Magnesium sulfite cement and preparation method thereof

A technology of magnesium sulfite and manufacturing method, applied in the field of cement and its manufacturing, to achieve the effects of low overall production cost, cheap price and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0039] Preparation example (magnesium oxide method flue gas desulfurization produces magnesium sulfite raw material)

[0040] The desulfurizer magnesium oxide powder is added to industrial tap water to make desulfurizer slurry-magnesium hydroxide slurry, and pumped to the desulfurization tower for absorbing sulfur dioxide in the flue gas in the sulfur dioxide absorption spray area.

[0041] The flue gas from the coal-fired boiler of the power plant (adjusting the oxygen content to 6vt%) enters the interior of the desulfurization tower from the lower part of the desulfurization tower. During the rising process of the flue gas, it is in contact with the sulfur dioxide absorption spray area, and the flue gas is discharged from the top of the desulfurization tower. The sulfur dioxide absorption spraying area sprays desulfurizer slurry to absorb sulfur dioxide in the flue gas.

[0042] Magnesium sulfite-containing absorption product formed by the desulfurizer slurry after absorbin...

Embodiment 1-5

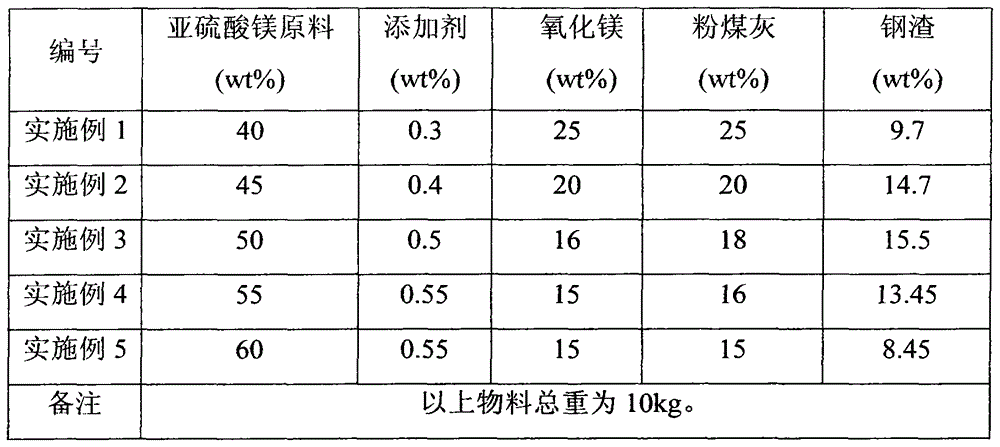

[0050] Mix the above-mentioned magnesium sulfite raw material with the additive (sodium dihydrogen phosphate) in proportion, add 250mL of water during the mixing process, then add magnesium oxide, fly ash and steel slag in sequence in proportion, and grind it into 300 mesh in a ball mill, and discharge That is, magnesium sulfite cement is obtained. See the table below for detailed parameters.

[0051]

[0052]

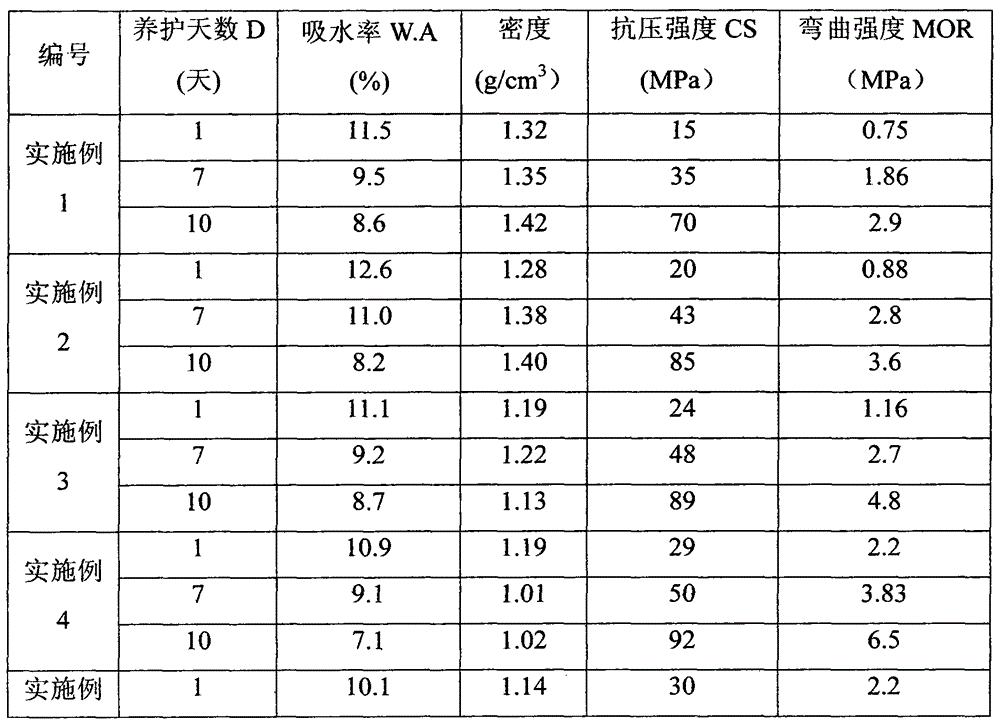

[0053] Add 0.9 kg of water to the above magnesium sulfite cement, and stir in a mixer to obtain a cement slurry. Put this slurry into a mold with a size of 30×30×120 mm to make a cement test block. After the specified number of days of curing, test according to the GB177-85 method, and the results are shown in the table below.

[0054]

[0055]

[0056]

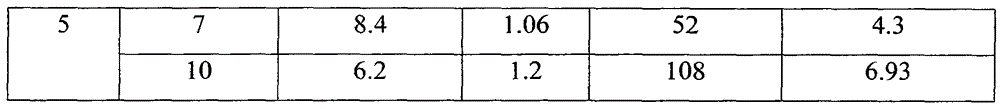

[0057] Add 0.8 kg of water to the magnesium sulfite cement, and stir evenly to prepare cement slurry. Put this slurry into a mold with a size of 30×30×120 mm to make a cement test block. Let it stand ...

Embodiment 1

[0058] The product of Example 1 has a maximum temperature of 180° C. during curing. The product is immersed in water for 24 hours, and then placed in a dry environment at 30°C for 24 hours, a total of 5 cycles, and the dissolution rate does not exceed 4%. This shows that magnesium sulfite and magnesium oxide have a significant protective effect on the 517 crystal phase (basic magnesium sulfate cement).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com