Extrusion grade foaming PP/PE material and preparation method thereof

An extrusion-grade foaming agent technology, applied in the field of extrusion-grade foamed PP/PE materials and their preparation, can solve problems such as poor wear resistance, poor mechanical properties, and poor compatibility between PP and PE , to achieve good mechanical properties, high productivity, and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1, an extrusion-grade foamed PP / PE material provided in this example, which is composed of the following mass percentages of raw materials: PP 10%, SEBS 8.2%, PE 59% , white oil 15%, compatibilizer 3%, anti-scratch modifier 2%, coupling agent 0.6%, expansion agent 0.4%, special foaming agent 0.6%, antioxidant 0.4, processing aid 0.8%.

[0031] The compatibilizer is at least one of styrene-acrylonitrile-glycidyl methacrylate copolymer, terpolymer of styrene-acrylonitrile-maleic anhydride, and PP-g-MAH. The antioxidant is β-(4-hydroxyphenyl-3,5-di-tert-butyl) n-octadecyl propionate, tetrakis (β-(3,5-di-tert-butyl-4-hydroxy At least one of pentaerythritol phenyl)propionate and tris(2,4-di-tert-butylphenyl)phosphite. The processing aid is pentaerythritol stearate or EBS.

[0032] A kind of preparation method of above-mentioned extrusion grade foamed PP / PE material, it comprises the following steps:

[0033] (1) PP, SEBS, PE, white oil, compatibilizer, anti-scratc...

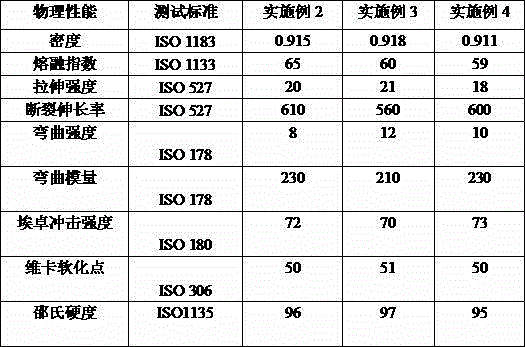

Embodiment 2

[0035] Example 2, an extrusion-grade foamed PP / PE material provided in this example and its preparation method, which is basically the same as Example 1, the difference is that it consists of the following raw materials in mass percentage: PP 16%, SEBS 7%, PE 61.7%, white oil 7%, compatibilizer 3%, anti-scratch modifier 2.5%, coupling agent 0.6%, expansion agent 0.5%, special foaming agent 0.5%, antioxidant 0.4 %, processing aid 0.8%.

Embodiment 3

[0036] Example 3, an extrusion-grade foamed PP / PE material provided in this example and its preparation method, which is basically the same as Example 1, the difference is that it consists of the following raw materials in mass percentage: PP 30%, SEBS 1%, PE 50%, white oil 14%, compatibilizer 1%, anti-scratch modifier 1%, coupling agent 1%, expansion agent 0.4%, special foaming agent 0.5%, antioxidant 1 %, processing aid 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com