Magnetism recyclable nano adsorbent, preparation method and application thereof

A nano-adsorption and adsorbent technology, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effects of low production cost, simple experimental operation, and favorable recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Zinc salt, iron salt, NH 4 Preparation of zinc ferrite synthesized under the condition that the molar ratio of F is 1:2:2

[0020] Dissolve zinc salt, iron salt, NH at a molar ratio of 1:2:2 in ethylene glycol 4 F. Pour it into a solvothermal reaction kettle, and keep it warm at 150-200°C for 8-16 hours. Afterwards, the reaction product is washed and dried, and put into a muffle furnace for calcination at a heating rate of 2-8°C / min and 300-800°C for 1-3 hours. Wait for natural cooling to obtain zinc ferrite powder adsorbent.

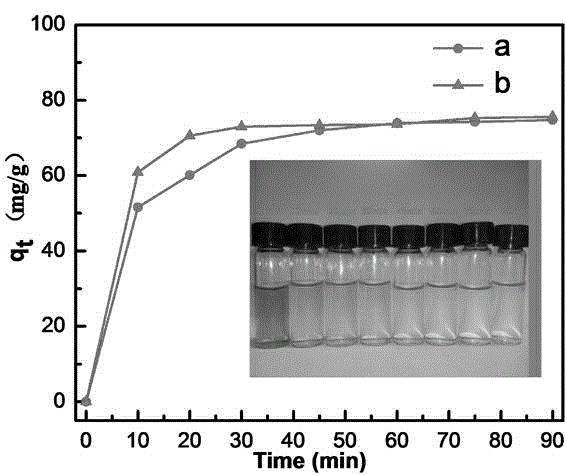

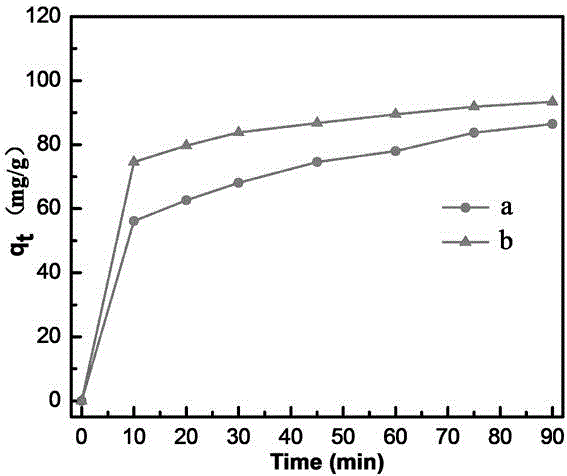

[0021] figure 1 (a) Zinc salt, iron salt, NH 4 The molar ratio of F is 1:2:2. The adsorption of Congo red to zinc ferrite synthesized by F is 60min, and the adsorption amount is about 75mg / g. figure 2 (a) Zinc salt, iron salt, NH 4 The molar ratio of F is 1:2:2 synthesized zinc ferrite to Pb 2+ The adsorption capacity is about 80mg / g.

Embodiment 2

[0023] Zinc salt, iron salt, NH 4 Preparation of Zinc Ferrite Synthesized under the Molar Ratio of F 1:2:4

[0024] Dissolve zinc salt, iron salt, NH in ethylene glycol with a molar ratio of 1:2:4 4 F. Pour it into a solvothermal reaction kettle, and keep it warm at 150-200°C for 8-16 hours. Afterwards, the reaction product is washed and dried, and put into a muffle furnace for calcination at a heating rate of 2-8°C / min and 300-800°C for 1-3 hours. Wait for natural cooling to obtain zinc ferrite powder adsorbent.

[0025] figure 1 (b) is zinc salt, iron salt, NH 4 The molar ratio of F is 1:2:4, and the adsorption time of Congo red to zinc ferrite is 40min, and the adsorption amount is about 75mg / g. The illustration in Figure (1) shows zinc salt, iron salt, NH 4 The adsorption photos of Congo red on zinc ferrite with a molar ratio of F of 1:2:4, it can be seen that after 40 minutes of adsorption, it is basically close to transparent. figure 2 (b) is zinc salt, ir...

Embodiment 3

[0027] Preparation of Magnesium Ferrite with Hydrothermal Temperature of 180℃

[0028] Dissolve the magnesium salt and iron salt with a molar ratio of 1:2 in ethylene glycol successively. Pour it into a solvothermal reaction kettle, and keep it warm at 180°C for 8-16 hours. Afterwards, the reaction product is washed and dried, and put into a muffle furnace for calcination at a heating rate of 2-8°C / min and 300-800°C for 1-3 hours. Wait for natural cooling to obtain magnesium ferrite powder adsorbent.

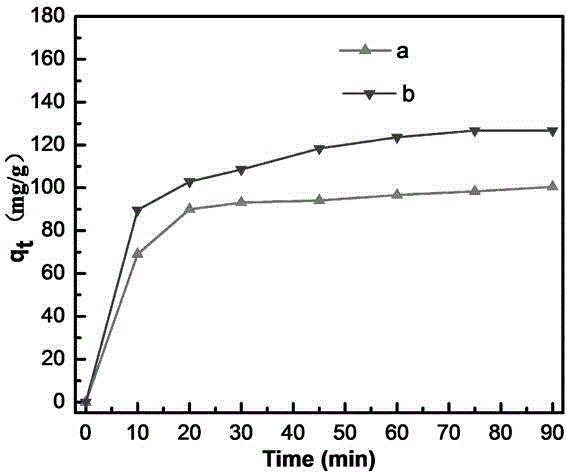

[0029] image 3 In (a) is magnesium ferrite to Pb 2+ The time required to reach equilibrium is 20 minutes, and the adsorption amount is 90 mg / g. (b) is the adsorption of magnesium ferrite to Congo red. The time required to reach equilibrium is 60 minutes, and the adsorption amount is about 125 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com