Method for improving beta-carotene produced from blakeslea trispora by virtue of organic acid

A technology of Brassella trispora and Brassella, applied in the field of β-carotene, can solve the problems of limited development, toxic and side effects, low product absorption rate, etc., and the method is simple, easy to implement, low in cost, and high in content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Incline culture: Prepare corn flour agar medium (corn flour 30g / L, malt flour 10g / L, agar powder 15g / L, pH value 7.2). Open the frozen glycerol tube, and take 15 μL of Blakeslea trispora (+) (purchased from the American Type Culture Collection (ATCC), number ATCC 14271 (+)), (-) (purchased from the U.S. Typical strain collection center (ATCC), the number is ATCC 14272 (-)) bacteria liquid, spread on corn flour agar medium, and cultivate at 28°C for 120h.

[0032] 2) Preparation of seed medium: Dissolve 47g of corn flour and 23g of soybean flour in 1000mL of deionized water, and gelatinize at 100°C for 20min. After cooling, add 2g of potassium dihydrogen phosphate, 0.5g of magnesium sulfate, 0.05g of anhydrous calcium chloride, and 0.09g of ferrous sulfate heptahydrate. After stirring and mixing, adjust the pH value to 6.2 with 40% sodium hydroxide solution, add deionized water to make up to 1000mL, dispense into 250mL Erlenmeyer flasks, and sterilize in an autoclave...

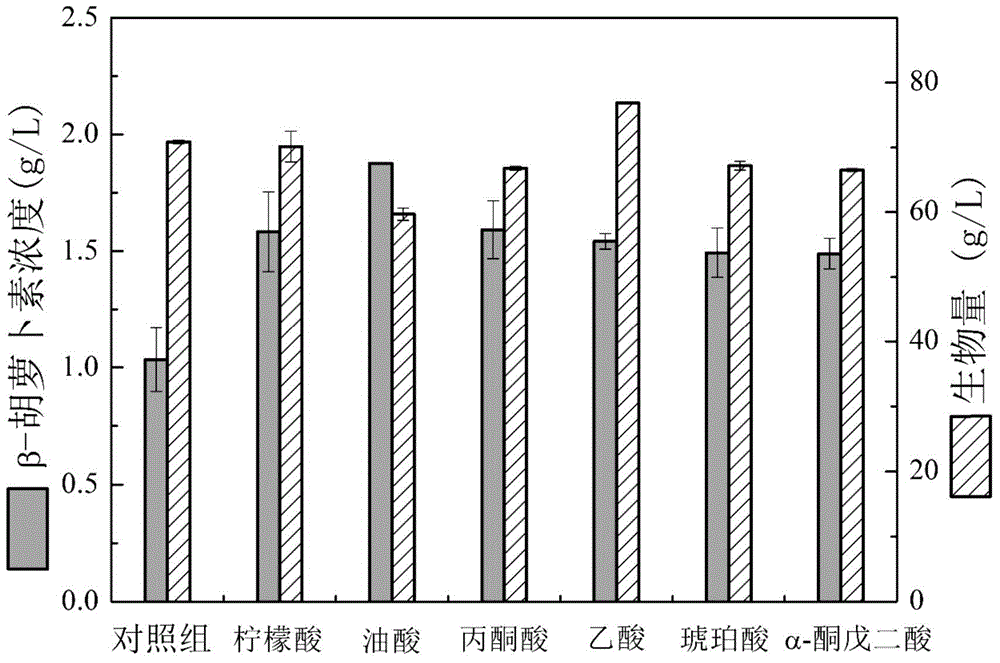

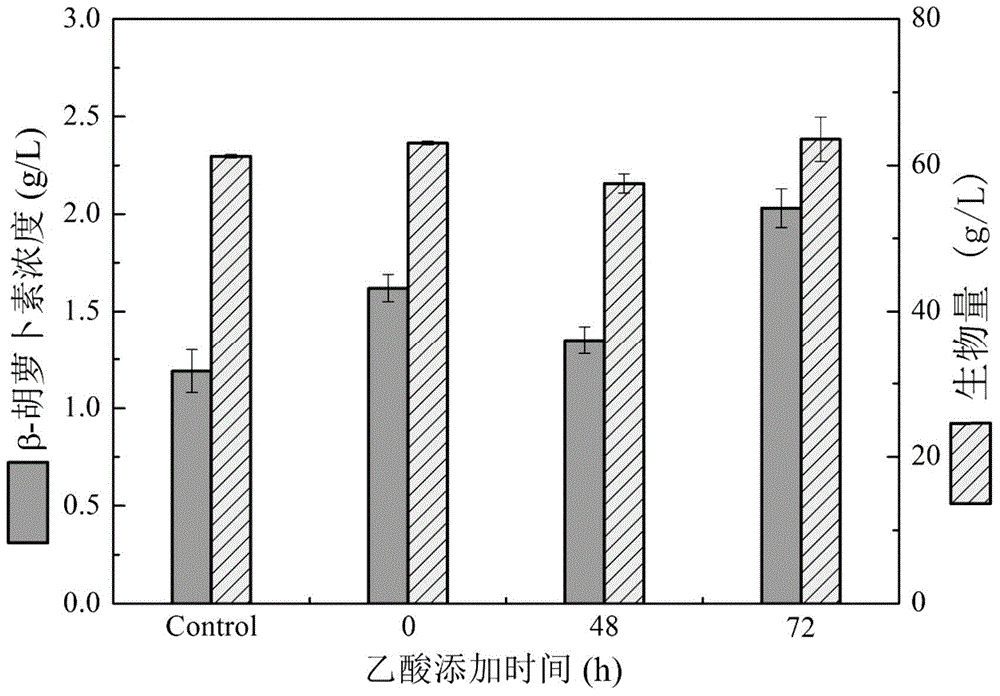

Embodiment 2

[0047] 1) Incline culture: Prepare corn flour agar medium (corn flour 30g / L, malt flour 10g / L, agar powder 15g / L, pH value 6.2). Open the frozen glycerol tube, and take 15 μL of Blakeslea trispora (+) (purchased from the American Type Culture Collection (ATCC), number ATCC 14271 (+)), (-) (purchased from the U.S. Typical strain collection center (ATCC), the number is ATCC 14272 (-)) bacteria liquid, spread on corn flour agar medium, and cultivate at 28°C for 120h.

[0048] 2) Preparation of seed medium: Dissolve 47g of corn flour and 23g of soybean flour in 1000mL of deionized water, and gelatinize at 100°C for 20 minutes. After cooling, add 2g potassium dihydrogen phosphate, 0.5g magnesium sulfate, 0.05g anhydrous calcium chloride, 0.09g ferrous sulfate heptahydrate, stir and mix well, adjust the pH value to 6.2 with 40% sodium hydroxide solution, add deionized Dilute water to 1000mL, dispense into 250mL Erlenmeyer flasks, and sterilize in a high-pressure steam sterilizer at...

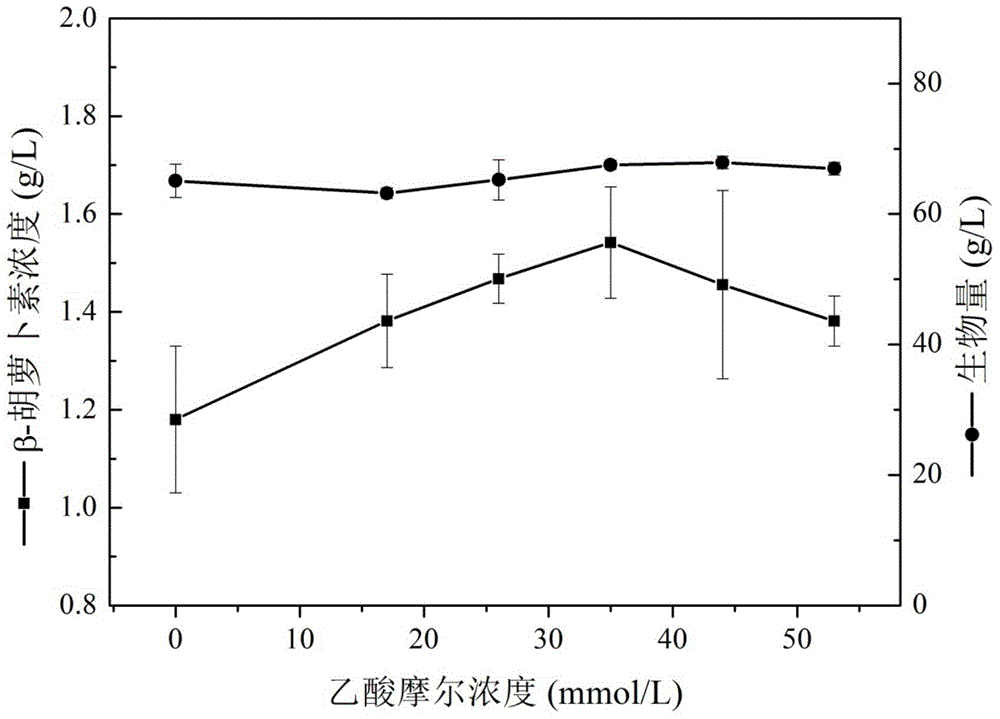

Embodiment 3

[0062]1) Incline culture: Prepare corn flour agar medium (corn flour 30g / L, malt flour 10g / L, agar powder 15g / L, pH value 6.2). Open the frozen glycerol tube, and take 15 μL of Blakeslea trispora (+) (purchased from the American Type Culture Collection (ATCC), number ATCC 14271 (+)), (-) (purchased from the U.S. Typical strain collection center (ATCC), the number is ATCC 14272 (-)) bacteria liquid, spread on corn flour agar medium, and cultivate at 28°C for 120h.

[0063] 2) Preparation of seed medium: Dissolve 47g of corn flour and 23g of soybean flour in 1000mL of deionized water, and gelatinize at 100°C for 20min. After cooling, add 2g of potassium dihydrogen phosphate, 0.5g of magnesium sulfate, 0.05g of anhydrous calcium chloride, and 0.09g of ferrous sulfate heptahydrate. After stirring and mixing, adjust the pH value to 6.2 with 40% sodium hydroxide solution, add deionized water to make up to 1000mL, dispense into 250mL Erlenmeyer flasks, and sterilize in an autoclave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com