Method for preparing high-purity nanometer lithium manganate

A nanometer lithium manganate and potassium permanganate technology, applied in electrical components, battery electrodes, circuits, etc., to achieve the effects of low energy consumption, large specific capacity and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The present embodiment comprises the following steps: preparing 40 mL of reaction solution and placing it in a hydrothermal kettle, wherein the reaction solution contains a mixed aqueous solution containing 0.48 g of potassium permanganate, 0.104 g of ascorbic acid, and 0.096 g of lithium hydroxide; Heat it at 180°C for 5 hours. After cooling to room temperature, wash and filter with suction to separate lithium manganate and dry it.

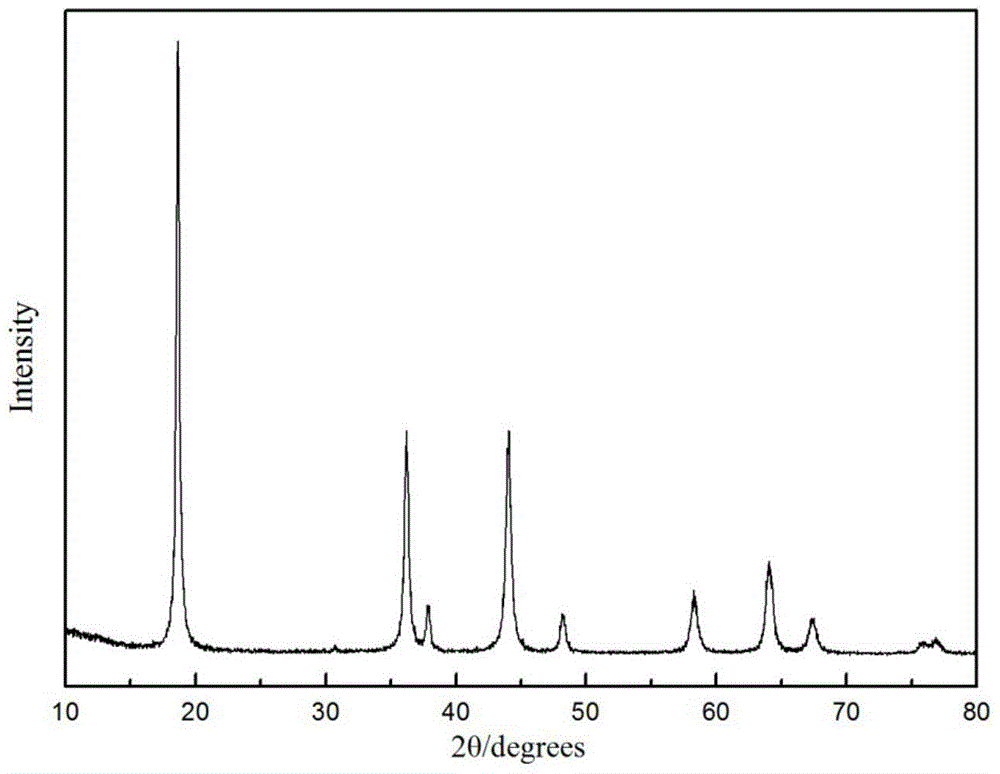

[0021] Such as figure 1 As shown, the nano-lithium manganese oxide prepared in this example is high-purity lithium manganate, and its purity is about 99.6%.

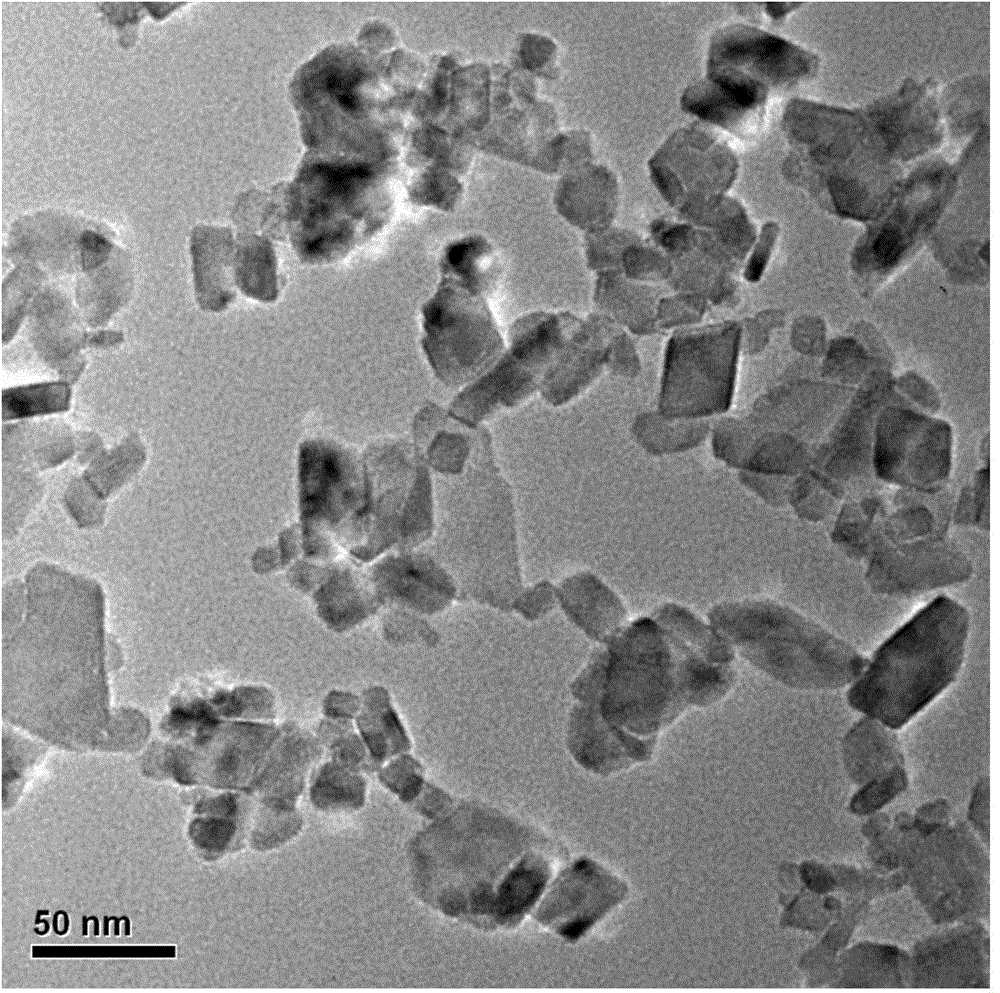

[0022] Such as figure 2 As shown, the lithium manganate particles prepared in this example are nanoscale particles with a size of about 50 nanometers and a uniform size distribution.

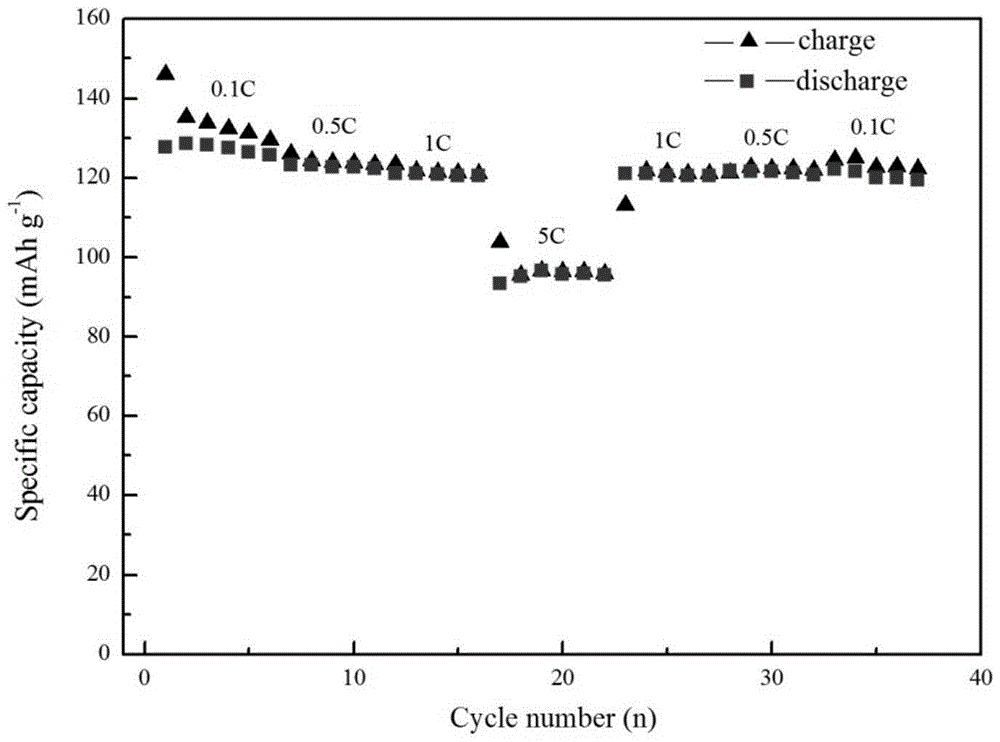

[0023] Such as image 3 and Figure 4 As shown, at different charge and discharge rates (0.1C, 0.5C, 1C and 5C), the charge and discharge performance of the prepared lithium manganate samples were...

Embodiment 2

[0025] This embodiment includes the following steps:

[0026] Prepare 80mL of reaction solution and place it in a hydrothermal kettle, wherein the reaction solution is a mixed aqueous solution containing 0.96g of potassium permanganate, 0.208g of ascorbic acid, and 0.192g of lithium hydroxide, then heat the hydrothermal kettle to 160°C and keep it warm for 8 hours. After cooling to room temperature, the lithium manganate was separated by washing and suction filtration, and dried.

[0027] The purity of the nano-lithium manganese oxide prepared in this example is about 99.3%.

[0028] The charge and discharge performance test was carried out on the prepared lithium manganese oxide sample. The charge-discharge cycle test results show that the specific capacities at 0.1C and 5C charge-discharge are about 124 and 82mAh g, respectively. ‐1 .

Embodiment 3

[0030] This embodiment includes the following steps:

[0031] Prepare 80mL of reaction solution and place it in a hydrothermal kettle, wherein the reaction solution is a mixed aqueous solution containing 0.96g of potassium permanganate, 0.18g of ascorbic acid, and 0.192g of lithium hydroxide, then heat the hydrothermal kettle to 200°C and keep it warm for 4 hours. After cooling to room temperature, the lithium manganate was separated by washing and suction filtration, and dried.

[0032] The purity of the nano-lithium manganese oxide prepared in this example is about 99.1%.

[0033] The charge and discharge performance test was carried out on the prepared lithium manganese oxide sample. The charge-discharge cycle test results show that the specific capacities at 0.1C and 5C charge-discharge are about 120 and 73mAh g, respectively. ‐1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com