 0.06Mpa, the control ventilation is 1.5VVM, and the control speed is 250rpm to ensure that the dissolved oxygen is above 30%.

[0036] Continue the fermentation culture. After 64 hours, the dissolved oxygen in the fermenter drops to 33%, and gradually starts to rise again. Take 24 hours as a time unit, and b...

Embodiment 3

[0037] Example 3 Adding edible oil intermittently during the fermentation process

[0038] Prepare 100L seed medium in a 200L seed tank, sterilize at 120°C for 30 minutes, then cool to 28°C, inoculate 48h-old shake flask seeds at an inoculum volume ratio of 0.2% of the seed medium volume, and then incubate at 28°C for 30h.

[0039] Prepare 700L fermentation medium in a 1000L fermenter, sterilize at 120°C for 30 minutes and then cool to 28°C, insert the vegetative inoculum into the above seed medium with an inoculation amount of 5% by volume of the fermentation medium, and control the temperature during the fermentation process At 28°C, control the pressure at 0.05Mpa, control the ventilation at 1.0VVM, and control the speed at 200rpm to ensure that the dissolved oxygen is above 30%.

[0040]The fermentation culture is continued, and the dissolved oxygen in the fermenter drops to 30% after 52 hours, and gradually begins to rise again. Add rapeseed oil to the fermenter every t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com