Post-processing method of solar cell piece

A technology of solar cells and silicon wafers, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effects of improving uniformity and compactness, improving resistance to hidden cracks, and enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

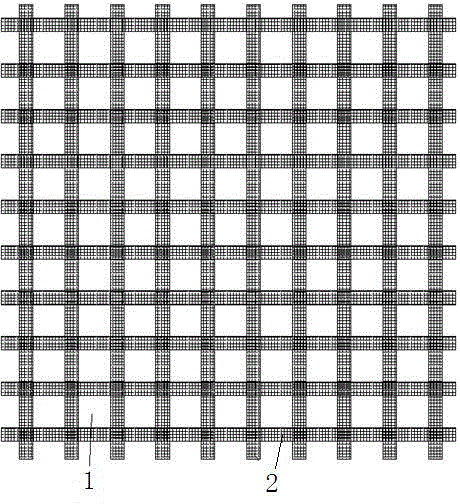

[0025] Select polysilicon wafer; 1) Surface structuring of silicon wafer, making emitter, peripheral etching, removal of phosphosilicate glass, silicon nitride film, silk screen front and back electrodes and back aluminum, sintering; 2) The battery obtained in step 1 Make a layer of non-stick coating with a thickness of 20 microns on the back of the sheet aluminum, and the non-stick coating is polytetrafluoroethylene resin; 3) Put the battery sheet obtained in step 2 into an annealing furnace, and pass in hydrogen gas , keep the temperature at 300°C for 220s. The non-stick coating is hollowed out with a grid structure, as shown in the attached picture of the instruction manual figure 1 As shown, the hollowed out area 1 is a square, the width of the grid structure hollowed out area 1 is 0.8 mm, and the width of the grid structure non-hollowed out area 2 is 1 mm.

Embodiment 2

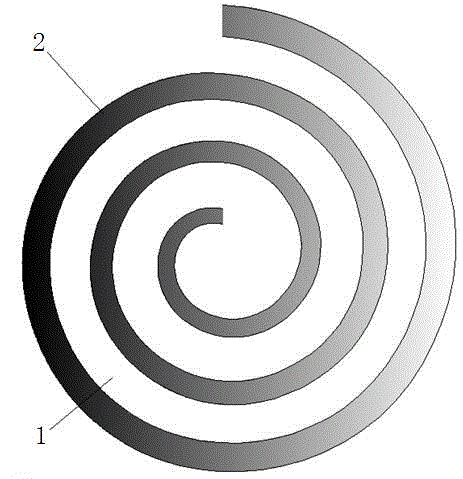

[0027] Select a single crystal silicon wafer; 1) Process the silicon wafer through surface structuring, making emitters, peripheral etching, removal of phosphosilicate glass, silicon nitride film, silk screen front and back electrodes and back aluminum, and sintering; 2) Step 1 Make a layer of non-stick coating with a thickness of 30 microns on the aluminum back field of the obtained battery sheet, and the non-stick coating is polyimide resin; 3) Put the battery sheet obtained in step 2 into an annealing furnace, pass through Hydrogen gas, keep the temperature at 200°C for 500s. The non-stick coating is hollowed out with a spiral structure, the average width of the hollowed out area 1 of the spiral structure is 2mm, and the average width of the non-hollowed out area 2 of the spiral structure is 2mm.

Embodiment 3

[0029] Select a single crystal silicon wafer; 1) Process the silicon wafer through surface structuring, making emitters, peripheral etching, removal of phosphosilicate glass, silicon nitride film, silk screen front and back electrodes and back aluminum, and sintering; 2) Step 1 A layer of non-stick coating with a thickness of 50 microns is made on the aluminum back field of the obtained cell, and the non-stick coating is silicone oil; 3) The cell obtained in step 2 is placed in an annealing furnace, and hydrogen gas is introduced to keep The temperature is 260°C, and the time is 400s. The non-stick coating is hollowed out with a grid structure, as shown in the attached picture of the instruction manual figure 1 As shown, the hollowed-out area 1 is elliptical, the average width of the grid-structured hollowed-out area 1 is 1.5mm, and the average width of the grid-structured non-hollowed-out area 2 is 3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com