Bus brace and pantograph brace porcelain insulator on roof of electric locomotive

A technology for electric locomotives and insulators, applied to electric vehicles, current collectors, vehicle components, etc., to achieve the effects of reducing collision and capture rates, improving performance, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

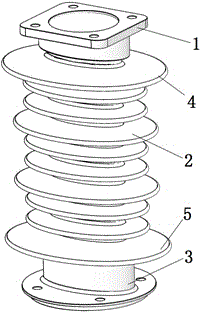

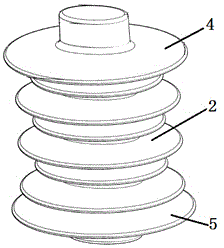

[0040] attached figure 1 A technical embodiment of the present invention is given. It can be seen from the accompanying drawings that the present invention is a porcelain insulator for the roof of an electric locomotive, including an upper attachment 1, a non-circular porcelain part 2, and a lower attachment 3; the non-circular porcelain part 2 is made of high-strength ceramics, and the non-circular Porcelain piece 2 is the shape of multi-layer umbrellas and big and small umbrellas that are separated in an orderly manner. The upper layer of homogeneous self-cleaning glaze; the upper attachment 1 and the lower attachment 3 are made of corrosion-resistant high-strength metal materials, and their cooperation with the non-circular porcelain part 2 is also non-circular; the busbar pillars and During the operation of the pantograph support porcelain insulator, the non-circular long axis direction is installed along the direction of the vehicle. This arrangement is beneficial to eli...

Embodiment 2

[0055] The basic structure of the second embodiment is the same as that of the first embodiment, except that the tower insulators in which the multi-layer sheds and the big and small umbrellas are separated in an orderly manner are that the shed length of any longitudinal section of the uppermost shed of the insulator is longer than that of the same longitudinal section below it. The umbrella length of the sectional skirt.

[0056] The formula has also been adjusted, the porcelain insulator is made of high alumina porcelain, AL 2 o 3 The content is 61~65%, and pure industrial alumina powder is used, the sintering temperature is SK61310℃±5℃, and the bulk density is 3.0~3.5t / m 3 .

[0057] The porcelain insulator is made according to the following material formula (calculated by weight percentage):

[0058] Activated calcined alumina powder 59%

[0059] Kaolin 18%

[0060] Feldspar 12%

[0061] Talc 5%

[0063] Among them, 325~1250 mesh, fi...

Embodiment 3

[0065] The basic structure of the third embodiment is the same as that of the first embodiment, except that the structure is a hollow structure, and the formula is adjusted. The material of the porcelain insulator is high alumina porcelain, AL 2 o 3 The content is 61~65%, and pure industrial alumina powder is used, the sintering temperature is SK61310℃±5℃, and the bulk density is 3.0~3.5t / m 3 .

[0066] The porcelain insulator is made according to the following material formula (calculated by weight percentage):

[0067] Activated calcined alumina powder 57%

[0068] Kaolin 20%

[0069] Feldspar 10%

[0070] Talc 8%

[0072] Among them, 325~1250 mesh, fineness≦2um≧85% pure industrial alumina is used as the main raw material; screening plasticity index≧2.0, plasticity index≧20, dry strength≧3 / Mpa, aluminum oxide (AL 2 o 3 ) content≧37%, Fe 2 o 3 Kaolin with a content of ≦0.8%, and an appropriate amount of zirconium silicate to increase t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extension distance | aaaaa | aaaaa |

| Extension distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com