Alkali-resistant primer and preparation method thereof

An anti-alkali primer and emulsion technology, which is applied in the field of architectural decoration coatings, can solve the problems of inability to prevent alkali return and no sealing effect, and achieve the effects of penetrating ability, preventing wall return to alkali, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

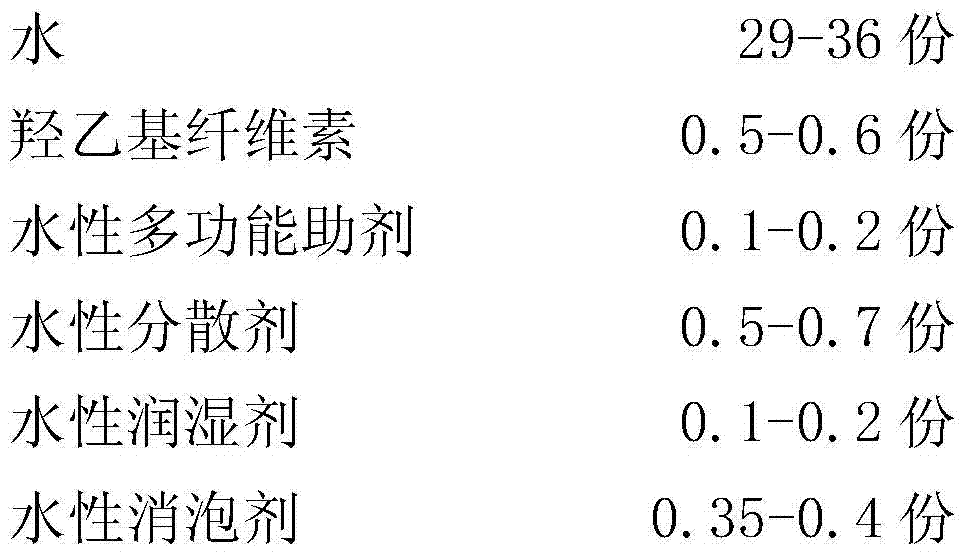

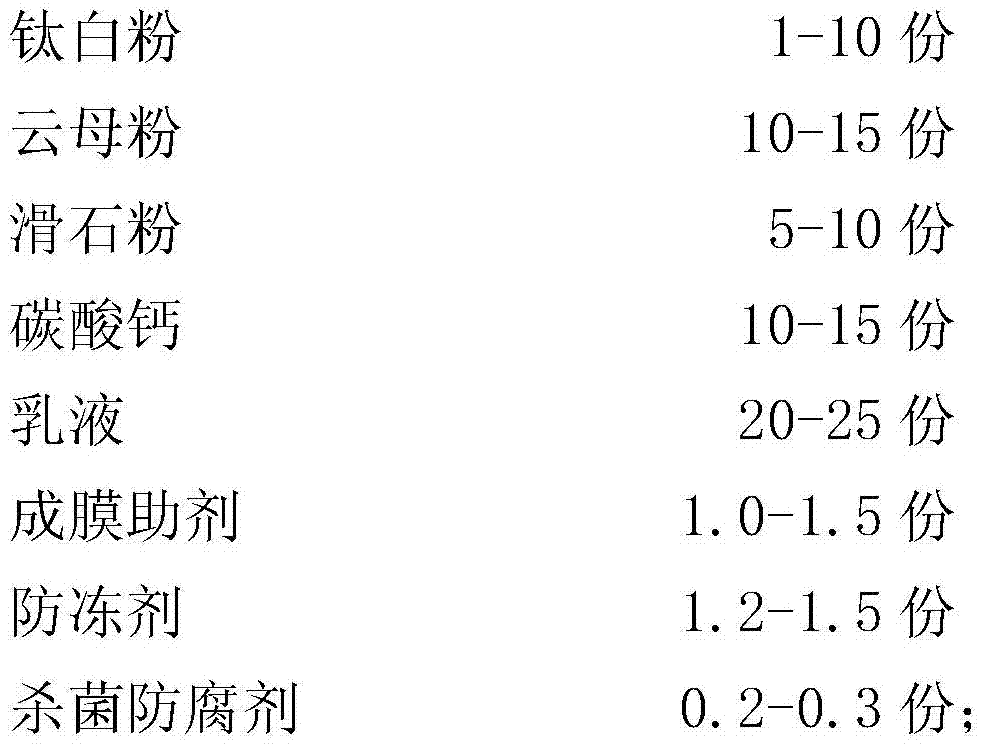

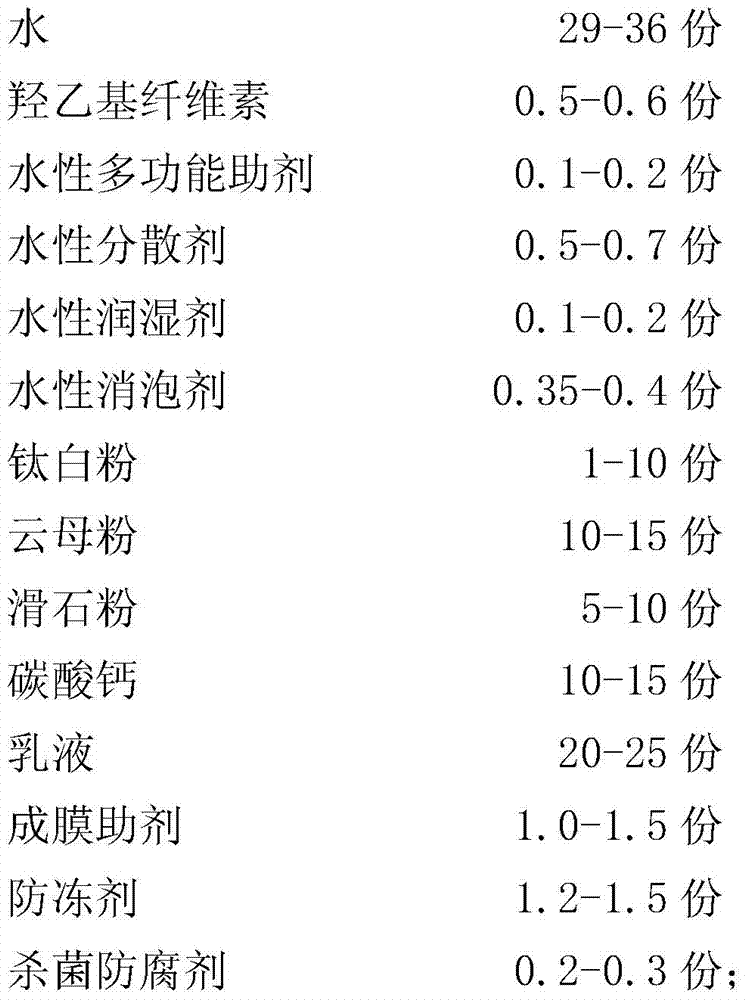

[0028] An anti-alkali primer, prepared from the following components and ratios in parts by weight:

[0029]

[0030] The emulsion is butadiene-styrene copolymer emulsion.

[0031] A kind of preparation method of anti-alkali primer, it comprises the following steps carried out in sequence:

[0032] (1) Add 29-36 parts of water into the dispersing tank, add 0.5-0.6 parts of hydroxyethyl cellulose and 0.1-0.2 parts of water-based multifunctional additives in turn under the stirring state of 350-550r / min, and stir for 1min-3min ;

[0033] (2) After increasing the rotating speed to 800-1000r / min, add 0.5-0.7 parts of water-based dispersant, 0.1-0.2 parts of water-based wetting agent, 0.35-0.4 parts of water-based defoamer, 1-10 parts of titanium dioxide, 10 -After 15 parts of mica powder, 5-10 parts of talc powder, and 10-15 parts of calcium carbonate, increase the speed again to 1800-2000r / min and disperse at this speed for 15min-20min, then test until the system fineness≤60...

Embodiment 1

[0037] Embodiment 1: a kind of anti-alkali primer, is formulated by following component and weight and number ratio:

[0038]

[0039] A kind of preparation method of anti-alkali primer, it comprises the following steps carried out in sequence:

[0040] (1) Add 32.1 parts of water into the dispersing tank, add 0.5 parts of hydroxyethyl cellulose and 0.1 parts of water-based multifunctional additives in sequence under stirring at 550r / min, and stir for 1 minute;

[0041] (2) After increasing the speed to 1000r / min, add 0.6 parts of water-based dispersant, 0.1 part of water-based wetting agent, 0.35 parts of water-based defoamer, 5 parts of titanium dioxide, 12 parts of mica powder, 8 parts of talc powder, 15 parts After adding calcium carbonate, increase the rotating speed to 2000r / min and disperse at this rotating speed for 15min, then detect until the system fineness≤60;

[0042](3) Add 23 parts of emulsion, 1.5 parts of film-forming aids, 1.5 parts of antifreeze, and 0.2...

Embodiment 2

[0044] Embodiment 2: a kind of anti-alkali primer, is formulated by following component and weight and number ratio:

[0045]

[0046] The preparation method of above-mentioned anti-alkali primer, it comprises the following steps carried out in sequence:

[0047] (1) Add 36 parts of water into the dispersion tank, add 0.5 part of hydroxyethyl cellulose and 0.1 part of water-based multifunctional additive in sequence under stirring at 350r / min, and stir for 3 minutes;

[0048] (2) After increasing the speed to 800r / min, add 0.5 parts of water-based dispersant, 0.1 part of water-based wetting agent, 0.38 parts of water-based defoamer, 1 part of titanium dioxide, 15 parts of mica powder, 10 parts of talc powder, 14 parts After adding calcium carbonate, increase the rotating speed to 1800r / min and disperse at this rotating speed for 20min, then detect until the fineness of the system is ≤60;

[0049] (3) Add 20 parts of emulsion, 1.0 part of film-forming aid, 1.2 part of antif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com